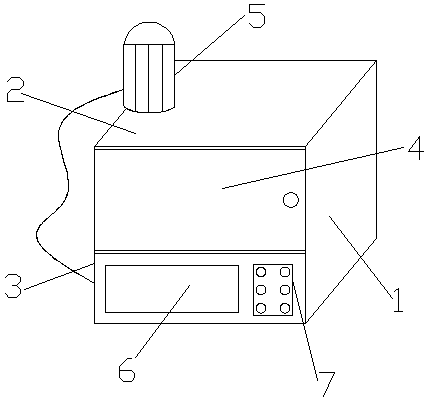

Dental denture soft alloy sintering furnace

A technology for sintering furnaces and dentures, which is applied in the direction of furnace, charge, electric furnace heating, etc. It can solve the problems of uniform baking of dentures, loose connection of single teeth of dentures, uneven heating, etc., to achieve high humanization and intelligence, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

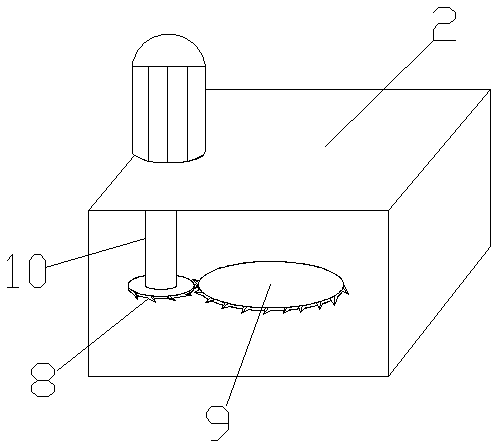

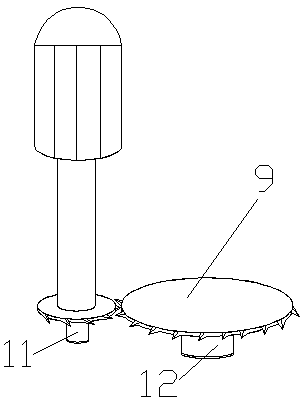

[0018] As a preferred embodiment of the present invention, the fitting height between the driving disc 8 and the heating disc 9 is the same, and the size and number of the fitting teeth between the driving disc 8 and the heating disc 9 are the same. Through the same structure and number of interlocking teeth between the transmission plate and the heating plate, the meshing rotation of the rods is realized, and the height of the transmission plate and the heating plate are consistent to ensure the tightness of the interlocking structure and the stability during the rotation.

[0019] As a preferred embodiment of the present invention, the first rotating screw 11 and the second rotating screw 12 are respectively consistent with the fixed connection structure of the transmission plate 8 and the heating plate 9. The same connection structure effectively ensures the consistency of rotation between the entire rotary connection, and at the same time ensures the same height of engagement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com