Flexible display device and manufacturing method thereof

A flexible display device and flexible display technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as short circuit of metal wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background section, in the prior art, photoresist remains between the metal traces due to the slope angle of the bending area, which leads to a short circuit between the metal traces.

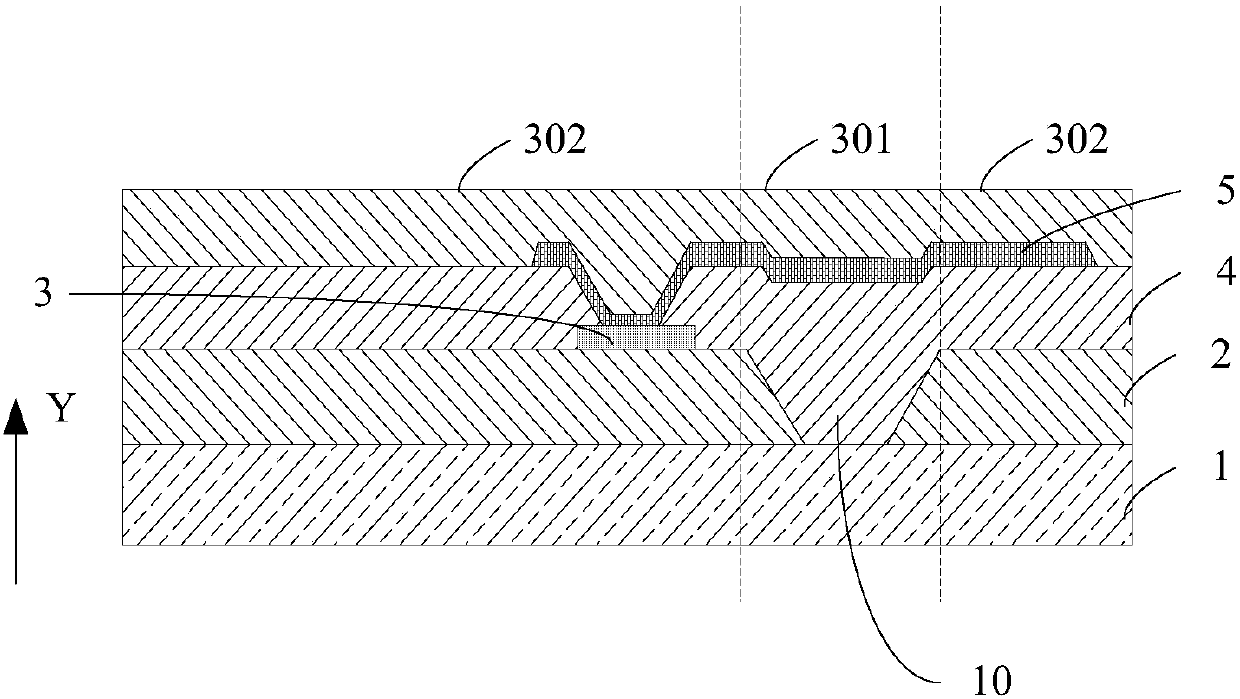

[0037] Based on this, the present invention provides a flexible display panel, such as image 3 As shown, according to the state of use of the flexible display panel, it can be divided into a bending area 301 and a non-bending area 302 . From the vertical hierarchical structure of the flexible display panel, it may include: a flexible substrate 1 , an inorganic layer 2 , a first metal wiring 3 , a planarization layer 4 and a second metal wiring 5 .

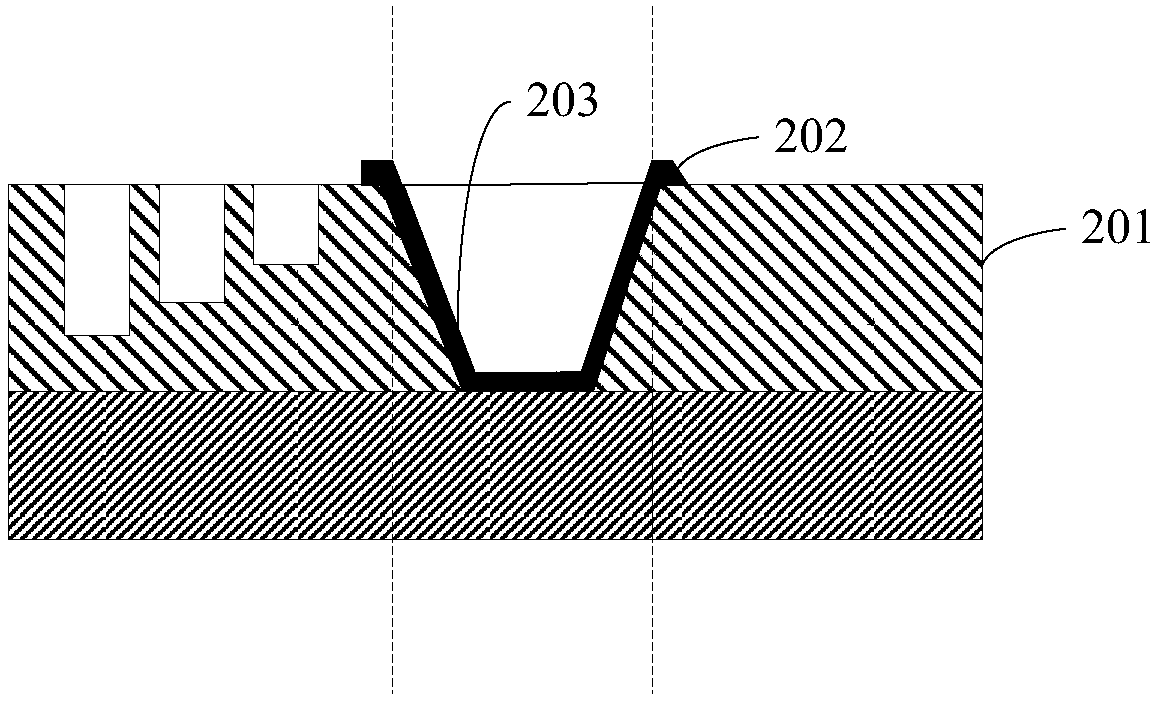

[0038] Specifically, please combine Figure 4 , Figure 4 A schematic diagram of the specific structure of each layer in a flexible display panel provided in this embodiment, wherein the inorganic layer 2 may include a buffer layer 401, a gate insulating layer 402, a first insulating layer 403, and a source-drain insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com