Operation control method of dividing wall tower

A technology of operation control and dividing wall tower, applied in the field of operation control of dividing wall tower, can solve the problems of difficult operation and control of dividing wall tower, difficult control of product quality and yield, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

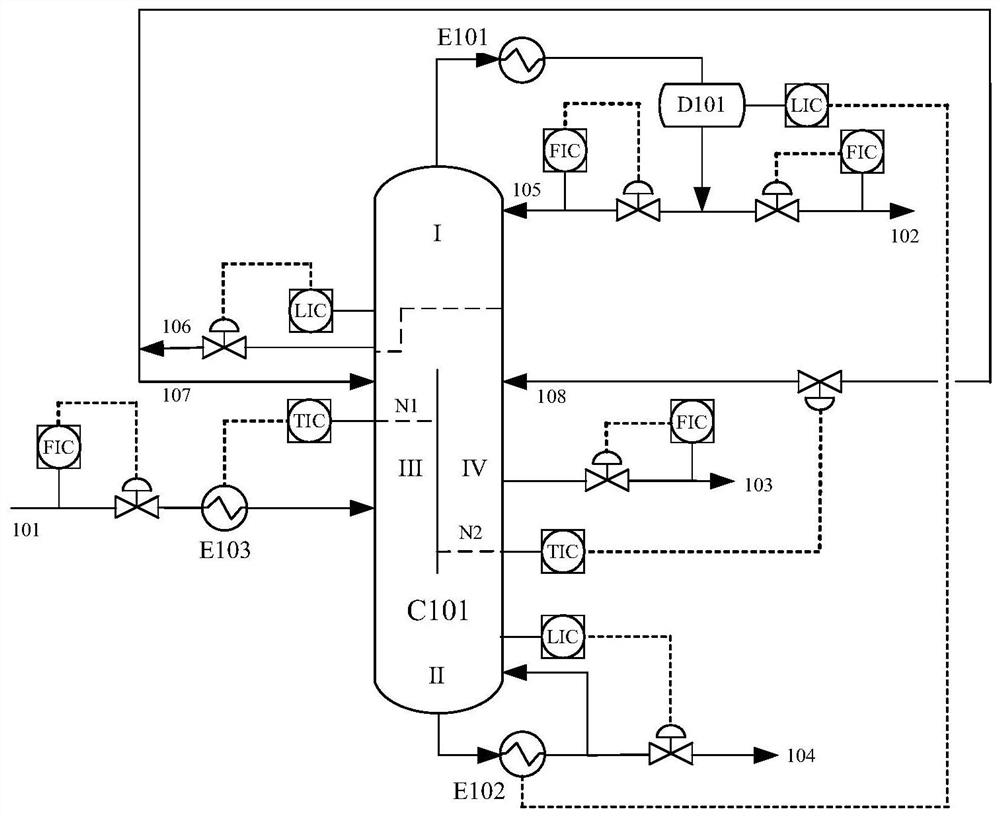

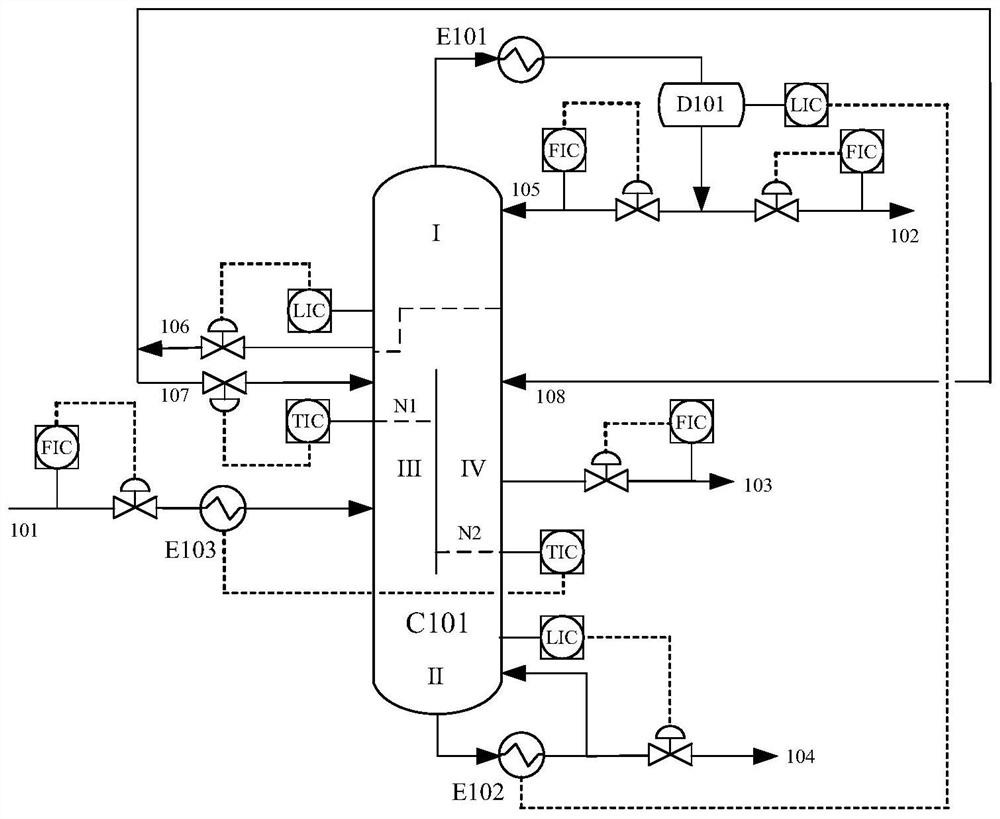

Embodiment 1

[0035] Using the benzene / toluene / mixed xylene material as the raw material, its composition in weight percentage is 12.80% benzene+70.69% toluene+16.51% mixed xylene. Based on the feed flow rate of 80g / min, press figure 1 The illustrated dividing wall column operation control method is used to separate, obtain benzene product from the top of the column, obtain toluene product from the side line, and obtain mixed xylene product from the tower still. Wherein the total number of theoretical plates of the dividing wall column is 70, the number of theoretical plates of the common rectifying section is 15, the number of theoretical plates of the feed side and the product side of the dividing wall section is 35, and the raw materials from the feeding side 1 of the dividing wall section are The 23rd theoretical plate counted from top to bottom enters, and toluene is extracted from the 17th theoretical plate counted from top to bottom from the product side III of the wall section. The ...

Embodiment 2

[0037] Using the benzene / toluene / mixed xylene material as the raw material, its composition in weight percentage is 33.85% benzene+54.61% toluene+11.54% mixed xylene. Based on the feed flow rate of 80g / min, press figure 1 The dividing wall column operation control method is shown for separation, wherein the total theoretical plate number of the dividing wall column is 70, the theoretical plate number of the common rectifying section is 20, and the theoretical plate number of the feed side and product side of the dividing wall section is 70. 30, the raw material enters from the 17th theoretical plate counted from top to bottom from the feed side I of the sub-wall section, and the toluene is extracted from the 15th theoretical plate from the top to the bottom of the sub-wall section product side III, and the operating pressure is constant. The control temperature of the sensitive plate N1 on the feed side and the sensitive plate N2 on the product side of the wall section are 108...

Embodiment 3

[0039] Taking ethanol / isobutanol / n-amyl alcohol mixture as raw material, its composition in weight percentage is 12.80% ethanol+70.69% isobutanol+16.51% n-amyl alcohol. Based on the feed flow rate of 80g / min, press figure 1 The illustrated dividing wall column operation control method is used for separation, obtaining ethanol product from the top of the column, isobutanol product from the side line, and n-amyl alcohol product from the column still. The structural parameters of the dividing wall column are the same as those in Example 1, the operating pressure is normal pressure, and the control temperatures of the sensitive plate N1 on the feed side of the divided wall section and the sensitive plate N2 on the product side are 105.7 °C and 108.0 °C, respectively. The output, and the flow rate of the reflux liquid at the top of the tower are controlled to be 10.2g / min, 56.5g / min, 117.3g / min respectively, and the liquid levels of the tower top condensation tank, the liquid colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com