Solar battery cell series welding equipment and series welding method

A technology for solar cells and cells, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., and can solve the problem that the position of the welding strip and the grid line of the battery is easy to shift, the whitening range of the welding strip exceeds the range, and affects the battery string. Welding quality and other issues, to achieve high automation performance, avoid offset, avoid the effect of relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

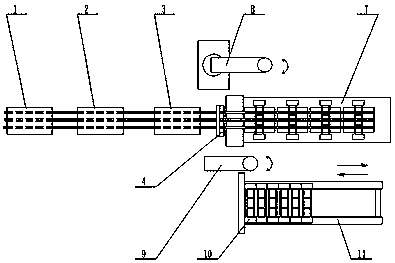

[0036] In the embodiment of the present invention, with figure 1 The direction to the left in the middle is the rear, with the attached figure 1 The direction to the right in the middle is the front, with the attached figure 1 The direction perpendicular to the inside of the paper is inside, and the direction perpendicular to the outside of the paper is outside.

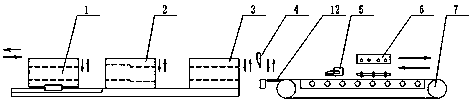

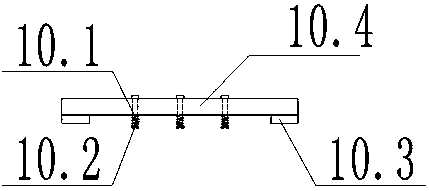

[0037] like figure 1 , 2 Shown in and 3: a kind of solar cell serial welding equipment, including a frame, a ribbon unwinding mechanism (not shown in the accompanying drawings) and a ribbon pulling mechanism 5 for pulling the ribbon are arranged on the rack , the first pressing mechanism 1 for pressing the welding ribbon, the bending mechanism 2 for bending the welding ribbon, the first pressing mechanism for pressing the welding ribbon, and the The second pressing mechanism 3, the ribbon cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com