Method for continuously synthesizing N,N-diethyl-m-methylbenzamide

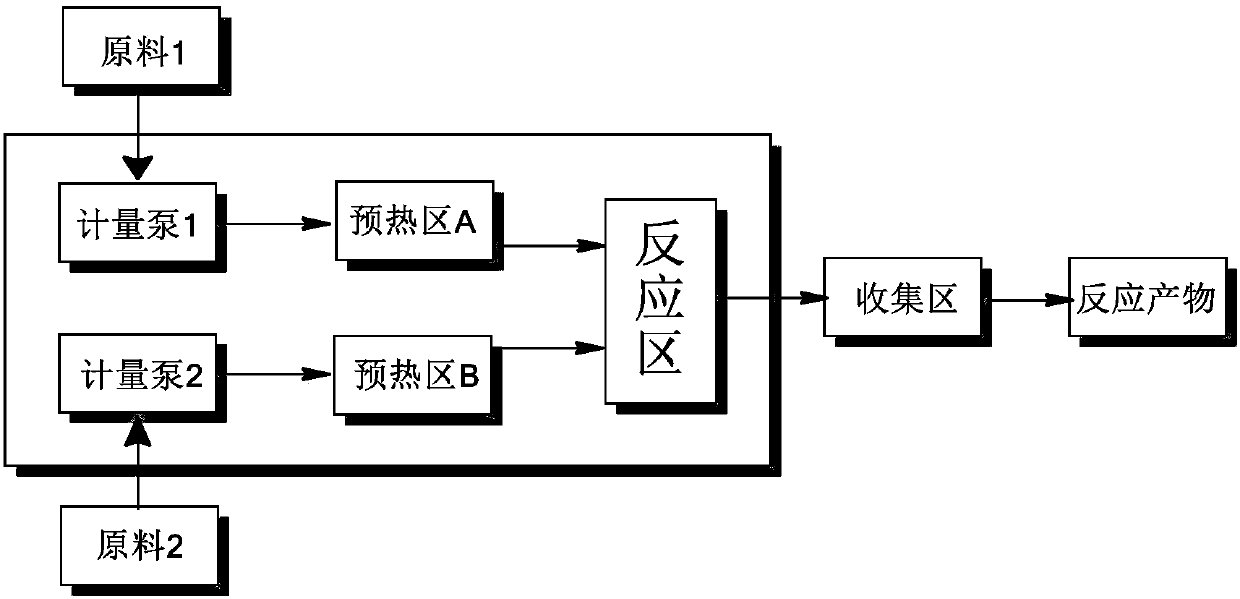

A technology of toluamide and toluyl chloride, which is applied in the field of continuous synthesis of N,N-diethyl-m-toluamide, can solve the problem of high requirements for reaction equipment, poor mass and heat transfer effects, and reaction problems. Harsh conditions and other problems, to achieve the effect of shortening the production time of the process, short reaction time, safe and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

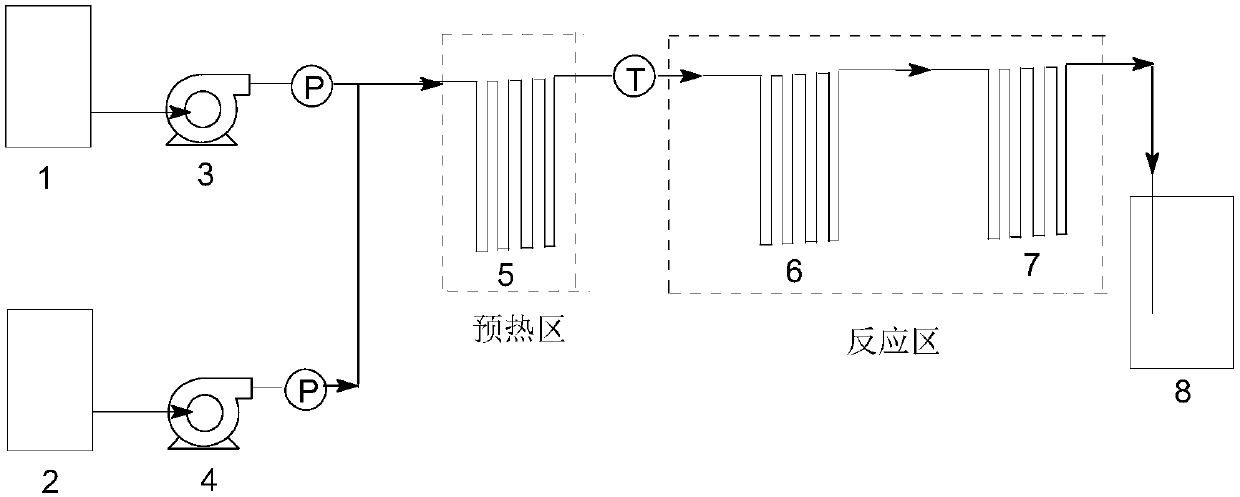

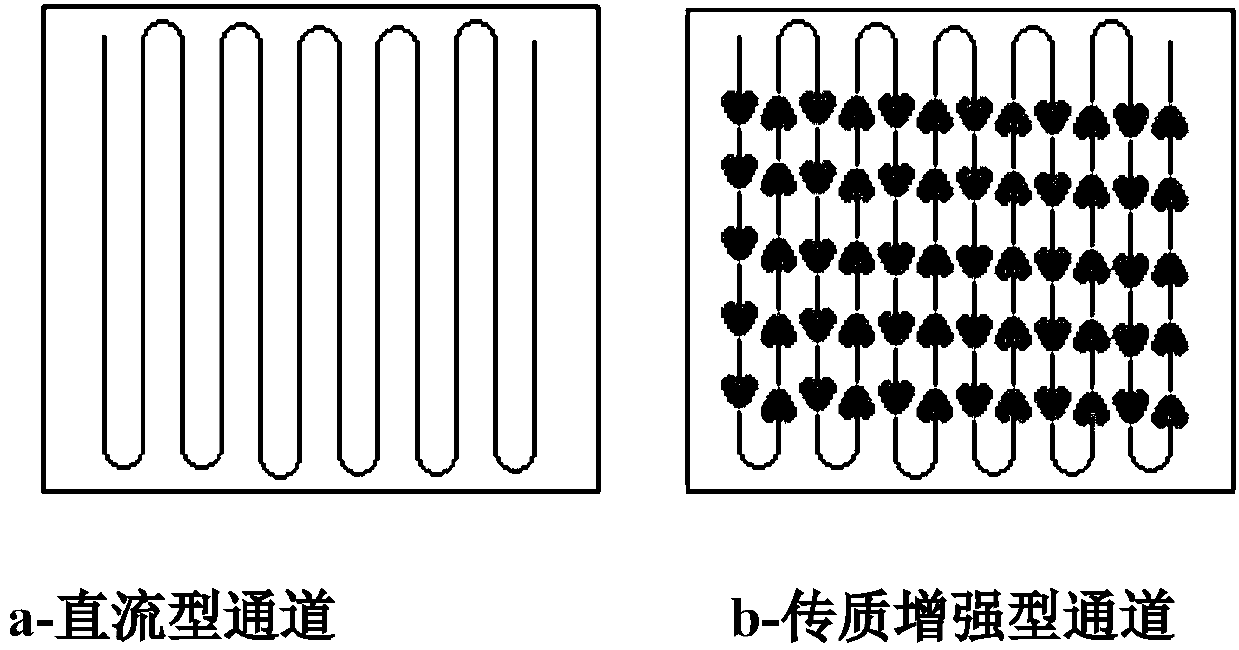

[0031] (1) Refer to figure 2 Determine the reactor connection mode, the channel type is (4e+4a) cylindrical straight channel and diamond microchannel structure, the channel volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0032] 365g (5mol) diethylamine and 1333g aqueous sodium hydroxide solution (15%) are mixed and stirred to form a diethylamine-sodium hydroxide system; m-toluoyl chloride is an acid chloride system, and the two systems are respectively mixed at 30ml / min and The flow velocity of 50ml / min is injected in the reactor by metering pump, and this moment n (m-toluoyl chloride):n (diethylamine)=1:1, adopts figure 2 In a microchannel reactor, the temperature is controlled at 30°C, the residence time is 60s, the reaction liquid is quantitatively collected and separated into a separatory funnel, the organic phase is retained, the aqueous phase is extracted three times with ether, the organic phases are combin...

Embodiment 2

[0034] (1) Refer to figure 2 Determine the reactor connection mode, the channel type is (4e+4b) cylindrical straight channel and heart-shaped microchannel structure, the channel volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0035] 365g (5mol) diethylamine and 1000g sodium hydroxide aqueous solution (20%) are mixed and stirred to form a diethylamine-sodium hydroxide system; m-toluoyl chloride is an acid chloride system, and the two systems are respectively mixed at 35ml / min and The flow rate of 45ml / min is injected in the reactor by metering pump, and this moment n (m-toluoyl chloride):n (diethylamine)=1:1.2, adopts figure 2 In a microchannel reactor, control the temperature at 35°C and the residence time of 120s. Quantitatively collect the reaction liquid into a separatory funnel for separation, keep the organic phase, extract the water phase with ether three times, combine the organic phases, dry with anhydrous s...

Embodiment 3

[0037] (1) Refer to figure 2 Determine the reactor connection mode, the channel type is (4e+4c) cylindrical straight channel and triangular microchannel structure, the channel volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0038] 365g (5mol) diethylamine and 800g aqueous sodium hydroxide solution (25%) are mixed and stirred to form a diethylamine-sodium hydroxide system; m-toluoyl chloride is an acid chloride system, and the two systems are respectively mixed at 40ml / min and The flow velocity of 40ml / min is injected in the reactor by metering pump, and this moment n (m-toluoyl chloride):n (diethylamine)=1:2, adopts figure 2 In a microchannel reactor, the temperature is controlled at 40°C, and the residence time is 180s. Quantitatively collect the reaction liquid and transfer it to a separatory funnel for separation. Keep the organic phase, extract the water phase with ether three times, combine the organic phases...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap