Method for detecting flow velocity of concrete additive compatible mortar

A concrete admixture and flow rate detection technology, which is applied in the field of concrete, can solve the problems of flow effect, setting time, slump area that cannot meet modern buildings, and property incompatibility, and achieve the effect of shortening verification time and accurate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

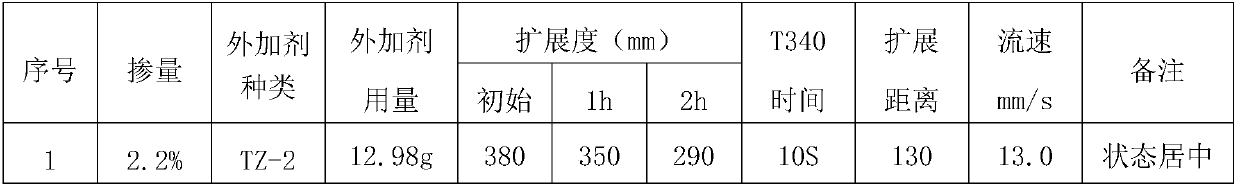

Embodiment 1

[0018] Equipment preparation: 1 set of cement mortar mixer, which meets the requirements of JC / T681; several expansion cylinders, Tube, 684ml; several glass plates, side length 550mm; 1 stopwatch, graduation value 0.1s.

[0019] Pretreatment: Wipe the inner wall of the mixing pot, mixing blade, expansion cylinder and glass plate of the cement mortar mixer evenly with a damp cloth to make the surface moist; place the glass plate horizontally, place the expansion cylinder in the center of the glass plate, and wipe it with a damp cloth Overwrite spare. A damp cloth is standard without dripping water.

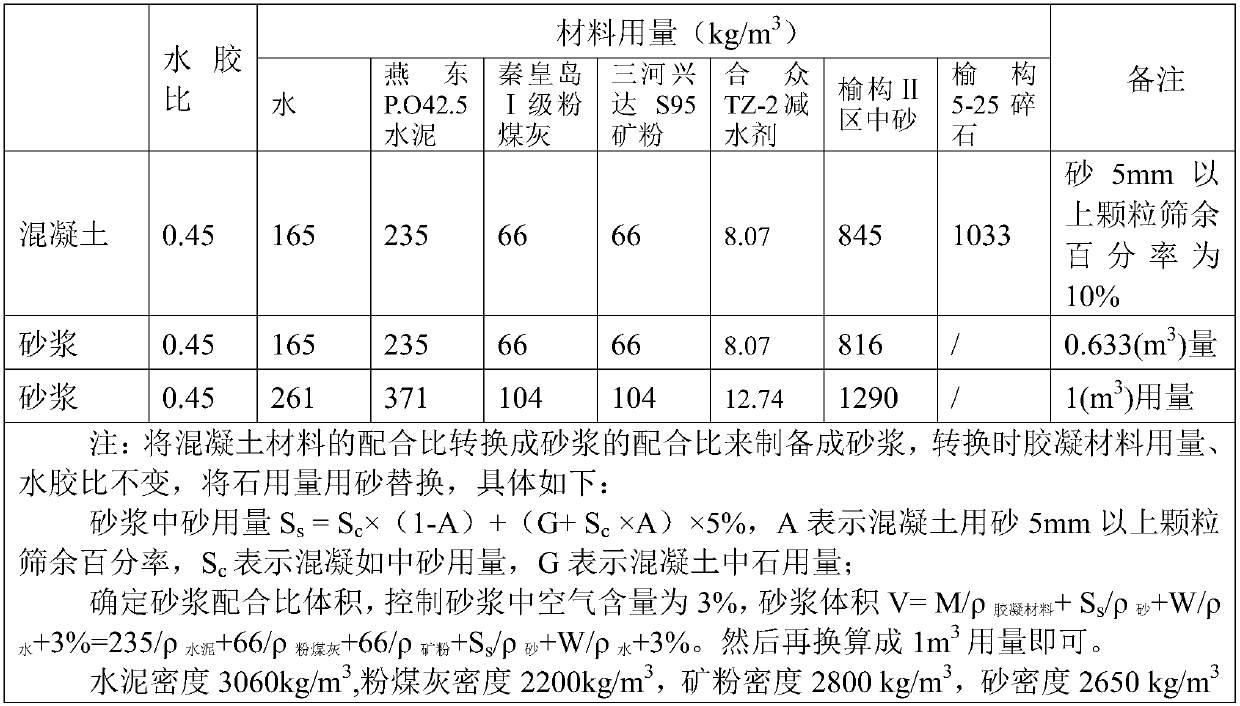

[0020] Preparation of mortar with admixture: Add the weighed cementitious material and sand into the stirring pot (that is, put the raw material components of the mortar in the stirring pot), stir for 10 seconds, and add the water mixed with the admixture evenly into the mixing pot. In the stirring pot, add time ≤ 5s, stir evenly, during the stirring process, lift the stirring p...

Embodiment 2

[0034] Equipment preparation: 1 set of cement mortar mixer, which meets the requirements of JC / T681; several expansion cylinders, Tube, 684ml; several glass plates, side length 550mm; 1 stopwatch, graduation value 0.1s.

[0035] Pretreatment: Wipe the inner wall of the mixing pot, mixing blade, expansion cylinder and glass plate of the cement mortar mixer evenly with a damp cloth to make the surface moist; place the glass plate horizontally, place the expansion cylinder in the center of the glass plate, and wipe it with a damp cloth Overwrite spare. A damp cloth is standard without dripping water.

[0036] Preparation of mortar with admixture: Add the weighed cementitious material and sand into the stirring pot (that is, put the raw material components of the mortar in the stirring pot), stir for 10 seconds, and add the water mixed with the admixture evenly into the mixing pot. In the stirring pot, the adding time is 3s, stir evenly, during the stirring process, lift the st...

Embodiment 3

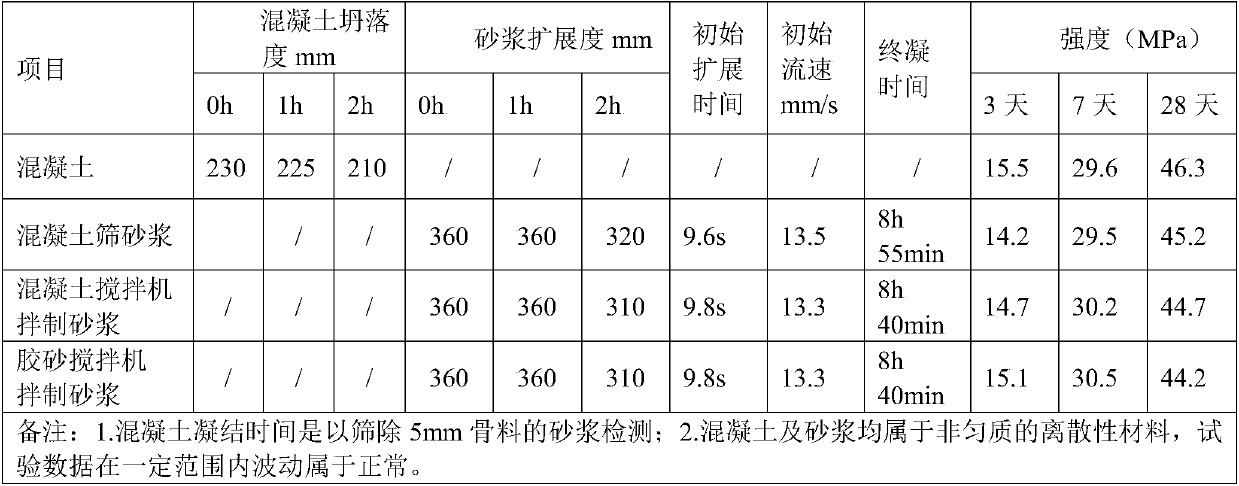

[0051] With the same method as above-mentioned Example 2, but the type and dosage of admixture are different, the time for measuring the T340 time is 16s, and the flow rate=(340-80)÷2÷16=8.125mm / s<10mm / s, which shows that it is not conducive to construction During pouring and pumping construction, the pumping resistance is relatively large, and pipe blockage is prone to occur. verified with concrete tests,

[0052] 1. Carry out the slump test of the above-mentioned concrete: put the concrete into the standard conical slump cylinder according to the prescribed method, after it is filled and leveled, lift the cylinder vertically upwards and move it aside, the concrete will slump due to its own weight, and the concrete will slump. The flow is slow, the slurry is thicker, and the thixotropy is poor.

[0053] 2. Take the concrete prepared above and carry out mechanical vibration. It is found that under the action of mechanical vibration, the flow is slow, indicating that the fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com