Method for welding zinc plated steel plate

A technology of galvanized steel sheet and welding method, which is applied in welding equipment, welding/welding/cutting articles, arc welding equipment, etc., to achieve the effect of improving coating and porosity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

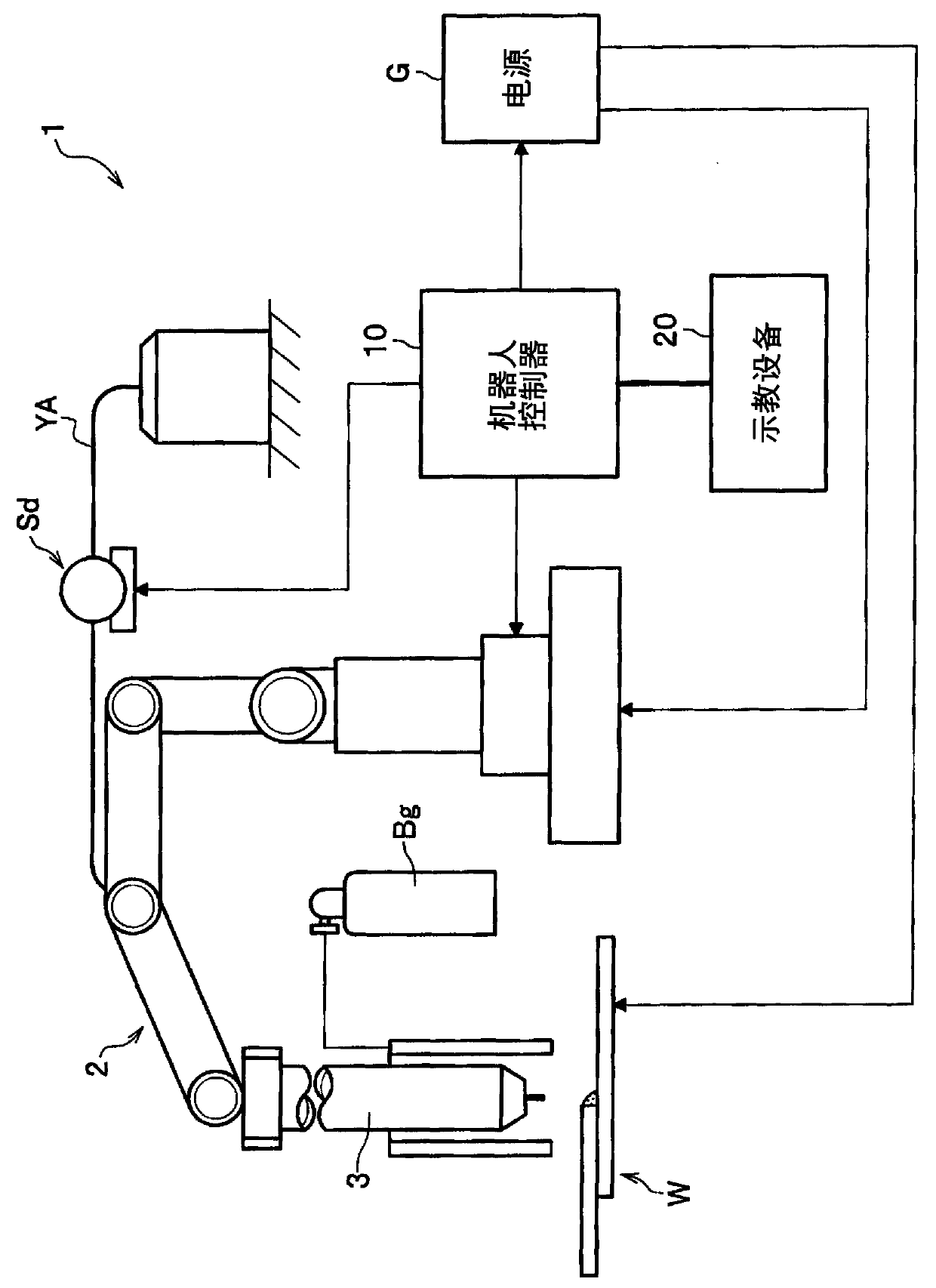

[0040] Hereinafter, a procedure for welding a galvanized steel sheet (hereinafter referred to as a welding method) according to the present invention will be described with reference to the drawings using the pulse welding device 1 . In addition, in the drawings, the plate thickness, the size and shape of the welding wire or the welding torch, the distance between members, and the like are sometimes exaggerated and schematically described for ease of understanding.

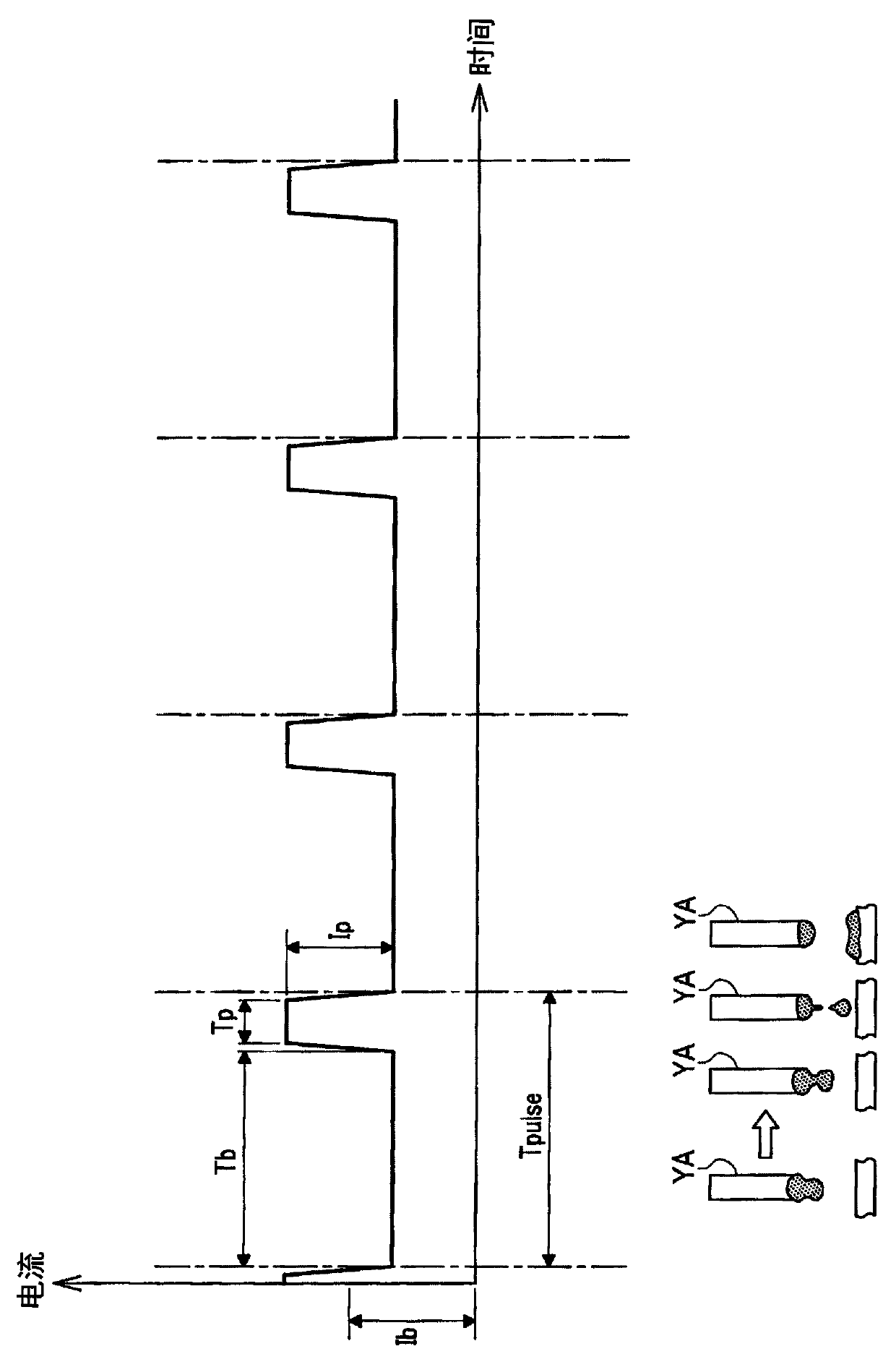

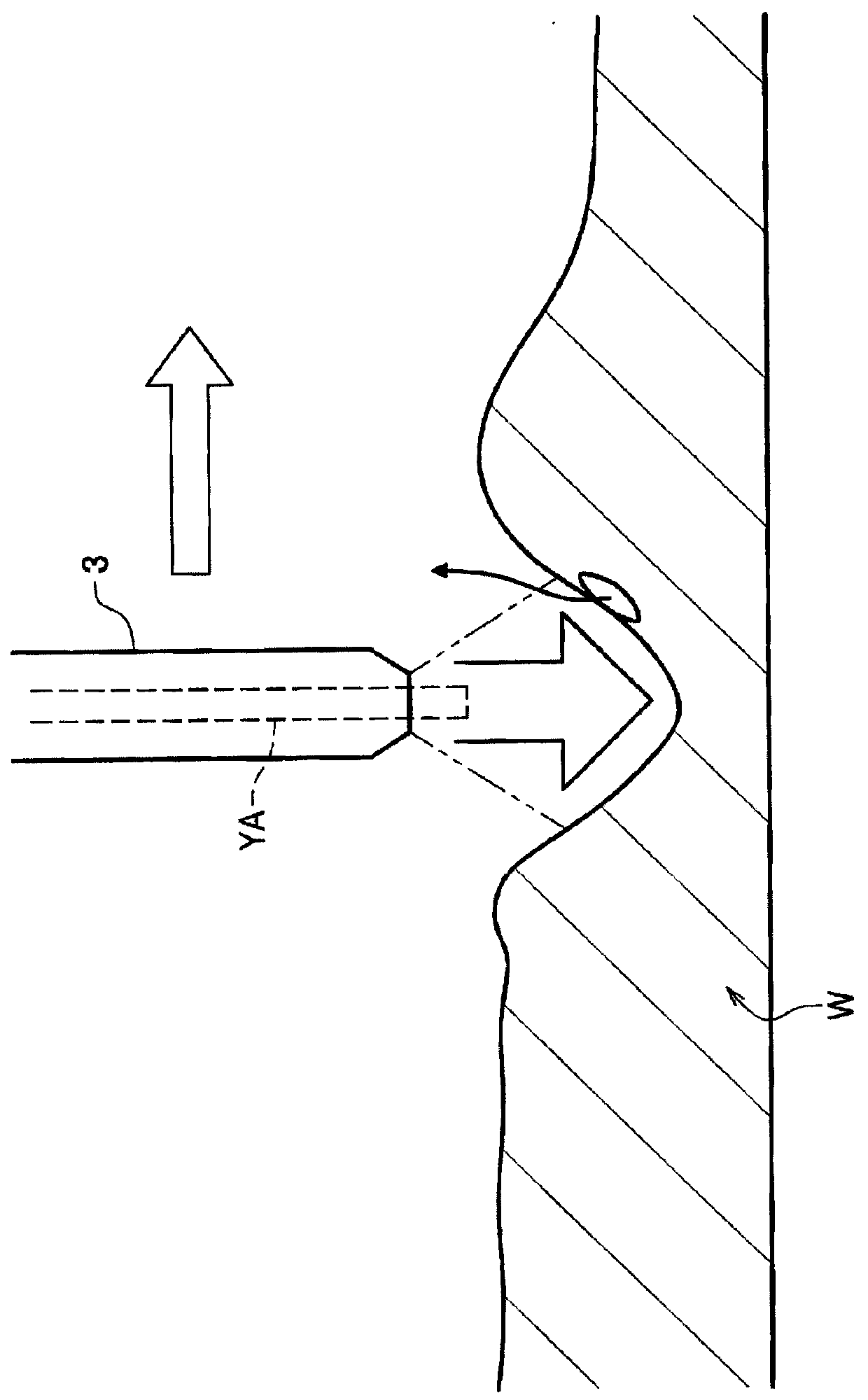

[0041] In this welding method, the welding device 1 is used, the pulse peak time is set according to the thickness of the galvanized steel sheet W, and pulse welding is performed using a welding wire and shielding gas. Here, solid wire YA is used as the welding wire, and Ar mixed gas (Ar-CO 2 Gas, Ar-O 2 Gas, Ar-CO 2 -O 2 Gas) is a shielding gas, and welding is performed by supplying a welding current, that is, a pulse current, to the solid welding wire to generate an arc between the solid welding wire YA and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com