Chassis with linear and swiveling movements

A walking mechanism and linear motion technology, applied in the field of walking mechanism, can solve the problems of inflexible use, achieve the effect of reducing weight, reducing bumps, and improving continuous or smooth movement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

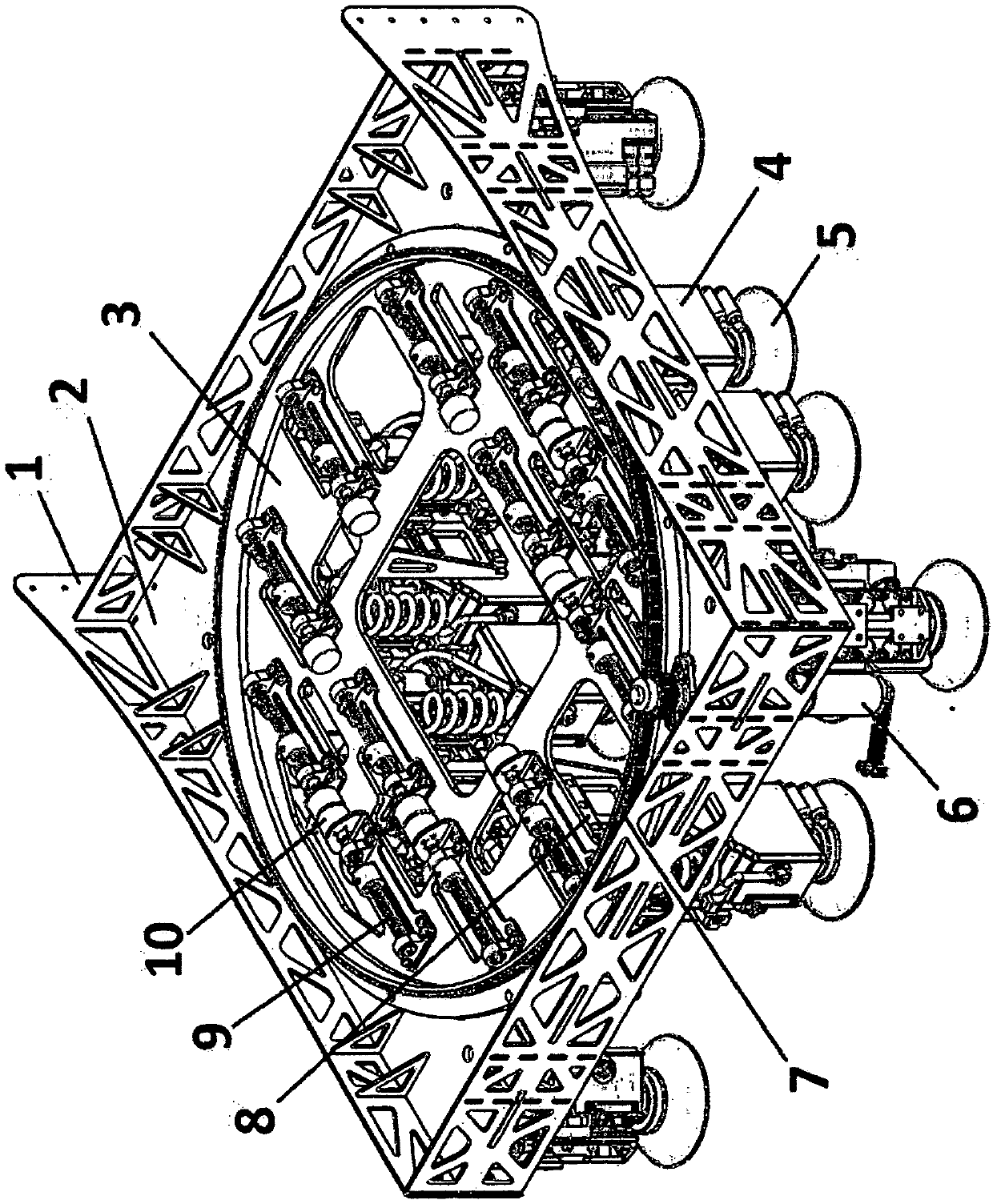

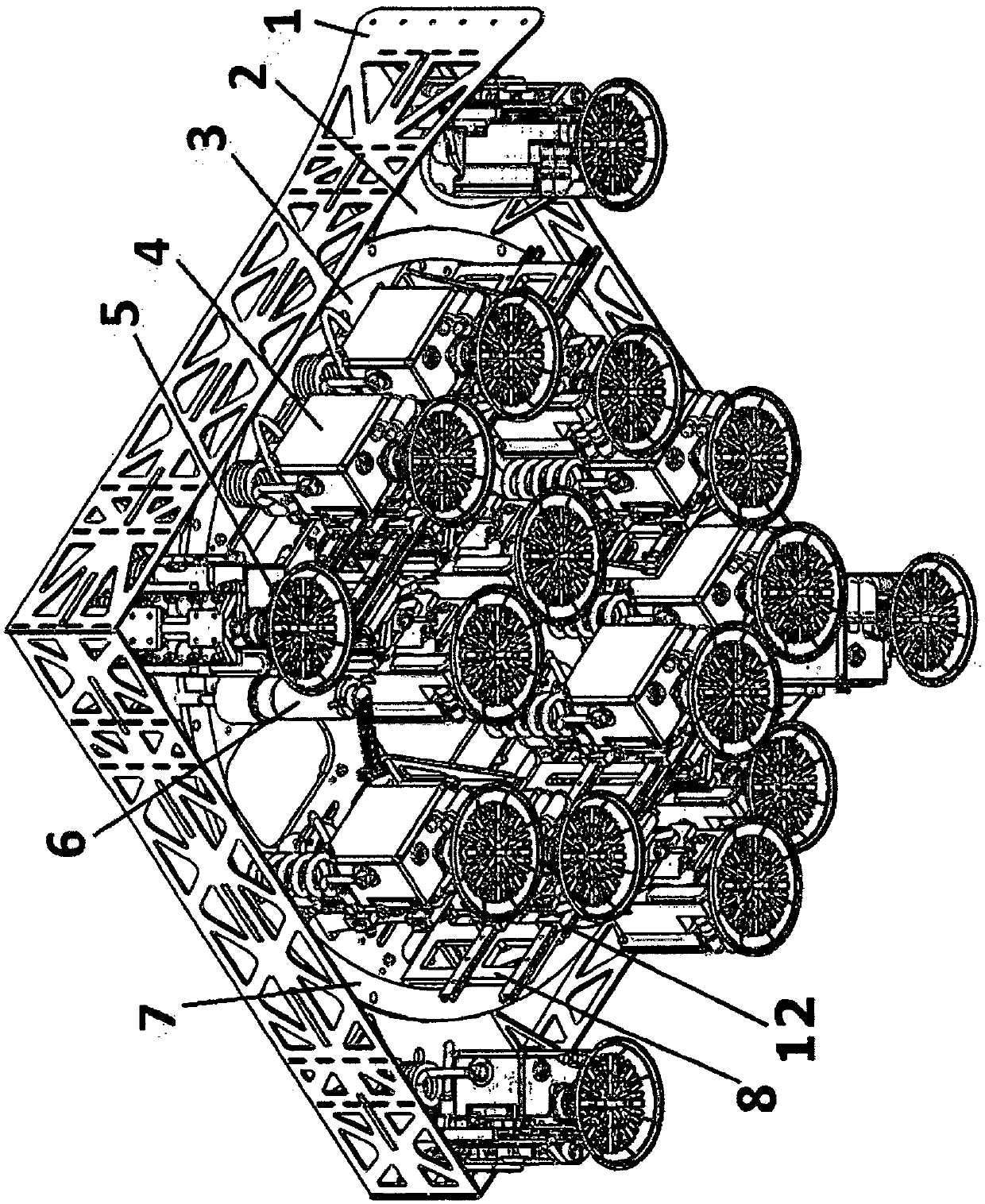

[0040] according to figure 1 as well as Figure 10 The robot shown is suitable, for example, for cleaning glass facades or other fixed, smooth, curved surfaces of buildings. For this purpose, its chassis 1 can have cleaning instruments, inspection cameras or remotely controllable manipulators for maintenance and repair tasks.

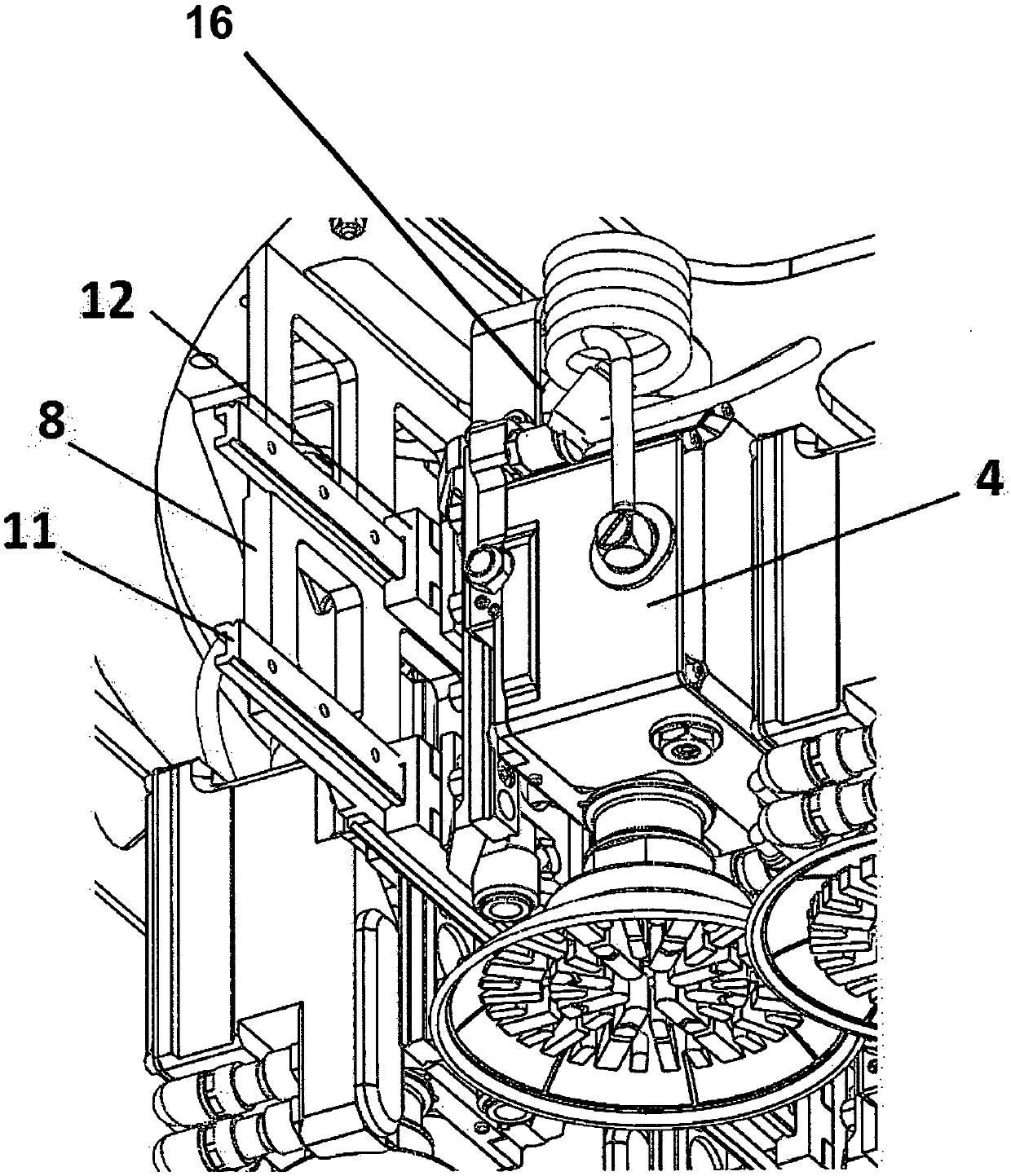

[0041] In a specific embodiment, two base plates 2 , 3 are arranged parallel to the running surface of the robot in the chassis 1 , which are rotationally moved by a gear wheel 7 operated by an electric motor 6 and can thereby be moved relative to each other. deflected movement. In this specific example, the outer base plate 2 is directly connected to the chassis 1 . In the corners of the outer base plate 2 , in the specific exemplary embodiment, the attachment module 4 with the lifting drive 16 is fastened. The attachment feet 5 fastened to the attachment module 4 always point towards the driving surface.

[0042] On the inner base plate 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com