Suction filter and fuel supply device

一种吸滤器、燃料的技术,应用在液体燃料给料机、固定式滤芯过滤器、过滤分离等方向,能够解决性能稳定性下降、吐出性能变动、堵塞网眼等问题,达到抑制稳定性下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

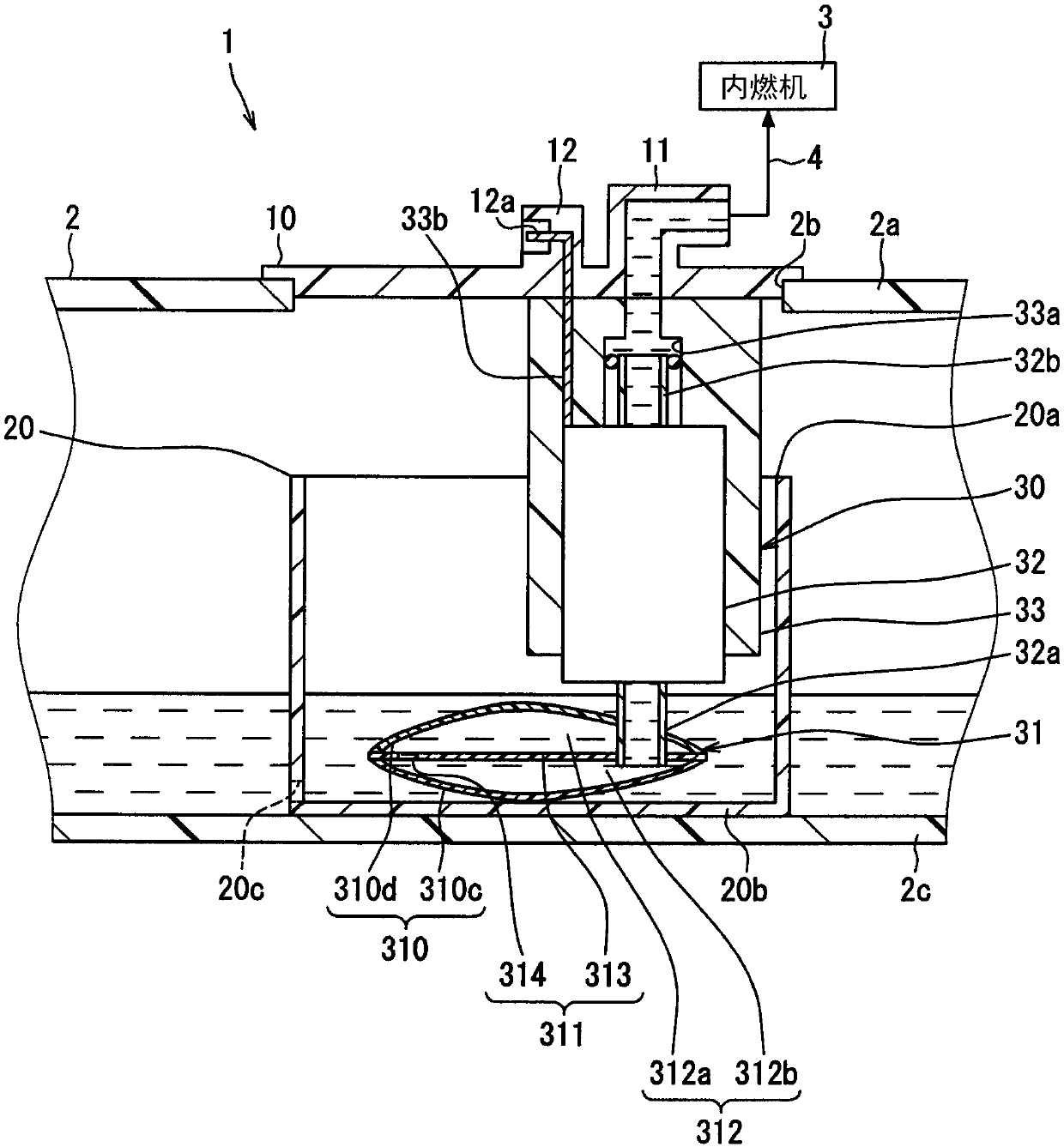

[0040] Such as figure 1 As shown, the fuel supply device 1 of the first embodiment of the present invention is mounted on a fuel tank 2 of a vehicle. The device 1 supplies the fuel in the fuel tank 2 to the internal combustion engine 3 outside the tank 2. Here, the fuel tank 2 of the mounting device 1 is formed into a hollow shape from resin, and stores the fuel supplied to the internal combustion engine 3 side. In addition, the internal combustion engine 3 supplied with fuel from the device 1 may be a gasoline engine or a diesel engine. In addition, in a vehicle on a horizontal plane, the horizontal direction and the vertical direction are respectively figure 1 The horizontal and vertical directions in are substantially the same.

[0041] (the whole frame)

[0042] First, the overall structure of the device 1 will be described.

[0043] The device 1 includes a flange 10, a sub tank 20 and a pump unit 30.

[0044] The flange 10 is formed of hard resin in a disc shape. The flange 1...

no. 2 approach

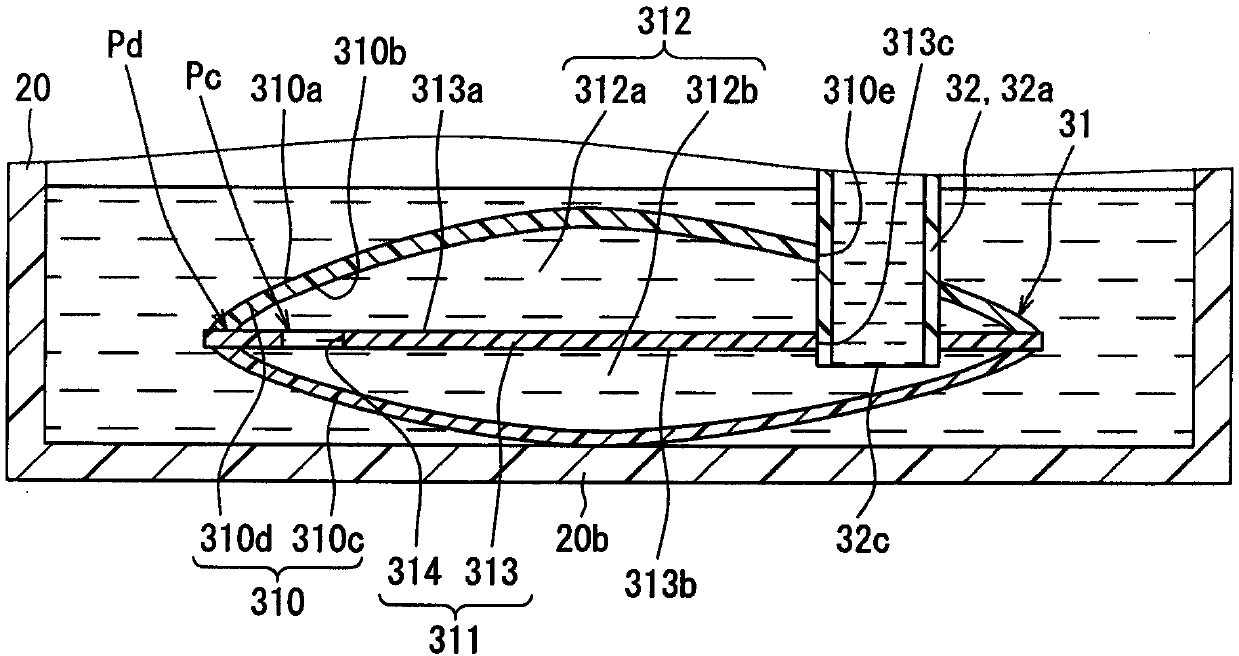

[0073] Such as Figure 4 As shown, the second embodiment of the present invention is a modification of the first embodiment.

[0074] The partition 2313 in the partition wall element 2311 of the second embodiment is joined between the outer peripheral edge portions of the respective filter sheets 310c and 310d except for a part in the circumferential direction, and is covered in a flat film shape. The partition part 2313 has a non-joining edge part 2313d in the specific site|part Pc which is not joined with respect to each filter sheet 310c, 310d. The non-joining edge portion 2313d is separated from the separation portion Pd of the joining portion of the filter pieces 310c and 310d toward the suction port 32a side of the fuel pump 32. In addition, the partition 2313 has the same structure as the first embodiment with respect to structures other than such a joining form and a separation form.

[0075] In addition, the communication window 2314 in the partition wall element 2311 of ...

no. 3 approach

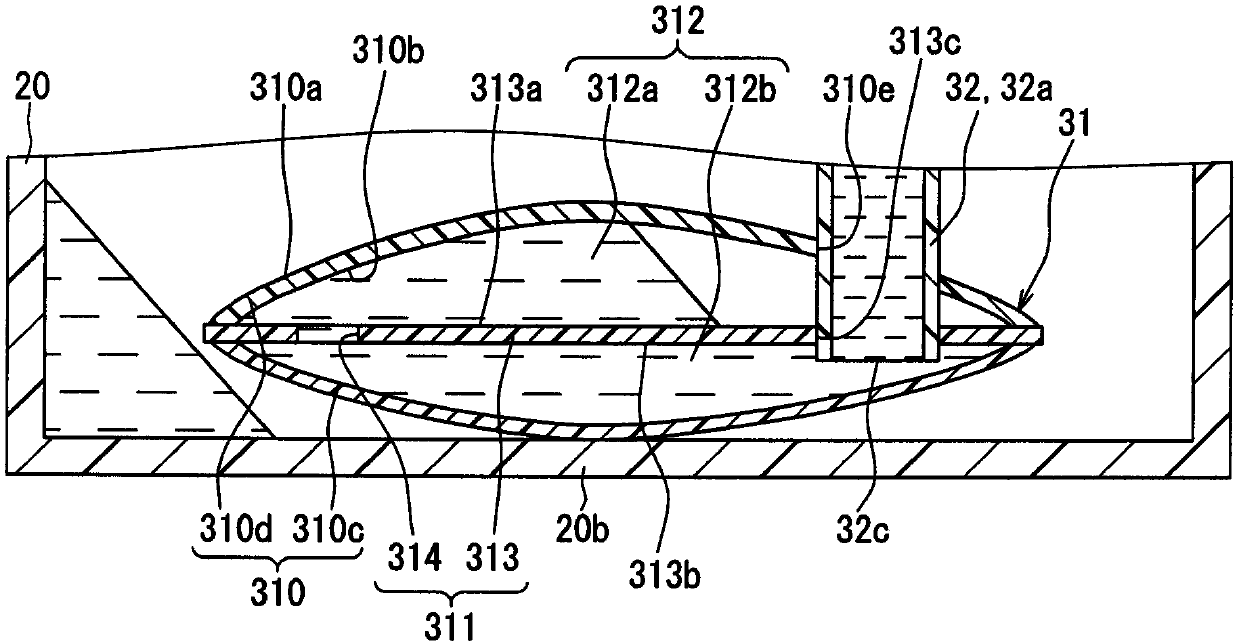

[0078] Such as Figure 5 As shown, the third embodiment of the present invention is a modification of the first embodiment.

[0079] The partition 3311 in the partition wall element 3311 of the third embodiment is entirely made of a material that performs a filtering function such as porous resin, woven fabric, non-woven fabric, resin mesh, and metal mesh, and is formed into a flexible, soft membrane. shape. The partition 3313 is joined between the outer peripheral edge portions of the filter sheets 310c and 310d over the entire circumference, and is arranged in a relaxed state in which the second space portion 312b can be expanded and contracted in a waveform. In addition, regarding structures other than such flexibility and relaxed state, the partition wall element 3311 also includes the point that it has a communication window 314, and is the same structure as the first embodiment. Therefore, a portion of the inner space 312 of the filter element 310 except for the communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com