Mechanical grabbing device for industrial robot

An industrial robot and mechanical grasping technology, applied in the field of grasping devices and mechanical grasping devices for industrial robots, can solve the problems of inflexible and rapid grasping movement of the grasping arm, low efficiency of grasping industrial products, and low degree of automation , to achieve the effect of convenient grabbing industrial products, fast moving speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

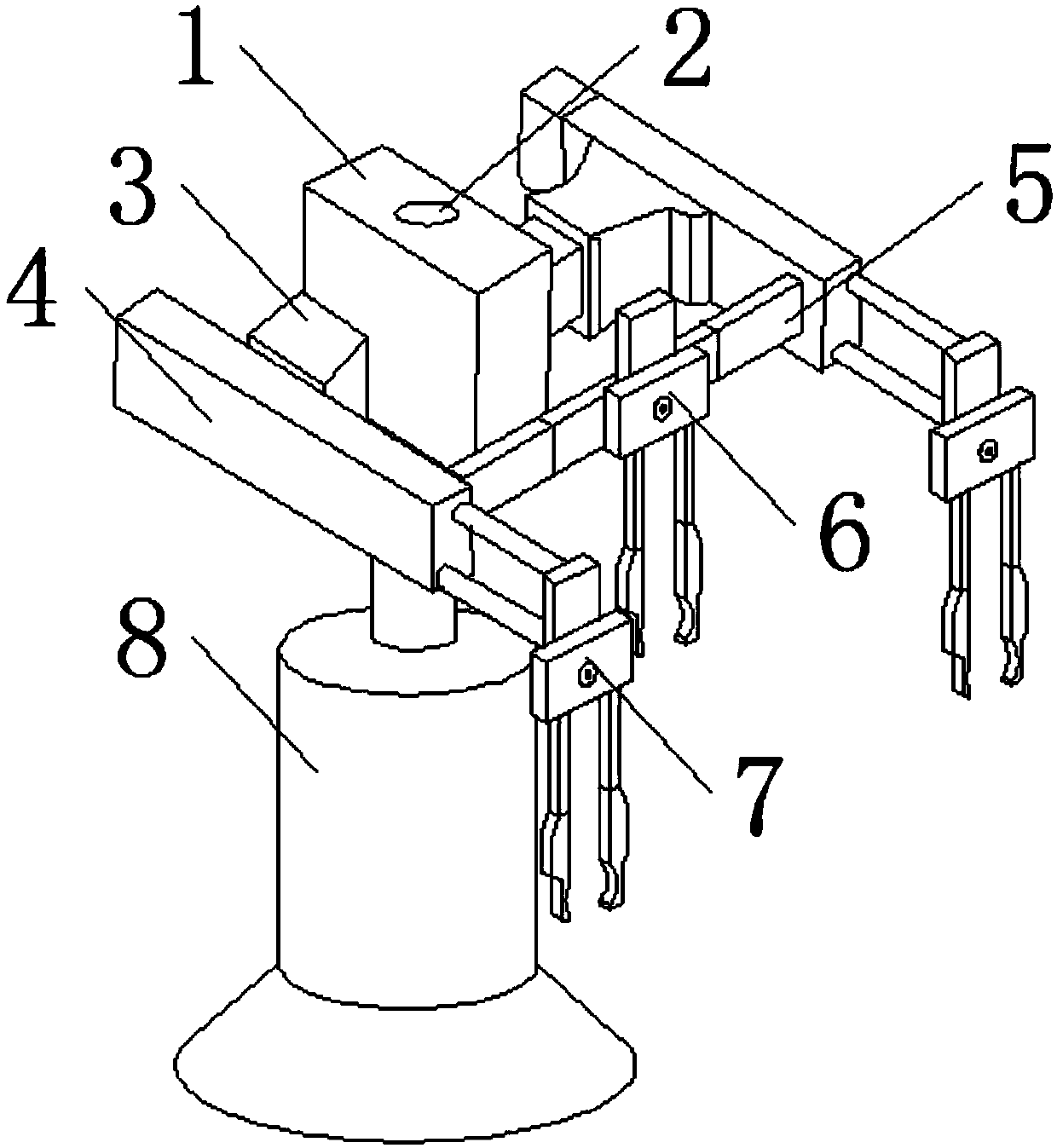

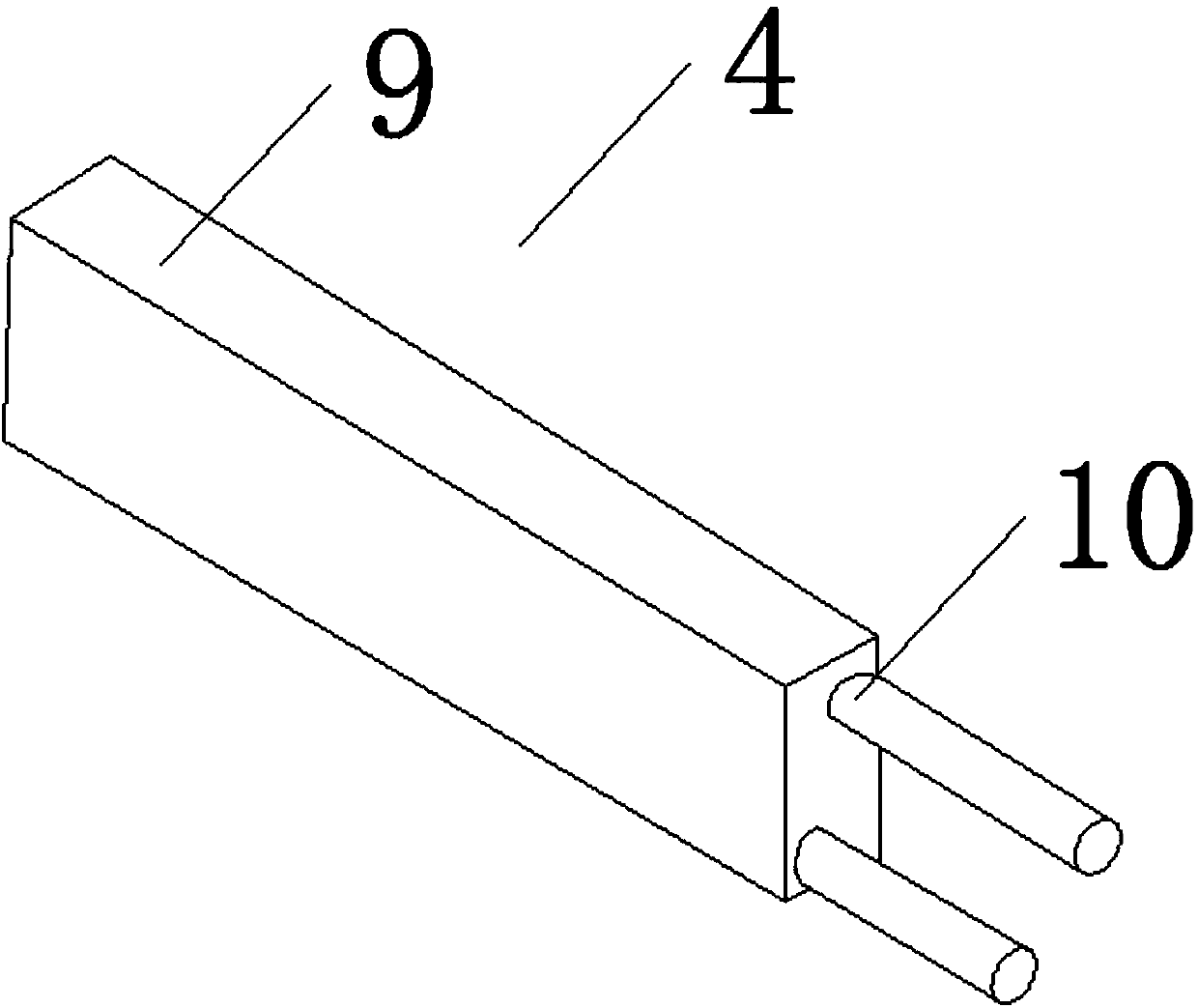

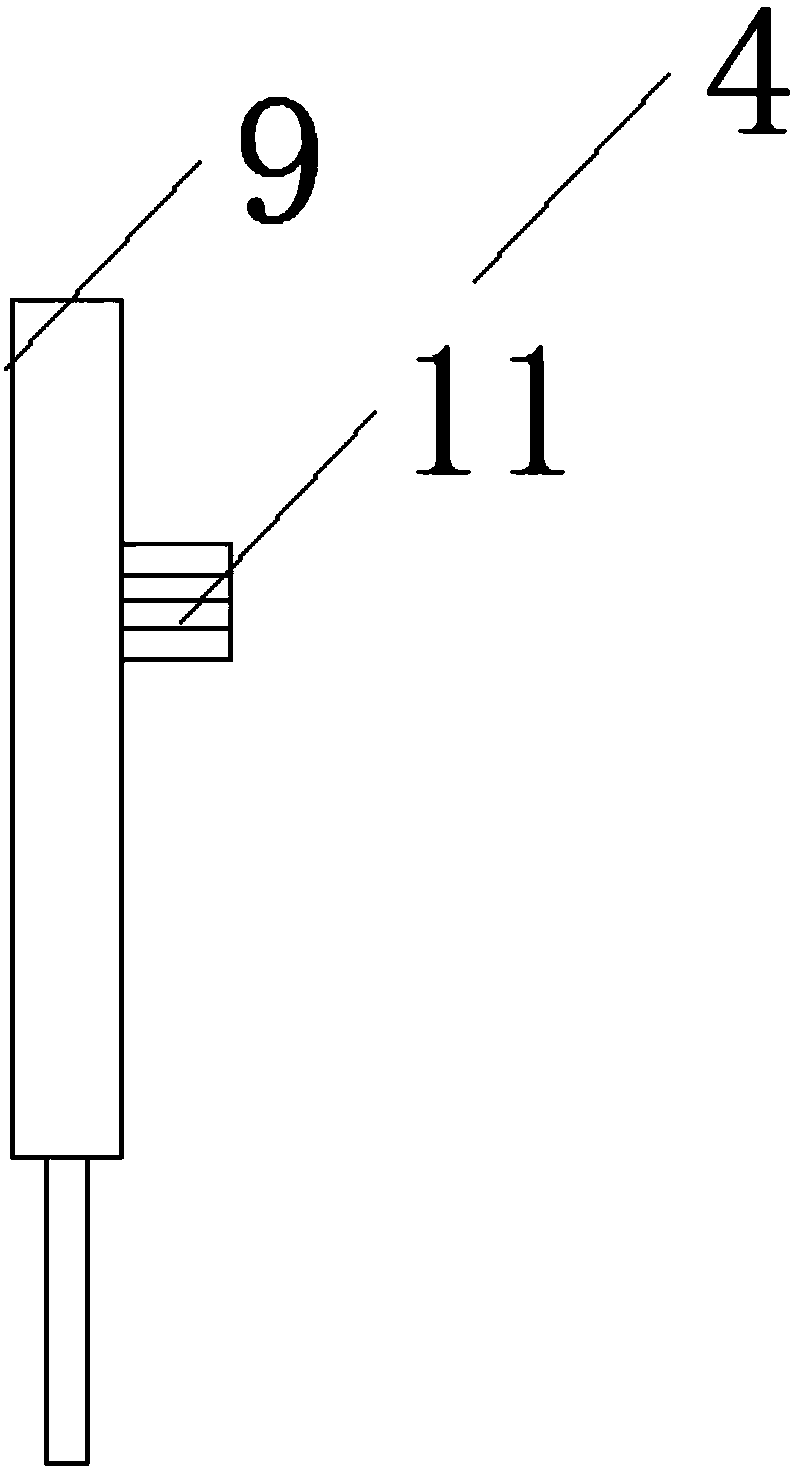

[0029] see Figure 1-8 As shown, a mechanical grabbing device for an industrial robot includes a power distribution box 1, a first hydraulic pump 4, a turning frame 6 and a grabbing plate 7. A PLC controller 2 is provided inside the power distribution box 1, and the model is C200H -The PLC controller 2 of ID212 (the manufacturer is Omron) controls the second hydraulic column 19 to move back and forth to control the grabbing arm 16 to grab and move, and the distribution box 1 is connected to the second hydraulic pump 8, the first motor 3 and the second hydraulic pump 8 through the wire 21. The motor 12 is used for power transmission, and the first motor 3 is installed at both ends of the distribution box 1, and the first hydraulic pump 4 is installed on one side of the first motor 3, and the side walls of the two first hydraulic pumps 4 are welded with hanging plates 5, and the turning frame 6 is clamped between the two hanging plates 5, and the turning frame 6 is provided with...

Embodiment 2

[0031] In addition, please continue to Figure 1-8 As shown, the difference between it and the above-described embodiment is that: the second motor 12 is provided with a second rolling gear 13 at both ends, and the second motor 12 is rotationally connected with the catch 7 through the second rolling gear 13, and the second motor 12 The grabbing plate 7 is driven to swing up and down by the second rolling gear 13 to grab industrial products. The two grasping arms 16 are arranged symmetrically, and a circular arc-shaped grasping foot 17 is arranged under the grasping arm 16. When the grasping arm 16 grasps an object, the grasping foot blocks the product, so that the movement of the device grasping the product is more stable reliable. A camera 18 is installed in the middle of the working chamber 15, and the catcher 7 recognizes the product position by the camera 18 in the working chamber 15, and the two ends of the camera 18 are provided with a second hydraulic column 19 that fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com