Vegetation concrete surface sealer and method for surface treatment of vegetation concrete

A vegetated concrete and surface treatment technology, which is applied in the field of concrete surface sealer, vegetated concrete surface sealer and surface treatment of vegetated concrete, can solve the problem of reducing the alkalinity of concrete surface, affecting the strength and durability of vegetative concrete, and affecting cement The problem of cementation with stones, etc., can achieve the effect of treatment effect, durability and moderate price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

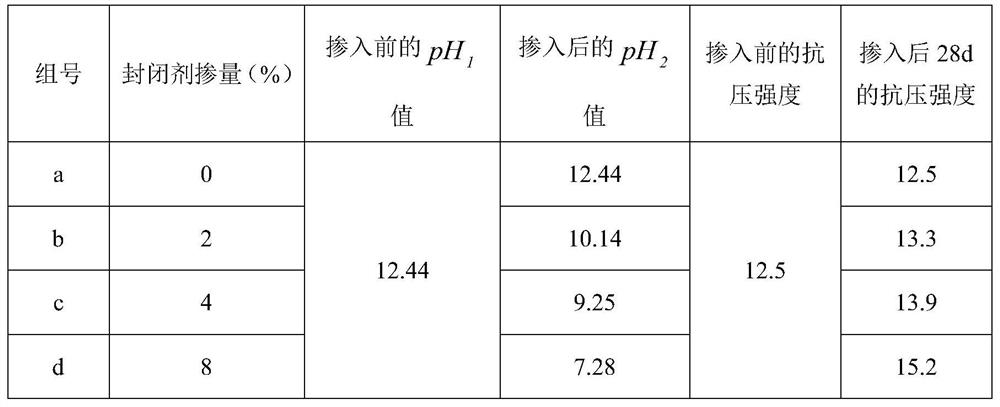

Examples

Embodiment 1

[0033]The sealing agent prepared in this embodiment includes the following components in mass percentage: 60% of acrylic emulsion; 3% of thickener; 37% of water, the viscosity of the sealing agent is 28s; the solid content of the acrylic emulsion is 35% %, when the temperature is 20°C, the viscosity is 500mPa·s; the specific gravity of the acrylic emulsion is 1.1g / cm 3 , the pH value of the acrylic emulsion is 7; the thickener is polyacrylamide.

[0034] The preparation process of the sealing agent in this embodiment is as follows: under the production condition of 25°C, add the above-mentioned water with a mass percentage of 37% to the production equipment, control the speed of the mixer at about 1000r / min, and slowly add the water with a mass percentage of 3% The polyacrylamide was stirred for about 5 minutes, the speed of the mixer was adjusted to 500r / min, and then the acrylic acid emulsion with a mass percentage of 60% was added, and the product was stirred until the prod...

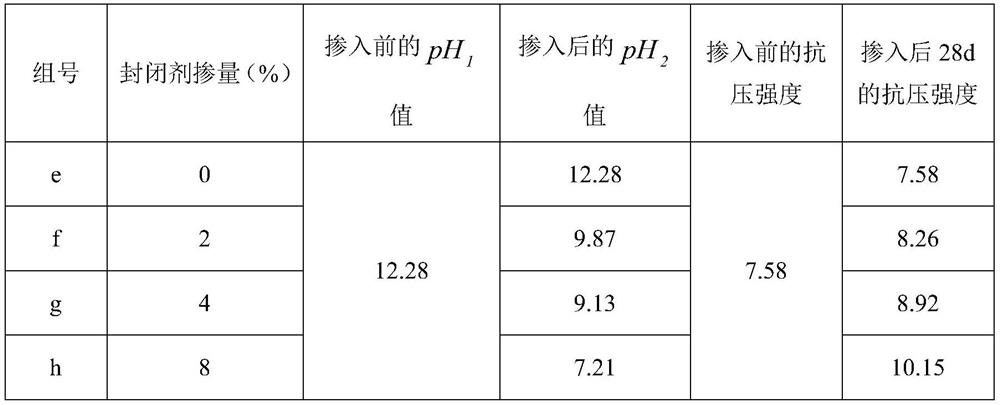

Embodiment 2

[0041] The sealing agent prepared in this embodiment includes the following components in mass percentage: 50% of acrylic emulsion; 4% of thickener; 46% of water, the viscosity of the sealing agent is 32s; the solid content of the acrylic emulsion is 36 %, when the temperature is 20°C, the viscosity is 650mPa·s; the specific gravity of the acrylic emulsion is 1.1g / cm 3 , the pH value of the acrylic emulsion is 8; the thickener is carboxymethyl cellulose.

[0042] The preparation process of the sealing agent of this embodiment is as follows: under the production condition of 25°C, add the above-mentioned water with a mass percentage of 46% into the production equipment, control the speed of the mixer at about 1000r / min, and slowly add the water with a mass percentage of 4% Carboxymethyl cellulose, stirred for about 5 minutes, adjusted the speed of the mixer to 500r / min, then added acrylic acid emulsion with a mass percentage of 50%, and stirred until the product was uniformly d...

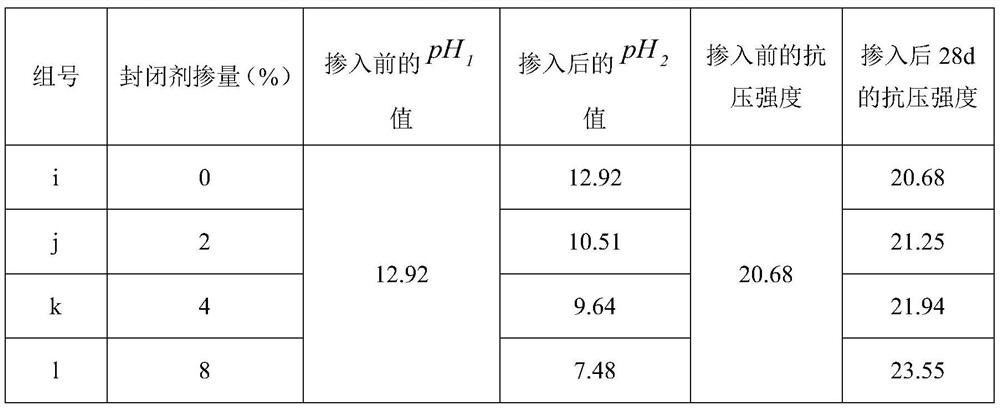

Embodiment 3

[0049] The sealing agent prepared in this embodiment includes the following components in mass percent: 55% of acrylic emulsion; 5% of thickener; 40% of water, the viscosity of the sealing agent is 35s; the solid content of the acrylic emulsion is 37 %, when the temperature is 20°C, the viscosity is 700mPa·s; the specific gravity of the acrylic emulsion is 1.1g / cm 3 , the pH value of the acrylic emulsion is 7.5; the thickener is gelatin, and the average relative molecular mass of the gelatin is 1.0×10 7 ; When the temperature is 20℃, the viscosity is 300Pa · s.

[0050] The preparation process of the sealing agent of this embodiment is as follows: under the production condition of 25°C, add the above-mentioned water with a mass percentage of 40% to the production equipment, control the rotation speed of the mixer at about 1000r / min, and slowly add 5% by mass Carboxymethyl cellulose, stirred for about 5 minutes, adjusted the speed of the mixer to 500r / min, then added acrylic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com