A method for directly recovering and reusing fracturing flowback fluid

A fracturing flowback fluid, direct technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as storage of fracturing flowback fluid and glue back without consideration, and achieve excellent sand-carrying performance, The effect of stable performance and low implementation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

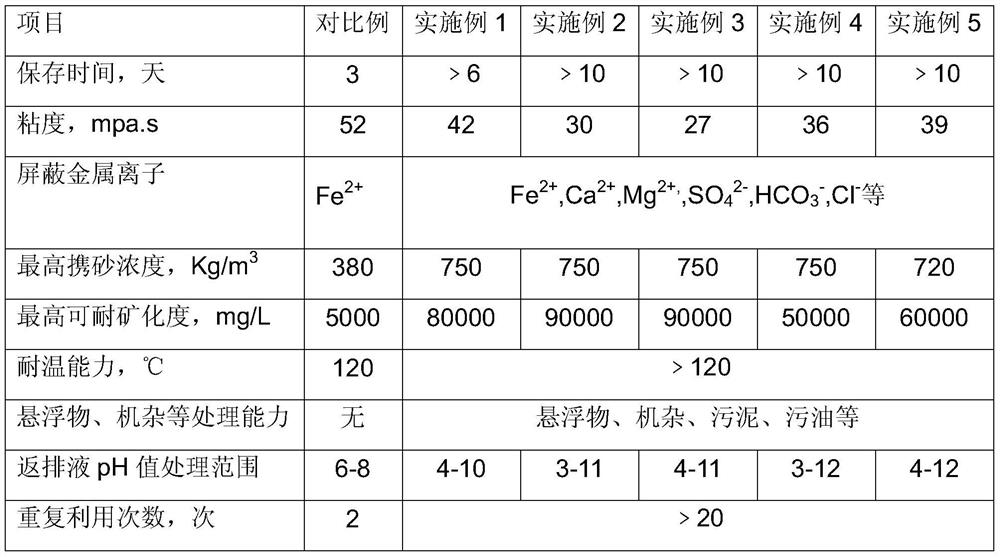

Examples

Embodiment 1

[0043] A new Triassic well (1#) reservoir has a buried depth of 1670m and a formation temperature of 51°C. After the first stage of fracturing flowback fluid is recovered on site, the sand removal tank is settled and treated, and then transferred to the liquid storage tank. During the transfer process, 0.08% alkyl dimethyl ammonium acetate fungicide is added for centralized storage for 6 days; the second stage Before fracturing, add 0.08% polyferric sulfate and 0.16% EDTA disodium before preparing fracturing fluid, use cement truck to circulate for 5 minutes, then add 0.2% citric acid, and circulate for 5 minutes; then add 0.3% hydroxypropyl guanidine in sequence according to the designed formula Glue, 0.5% perfluoroalkyl carboxylic acid drainage aid, 0.5% potassium chloride, and finally 0.8m 3 / min displacement cycle for 10min to form guar gum base liquid. During fracturing construction, add 0.3% cross-linking agent (triethanolamine borate: borax = 1:3) to form gel to carry ...

Embodiment 2

[0045] A new Triassic well (2#) has a reservoir with a depth of 2050m and a formation temperature of 70°C. After recovering the first-stage fracturing flowback fluid on site, the desander tank was settled and treated, and then transferred to the fluid storage tank. During the transfer process, the Add 1.0% potassium sorbate bacterial agent and store for 10 days; before the second stage of fracturing, add 0.05% glucose and 0.10% tetrasodium EDTA before preparing the fracturing fluid, use a cement truck to circulate for 10 minutes, then add 0.3% glucose acid, circulated for 5min; then add 0.3% carboxymethyl hydroxypropyl guanidine gum, 0.5% perfluorooctyl sulfonate tetraethylamine amide drainage aid, 0.5% polyepichlorohydrin-dimethylamine in sequence according to the designed formula, and finally Use 1.0m 3 / min displacement cycle for 5min to form the base liquid. During fracturing construction, add 0.5% cross-linking agent (ethylene glycol borate: sodium borate = 1:8) to form ...

Embodiment 3

[0047] A new Triassic well (2#) has a reservoir with a depth of 1800m and a formation temperature of 64°C. After recovering the first-stage fracturing flowback fluid on site, the desanding tank was settled, and then transferred to the fluid storage tank. During the transfer process, the Add 1.0% butylparaben fungicide and store for 10 days; before the second stage of fracturing, add 0.06% polychlorinated chlorine chloride and 0.12% EDTA before preparing the fracturing fluid, use cement truck to circulate for 8 minutes, and then add 0.2% Sodium bicarbonate, circulate for 5 minutes; then add 0.2% carboxymethyl guar gum, 0.4% perfluoropropyl alkyl sulfonate drainage aid, 0.3% polyepichlorohydrin-dimethylamine clay stabilizer according to the designed formula , and finally adopt 4.0m 3 / min displacement cycle for 15min to form the base fluid. During fracturing construction, add 0.4% cross-linking agent (ethylene glycol borate: sodium borate = 1:4) to form gel to carry proppant (q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com