Air-liquid double-vortex kinetic-energy pulping device capable of collecting rainwater and wind energy

A double scroll, wind energy technology, applied in the field of mechanical energy, can solve the problems of low efficiency of mechanical pulping, fixed rotor rotation, uneven pulping, etc., to increase sealing, capacity, stiffness and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

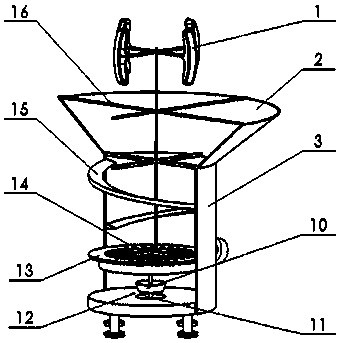

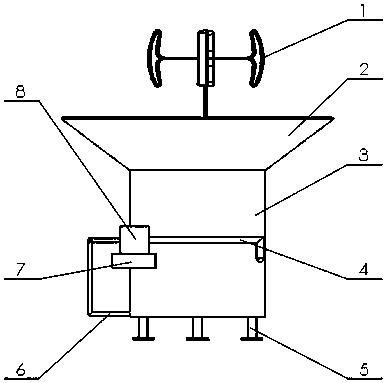

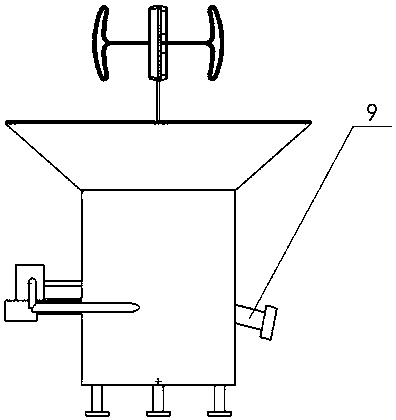

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a gas-liquid double-vortex kinetic energy pulping equipment that collects rainwater and wind energy mainly includes a rainwater collection device, a wind energy conversion device, a mechanical cleaning filter hole device, an air cleaning filter hole device, and an automatic adjustment to recover and filter water volume reverse overflow device and a gas-liquid double vortex generating device. The rainwater collection device is mainly composed of a conical reel 2 and an offset cross steel plate 16, the small end of the conical reel 2 is welded to the upper end of the barrel 3, and the large end of the conical reel 2 is welded to the offset cross steel plate 16; wind energy conversion The device is mainly composed of blades 1, trusses and transmission shafts 17. Four identical blades 1 are welded to the four trusses respectively. The crossing points of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com