Direct insertion type laser white light source

A white light source, in-line technology, applied in the direction of light source, light source fixation, semiconductor devices of light-emitting elements, etc., can solve the problems of complex process, inconvenient application, backward technology, etc., achieve high light conversion efficiency, ensure standardization, and stable light quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

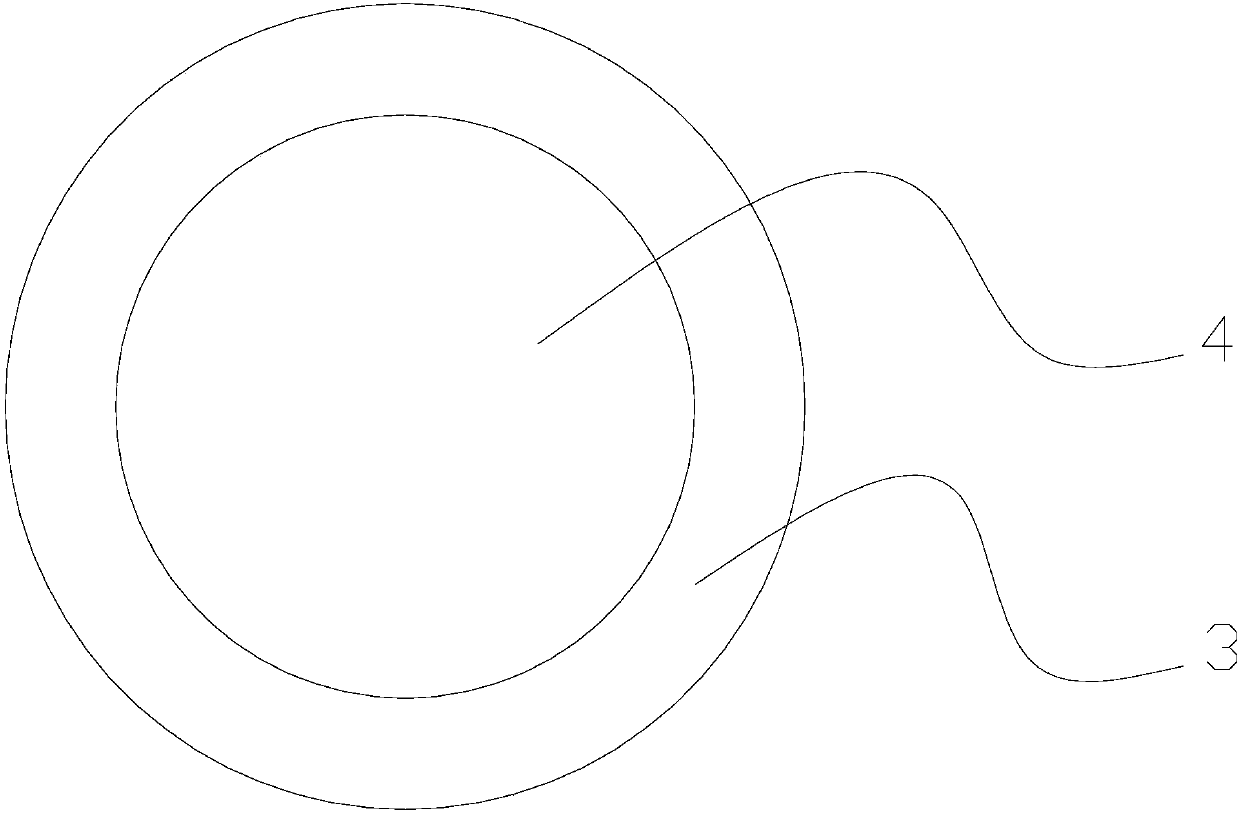

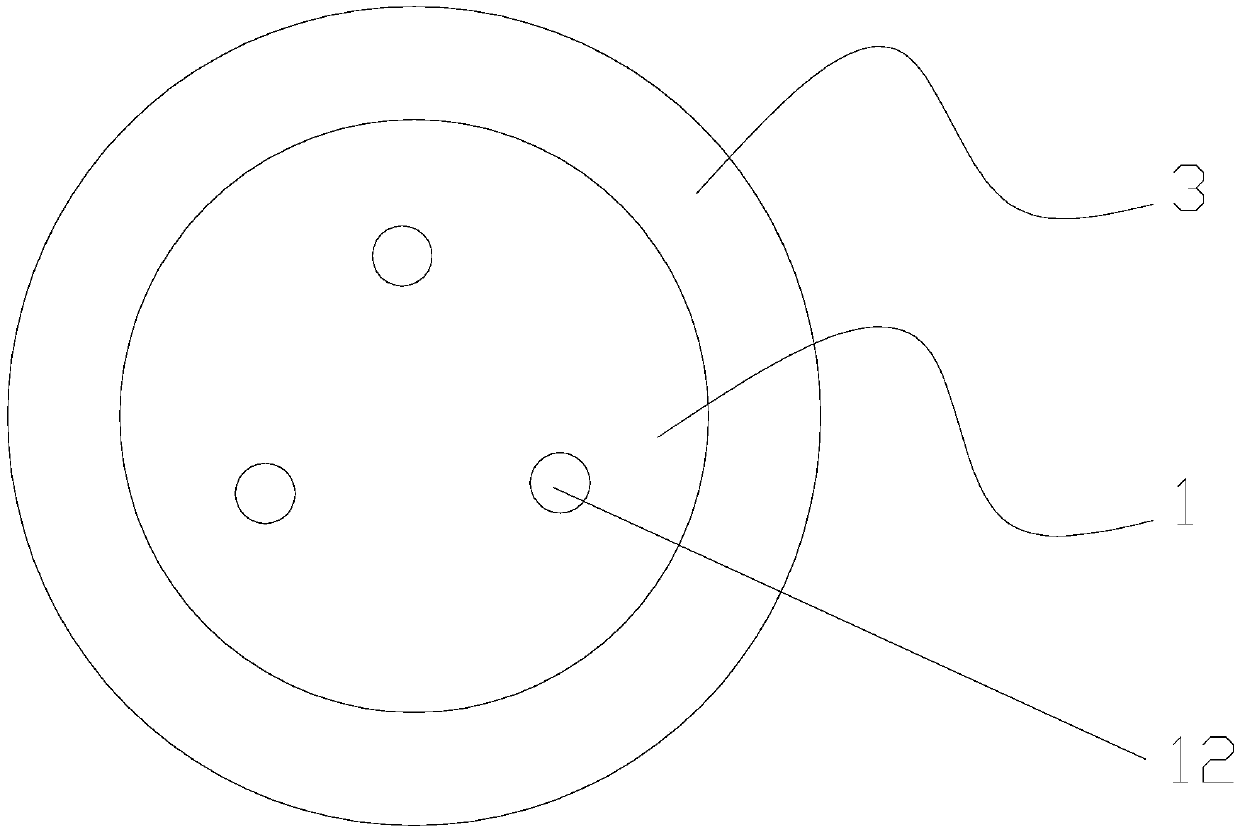

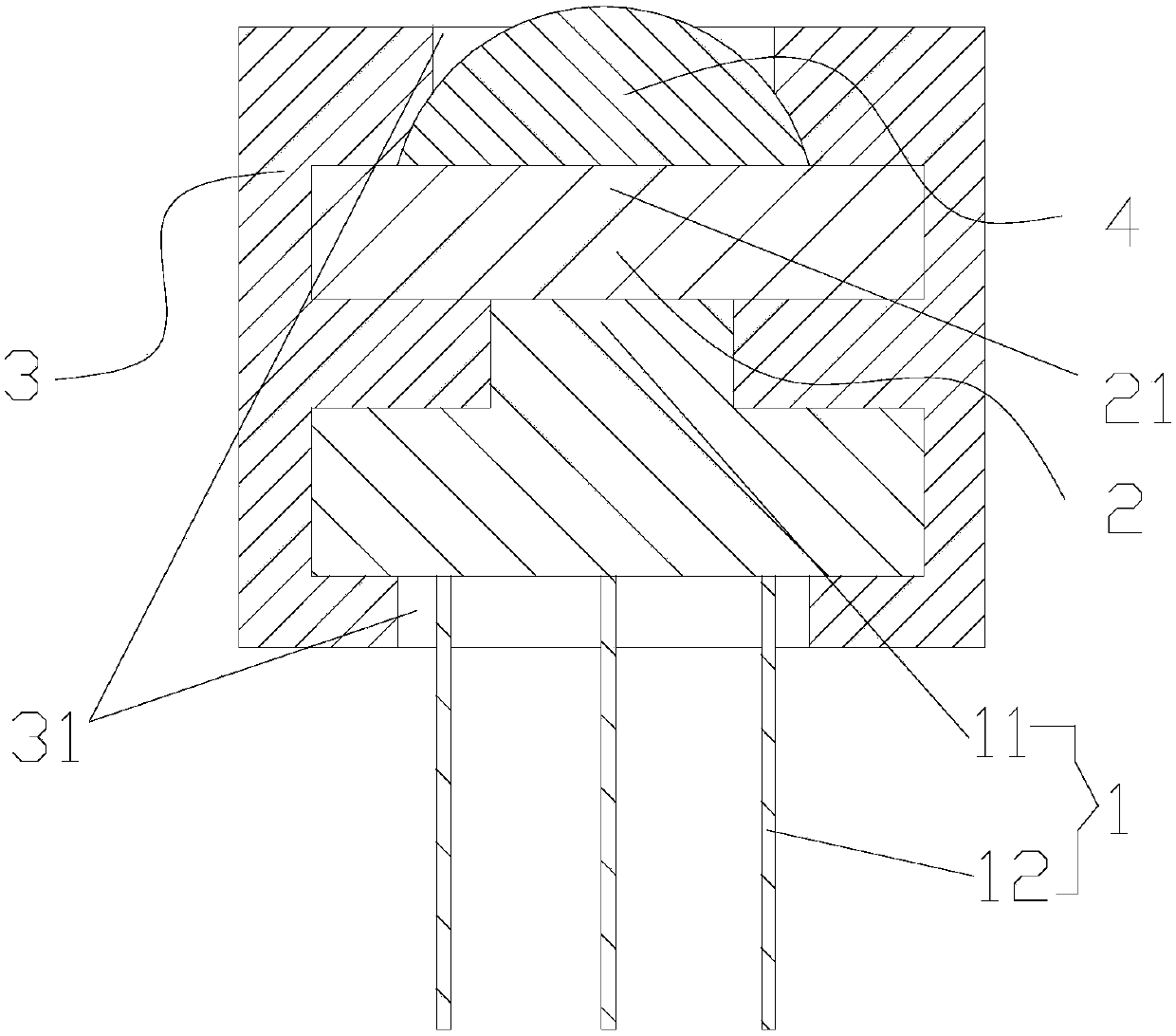

[0039] Such as Figure 1-3 As shown, an in-line laser white light source according to the present invention includes an in-line blue laser emitting device 1, a light conversion medium 2 and a fixing device 3; the upper surface of the in-line blue laser emitting device 1 is a laser The exit end 11 has a pin 12 on the lower surface; the light conversion medium 2 is fixed on the surface of the laser exit end 11 of the in-line blue-ray laser emitting device 1 through the fixing device 3; the in-line blue-ray laser emitting device 1 emits The blue laser light passes through the light conversion medium 2 and is excited and converted into white light.

[0040] The light conversion medium 2 is any one of fluorescent glass, transparent fluorescent ceramics, and fluorescent single crystal. Its body is yellow or yellow-green, and the wavelength of white light converted by it is 520-760nm.

[0041] The visible light transmittance of the light conversion medium 2 is ≥80%.

[0042] The l...

Embodiment 2

[0050] Such as figure 1 , 2 , 4, the difference between it and Embodiment 1 is that the laser emitting end 11 of the in-line blue-ray laser emitting device 1 is embedded in the light conversion medium 2 .

Embodiment 3

[0052] Such as figure 1 , 2 , 5, the difference between it and Embodiment 1 is that: the shape of the light exit surface 21 of the light conversion medium 2 is a conical surface, and the exit angle of the conical surface is 1-150°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com