Small-angle white light source

A white light source, small angle technology, applied in the field of white light source, can solve the problems of short projection distance, backward technology, complicated process, etc., to achieve the effect of short projection distance, increased intensity and projection distance, and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

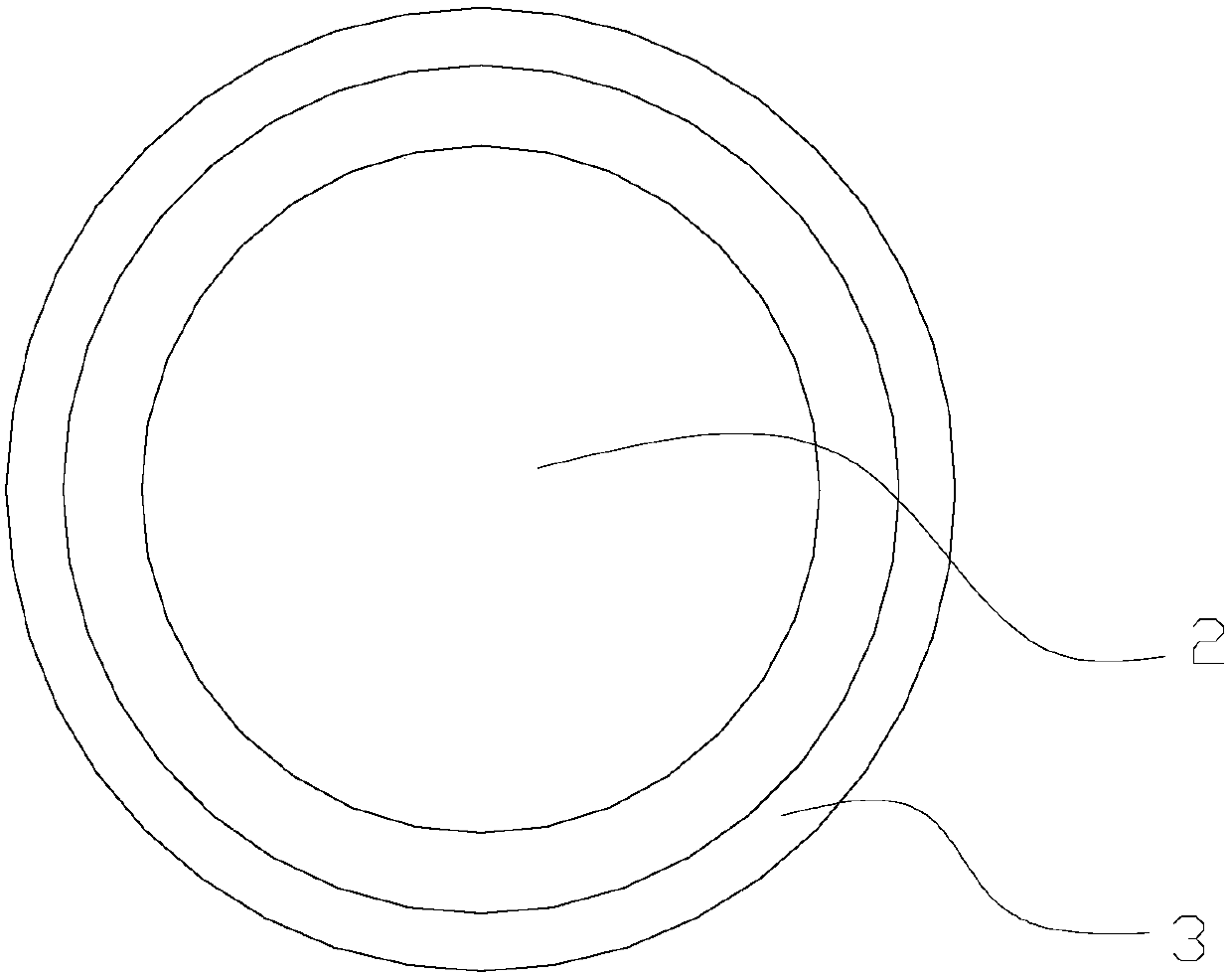

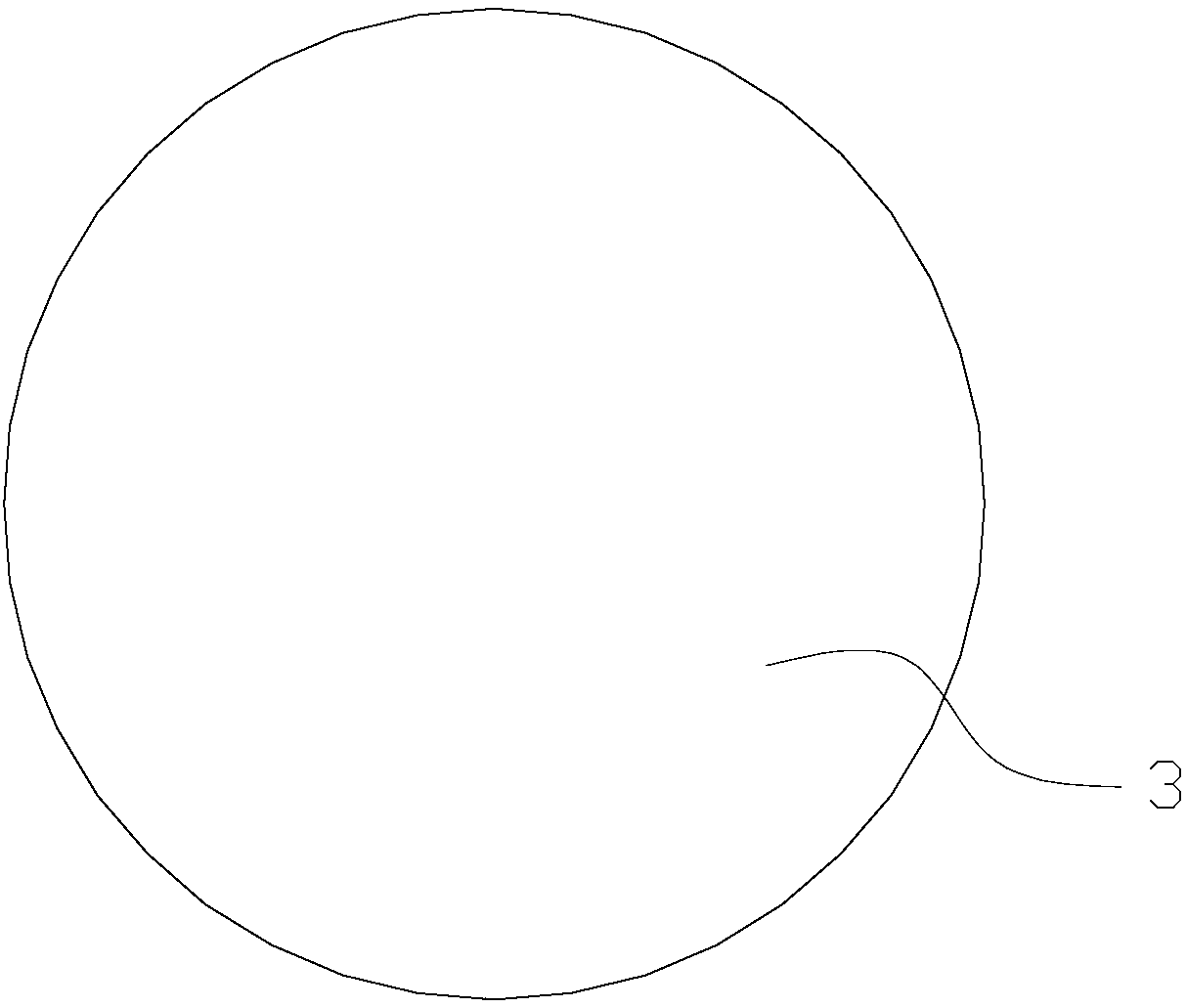

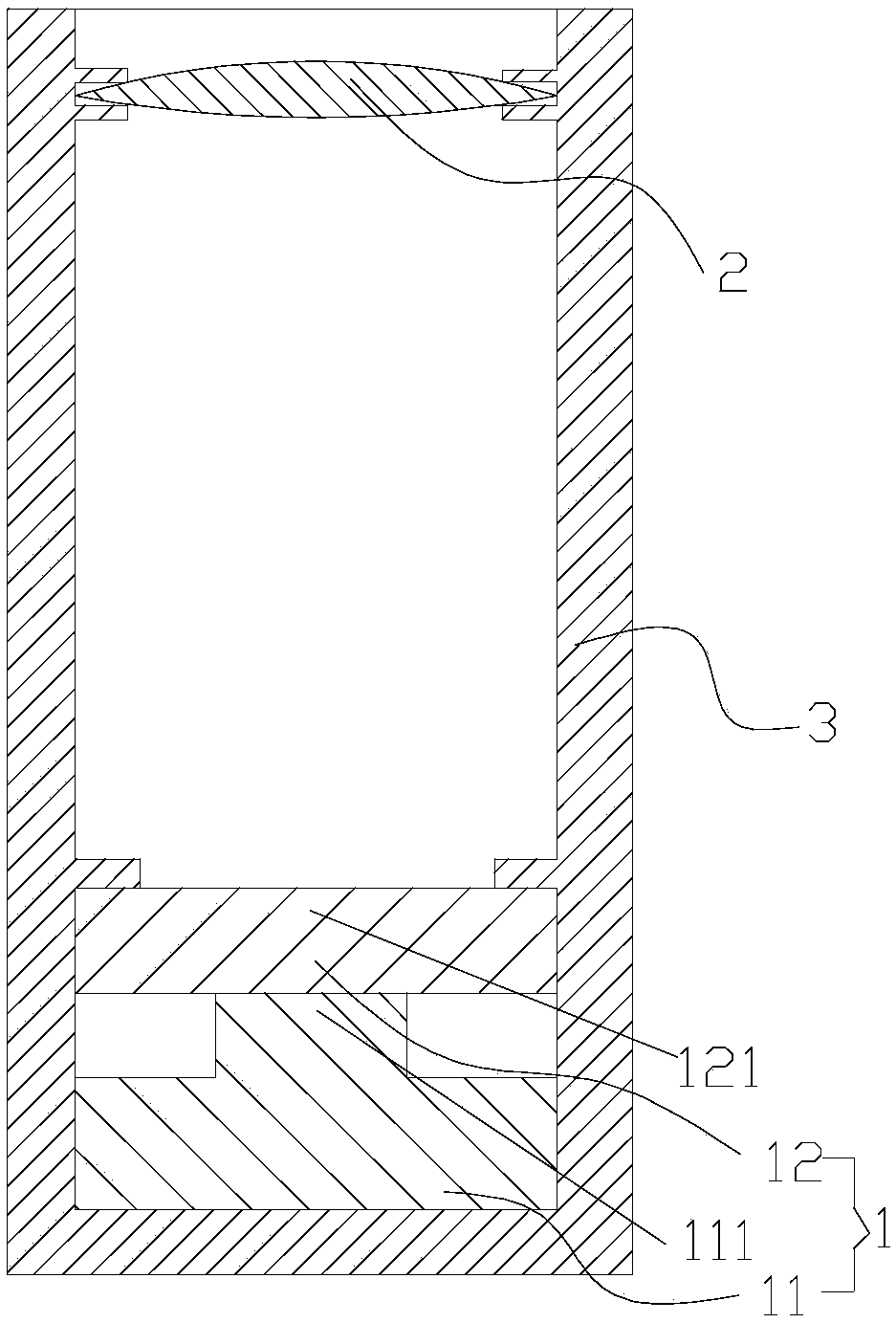

[0048] Such as Figure 1-3As shown, a small-angle white light source according to the present invention includes a laser white light source 1 and a collimator lens 2 arranged directly above the light output end of the laser white light source 1, and the laser white light source 1 includes a blue laser emitting device 11 and a light conversion medium 12, the light conversion medium 12 is arranged on the surface of the laser output end 111 of the blue laser emitting device 11; the blue laser emitted by the blue light laser emitting device 11 is excited and converted into white light after passing through the light conversion medium 12, and the white light The collimated lens 2 is collected into small-angle white light. The small-angle white light source also includes a hollow and long cylindrical cavity 3 with an open top, and the collimator lens 2 and the laser white light source 1 are respectively fixed at the upper and lower ends of the cavity 3 . The laser white light sourc...

Embodiment 2

[0050] Such as Figure 4 As shown, the difference from Embodiment 1 is that the light conversion medium 12 is fixed on the surface of the laser emitting end 111 of the blue laser emitting device 11 by the fixing device 13 . The laser emitting end 111 of the blue laser emitting device 11 is embedded in the light converting medium 12 .

Embodiment 3

[0052] Such as Figure 5-7 As shown, the difference from Embodiment 1 is that: the shape of the light exit surface 121 of the light conversion medium 12 is a conical surface, wherein the exit angle of the conical surface is 1-150°. The bottom of the cavity 3 is open, and the blue-ray laser emitting device 11 is an in-line blue-ray laser emitting device. The upper surface of the in-line blue-ray laser emitting device is a laser emitting end 111, and a pin 112 is provided on the lower surface. The pin 112 protrudes from the opening at the bottom of the cavity 3 . The in-line blue-ray laser emission device is a blue-ray laser light source packaged in TO form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com