Full-size textured drill sliding bearing experimental device and test method

A technology of sliding bearings and experimental devices, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of unclear mechanism, difficult service life of roller cone bit sliding bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

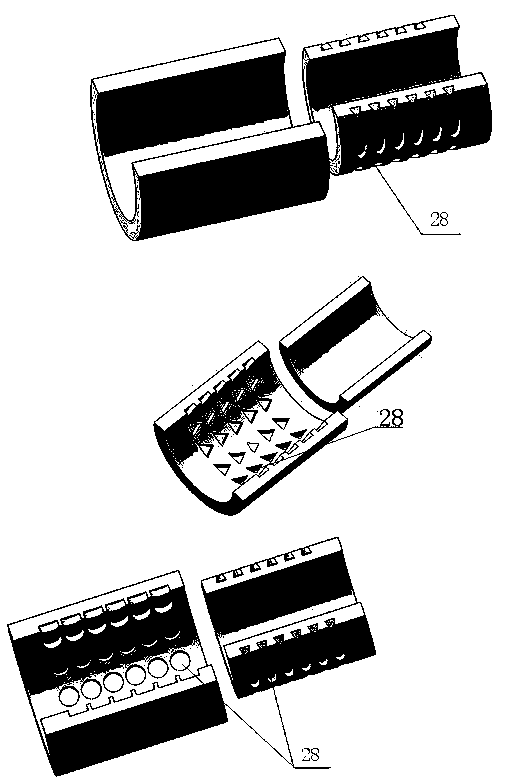

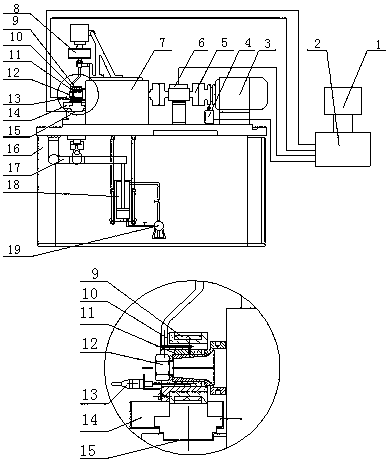

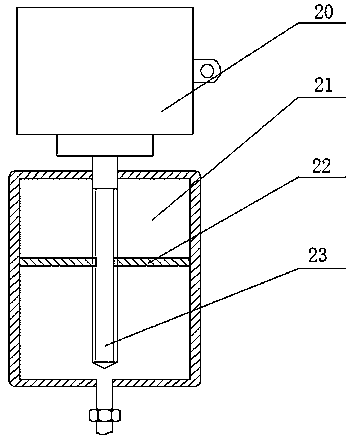

[0049] Such as Figure 1~5 As shown, a full-scale textured drill bit sliding bearing experimental device, which includes a computer 1, a data acquisition card 2, a frequency conversion motor 3, a speed sensor 4, a coupling 5, a torque sensor 6, a headstock 7, and a grease supply Device 8, heating ring 9, shaft sleeve fixture 10, sliding bearing sample 11, tightening nut 12, platinum resistance temperature sensor 13, grease collection box 14, force sensor 15, frame 16, radial loading mechanism 17, hydraulic cylinder 18. Oil pump 19. The sliding bearing sample 11 is composed of a journal 24 and a shaft sleeve 26. The rotational speed sensor 4 is an eddy current sensor fixed on the frame 16. The sliding bearing journal 11 is The hole is tapered, and the set nut 12 is used to form an interference connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com