Double-layer ITO conductive film used for touch screen and manufacturing method

A conductive film, touch screen technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of short service life, high resistivity, poor light transmittance, etc. The effect of reducing resistivity and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

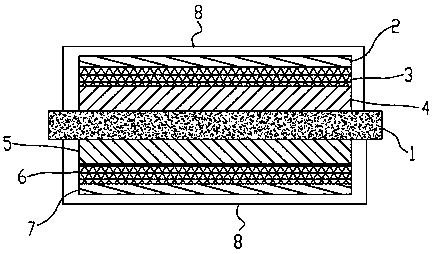

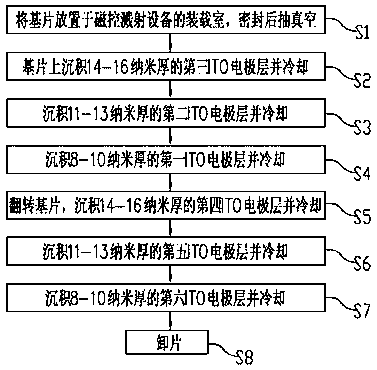

[0041] refer to figure 1 , a double-layer ITO conductive film for a touch screen, comprising a substrate 1 and an upper ITO electrode layer and a lower ITO electrode layer respectively deposited on both sides of the substrate 1; The first ITO electrode layer 2, the second ITO electrode layer 3 and the third ITO electrode layer 4, the third ITO electrode layer 4 is deposited on the substrate 1; the lower ITO electrode layer includes sequential stacking and thickness The fourth ITO electrode layer 5 , the fifth ITO electrode layer 6 and the sixth ITO electrode layer 7 are successively reduced, and the fourth ITO electrode layer 5 is deposited on the substrate 1 .

[0042] In another embodiment, the substrate 1 has a thickness of 150 microns, or 175 microns or 200 microns, and the substrate 1 is made of polyethylene terephthalate resin.

[0043] In another embodiment, an insulating electrode protection layer 8 is provided outside the first ITO electrode layer 2 and the sixth ITO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com