Efficient wheat meal screening equipment for food processing

A technology of food processing and screening equipment, which is applied in the direction of filtering, solid separation, grille, etc., which can solve the problems of poor screening effect, time-consuming and laborious, slow screening speed, etc., and achieve the effect of fast screening speed, simple operation, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

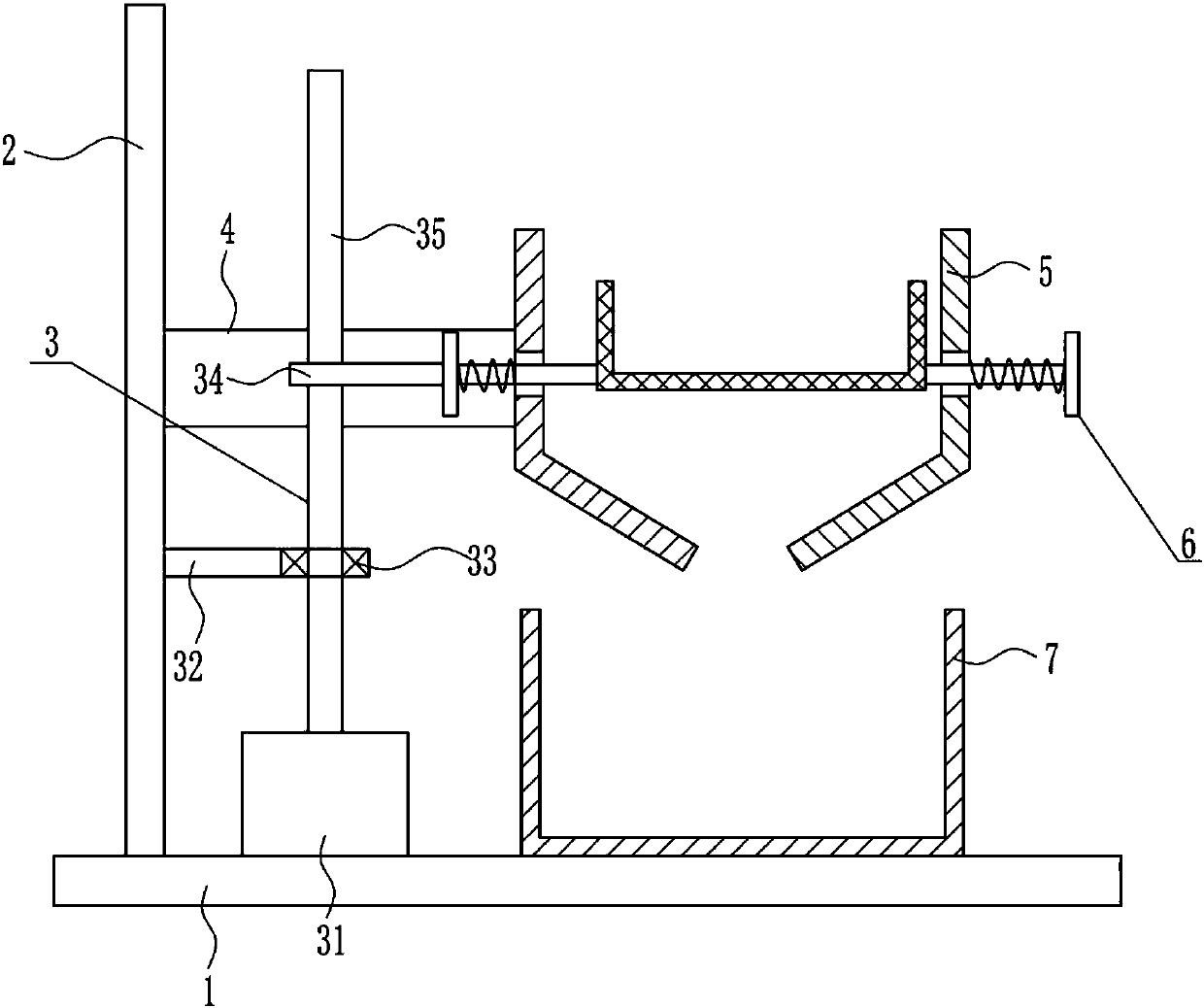

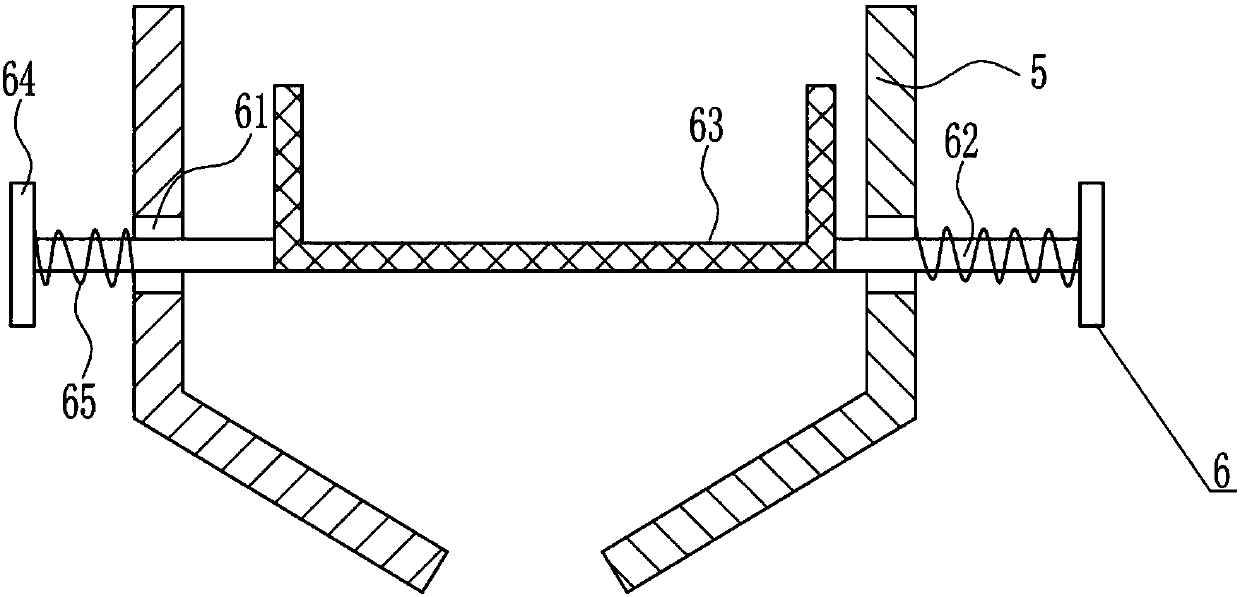

[0046] See figure 1 , An efficient screening equipment for wheat flour for food processing, including a bottom plate 1, a bracket 2, a driving device 3, a horizontal plate 4, a blocking hopper 5, a screening device 6 and a collection frame 7. The top of the bottom plate 1 is sequentially provided with brackets from left to right 2. The driving device 3 and the collecting frame 7, the middle of the right side of the bracket 2 is connected with a cross plate 4 by bolt connection, and the right side of the cross plate 4 is connected by bolts with a retaining hopper 5, and the middle of the retaining hopper 5 is provided The screening device 6, the screening component of the screening device 6 is located in the blocking material, the screening device 6 is matched with the driving device 3, and the blocking hopper 5 is located directly above the collection frame 7.

[0047] The screening device 6 cooperates with the driving device 3, and the driving device 3 can drive the screening com...

Embodiment 2

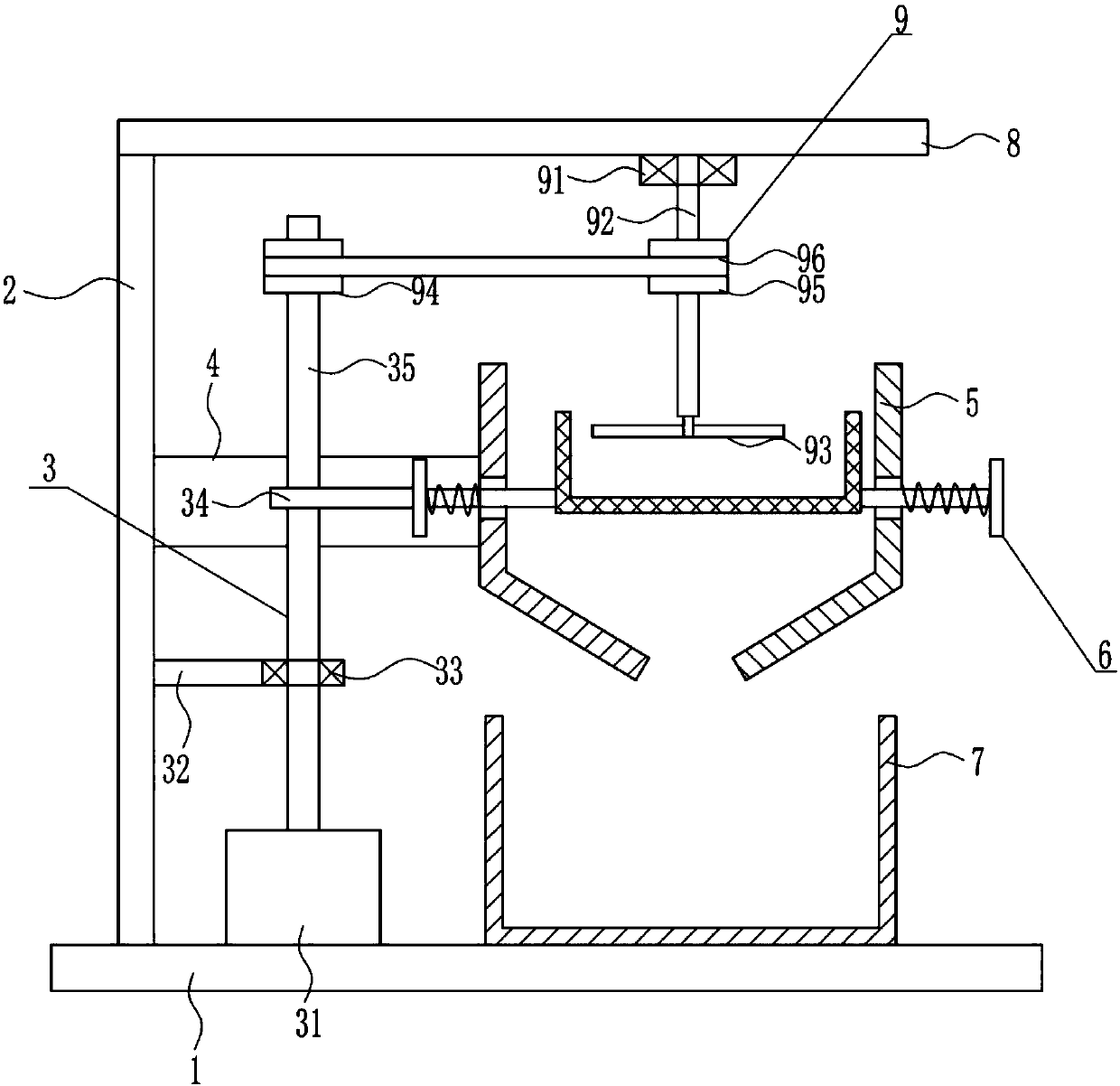

[0051] See image 3 , Different from Embodiment 1, it also includes a top plate 8 and a stirring device 9. The stirring device 9 includes a second bearing seat 91, a second rotating shaft 92, a blade 93, a first pulley 94, a second pulley 95 and a flat belt 96 , The top of the bracket 2 is horizontally connected with the top plate 8 by bolt connection, the bottom right side of the top plate 8 is connected with the second bearing seat 91 by bolt connection, and the bearing in the second bearing seat 91 is connected with the second bearing seat by interference fit. Rotating shaft 92, a blade 93 is installed at the bottom end of the second rotating shaft 92, the blade 93 is located in the screening frame 63, the upper part of the second rotating shaft 92 is connected with a second pulley 95 by a key connection, and the first rotating shaft 35 is connected by a key connection There is a first pulley 94, the first pulley 94 is located above the first cam 34, and a flat belt 96 is con...

Embodiment 3

[0053] See Figure 4 with Figure 5 The difference from Embodiment 2 is that it also includes a vibration device 10, which includes a guide plate 101, a guide rod 103, a guide ball 104, a connecting plate 105, a second spring 106 and a second cam 107, and a first motor The top of the bottom plate 1 between 31 and the collection frame 7 is vertically connected with a guide plate 101 by means of bolt connection. The upper part of the guide plate 101 is provided with a guide hole 102. The guide hole 102 is horizontally provided with a guide rod 103, and the right end of the guide rod 103 is connected There is a guide ball 104. The left end of the guide rod 103 is connected with a connecting plate 105 by bolt connection. A second spring 106 is connected between the right side of the connecting plate 105 and the left side of the guide plate 101. The second spring 106 is wound around the guide rod. 103, a second cam 107 is connected to the first rotating shaft 35 by a key connection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com