A kind of synthetic method of polybranch metal nanocrystal

A technology of metal nanocrystals and synthesis methods, applied in the field of nanomaterials, to achieve the effects of controlling shape and size, good product dispersion, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

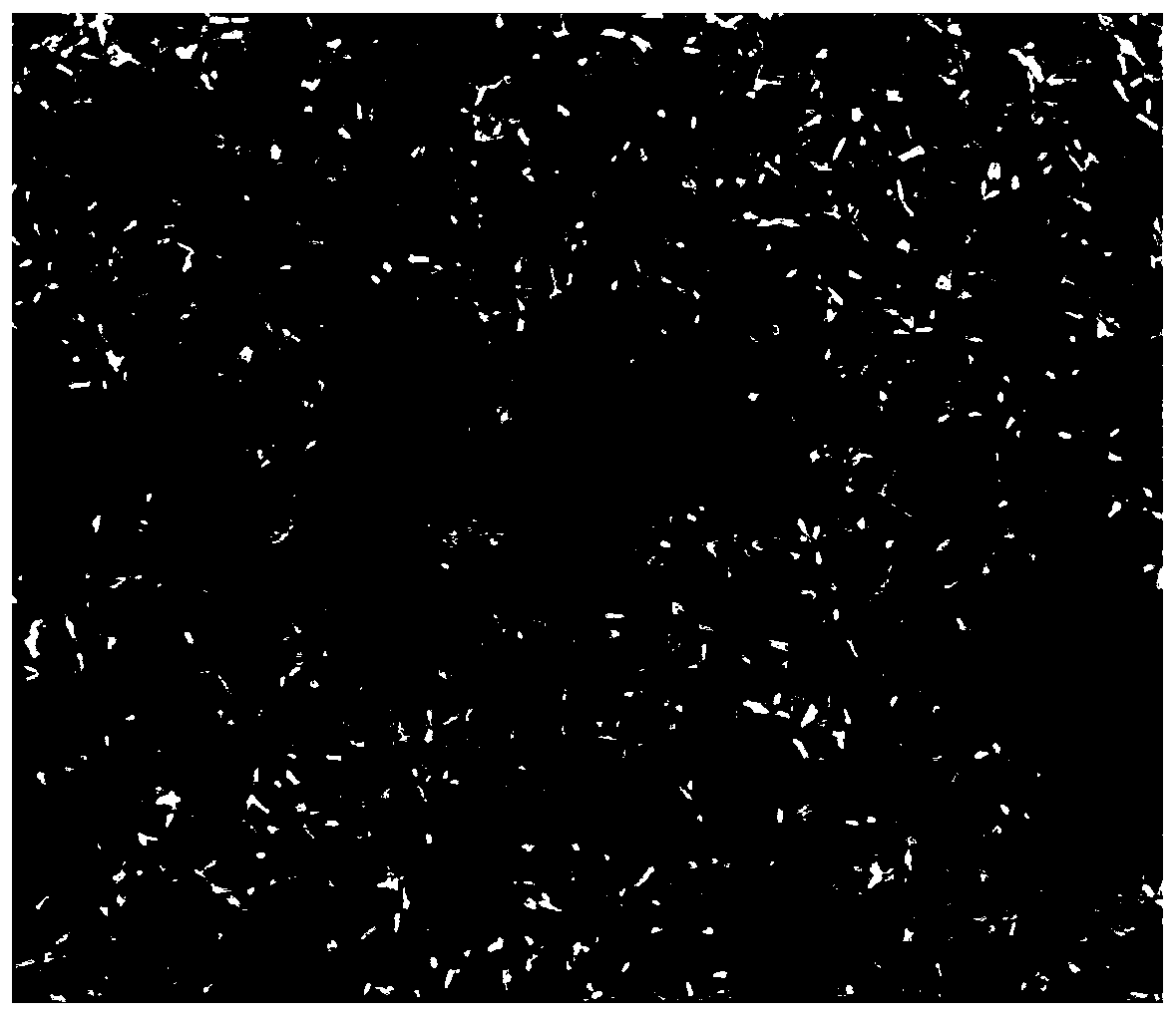

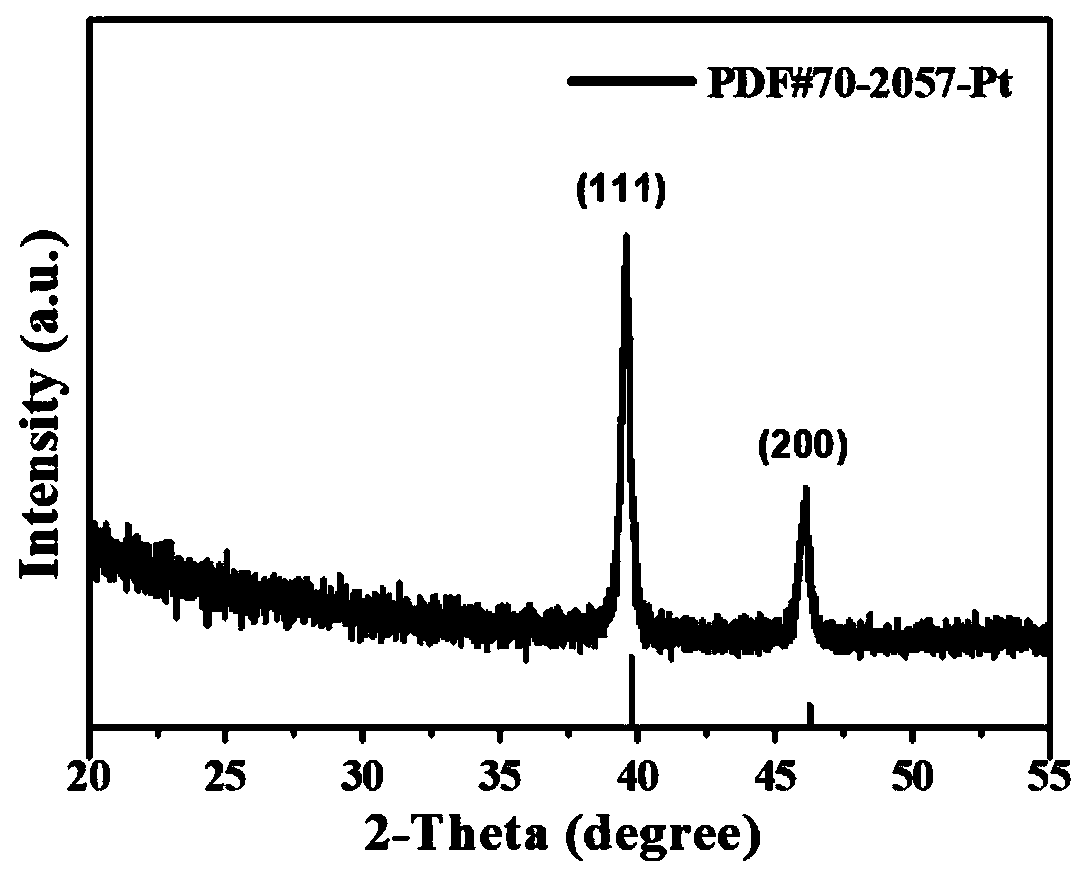

[0023] In a 25mL flask, weigh 10mg of platinum acetylacetonate, 36.5mg of cetyltrimethylammonium bromide, and 20mg of n-hexadecylformamide, add 5mL of oleylamine, and sonicate for 1 hour to make the mixture in the bottle uniform. Dispersed in solvent. The flask needs to be sealed with Teflon tape. Then put the flask in an oil bath, raise the temperature of the reaction system with the oil, and raise the temperature of the reaction system to 190° C. within 30 minutes, and keep the reaction system at 190° C. for 8 hours.

[0024] After the reaction was completed, the reaction system was naturally cooled to room temperature. Then, a mixture of 8 mL of ethanol and 1 mL of cyclohexane was added to the colloidal product, and centrifuged at a speed of 3000 r / min for 2 min. Then the supernatant was discarded, and the powder of the lower layer was retained, washed three times with 8 mL of ethanol and 1 mL of cyclohexane, and centrifuged at 3000 r / min for 2 min. The finally obtained ...

Embodiment 2

[0027] In a 25mL flask, weigh 10mg of platinum acetylacetonate, 90mg of methyltrioctylammonium bromide, and 20mg of n-hexadecylformamide, add 5mL of oleylamine, and ultrasonicate for 5 minutes to fully dissolve the mixture in the bottle into the solvent. . The flask needs to be sealed with Teflon tape. Then put the flask in an oil bath, raise the temperature of the reaction system with the oil, and raise the temperature of the reaction system to 190° C. within 30 minutes, and keep the reaction system at 190° C. for 10 hours.

[0028] After the reaction was completed, the reaction system was naturally cooled to room temperature. Then, a mixture of 8 mL of ethanol and 1 mL of cyclohexane was added to the colloidal product, and centrifuged at a speed of 3000 r / min for 2 min. Then the supernatant was discarded, and the powder of the lower layer was retained, washed three times with 8 mL of ethanol and 1 mL of cyclohexane, and centrifuged at 3000 r / min for 2 min. The final resul...

Embodiment 3

[0030] A method for synthesizing multi-branched Pt metal nanocrystals, using platinum acetylacetonate as a metal precursor, n-hexadecyl formamide as a reducing agent, methyl trioctylammonium bromide as a surfactant and a structure-directing agent , using oleylamine as a solvent to obtain multi-branched Pt metal nanocrystals by a "one-pot method".

[0031] Pt(acac) 2 , n-hexadecyl formamide, and methyl trioctyl ammonium bromide were poured into the flask, and then oleylamine was added to dissolve the mixture in oleylamine, ultrasonicated for 50 minutes to fully dissolve and disperse, and then the flask was placed in In an oil bath, heat up and raise the reaction temperature from room temperature to 210°C within 30 minutes, and then maintain this temperature for 11 hours. After the reaction, cool naturally to room temperature, and add 8 mL of The mixed solution of ethanol and 1mL cyclohexane was ultrasonically mixed, and centrifuged. The obtained solid was washed 5 times with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com