Film spraying head sealing device for film spraying machine and die lip closing method applying film spraying head sealing device

A technology of sealing device and laminating machine, applied in coating and other directions, can solve the problems of on-site maintenance personnel working troubles, time-consuming and laborious operation, affecting maintenance efficiency and production process, etc., to reduce the pre-start process, avoid coke, production The effect of benefit guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

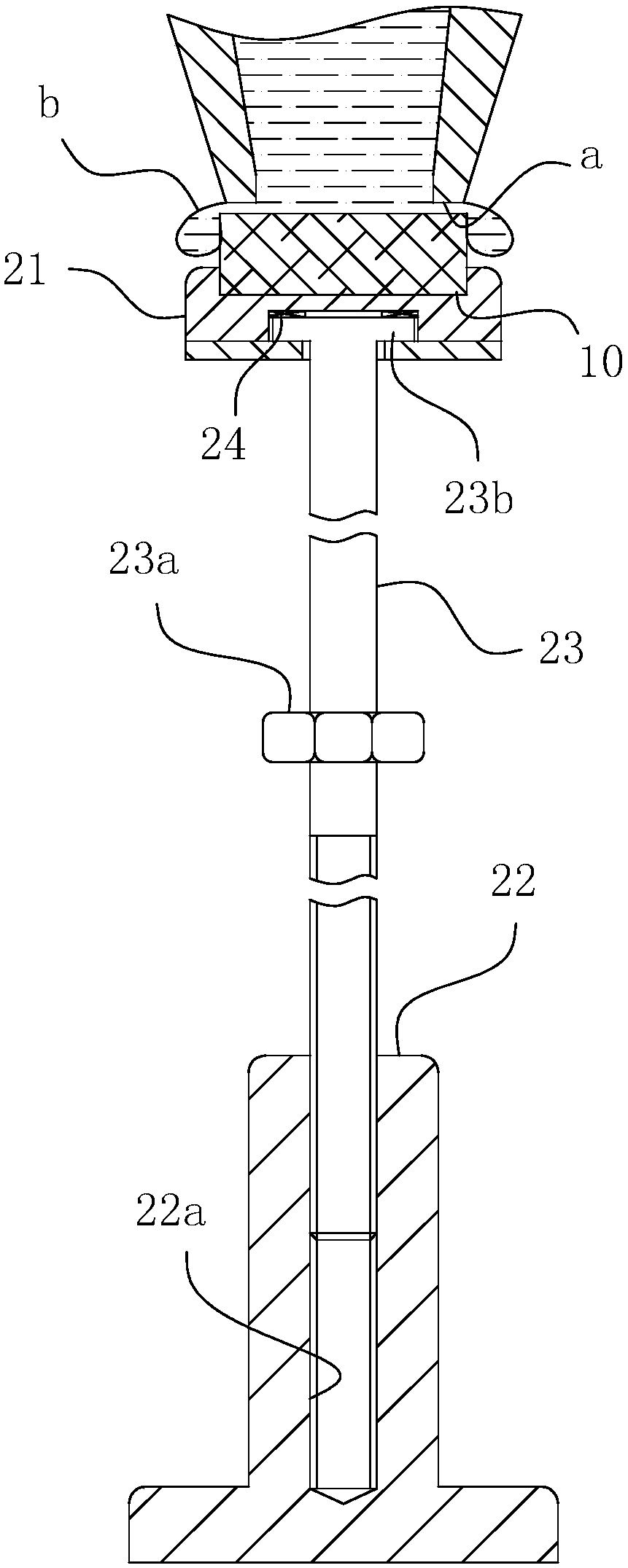

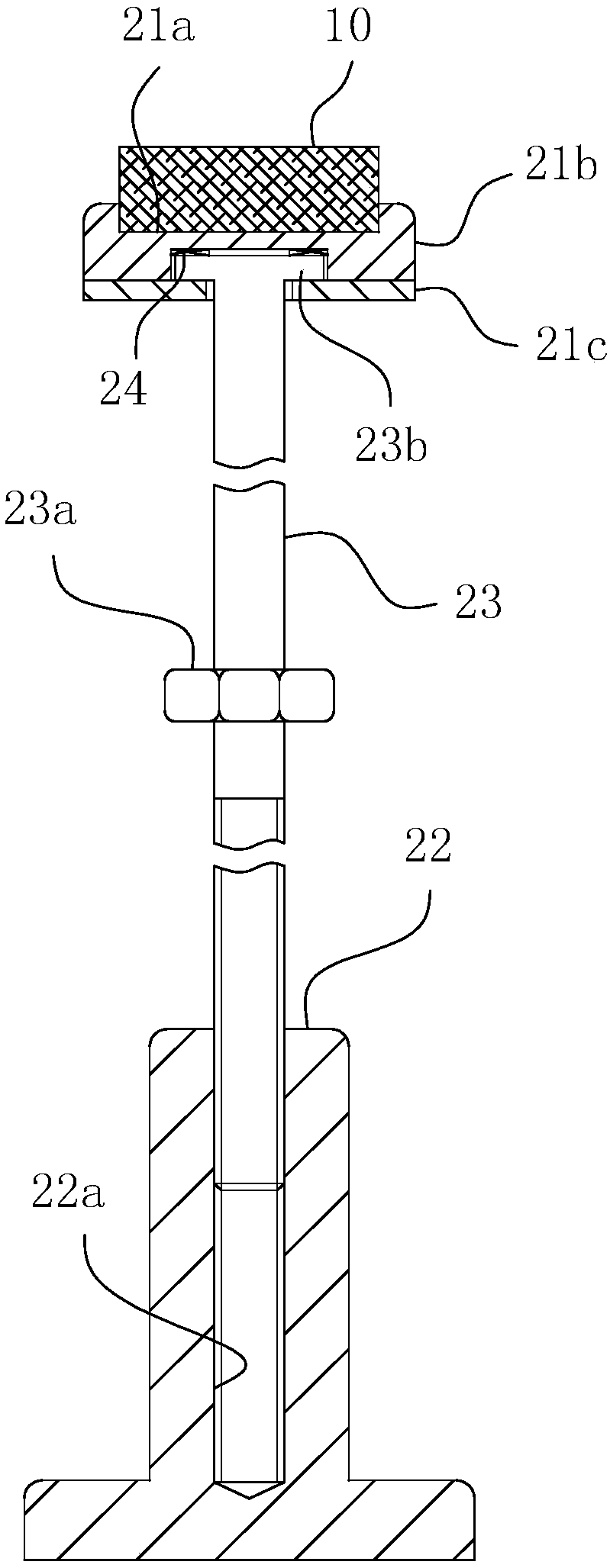

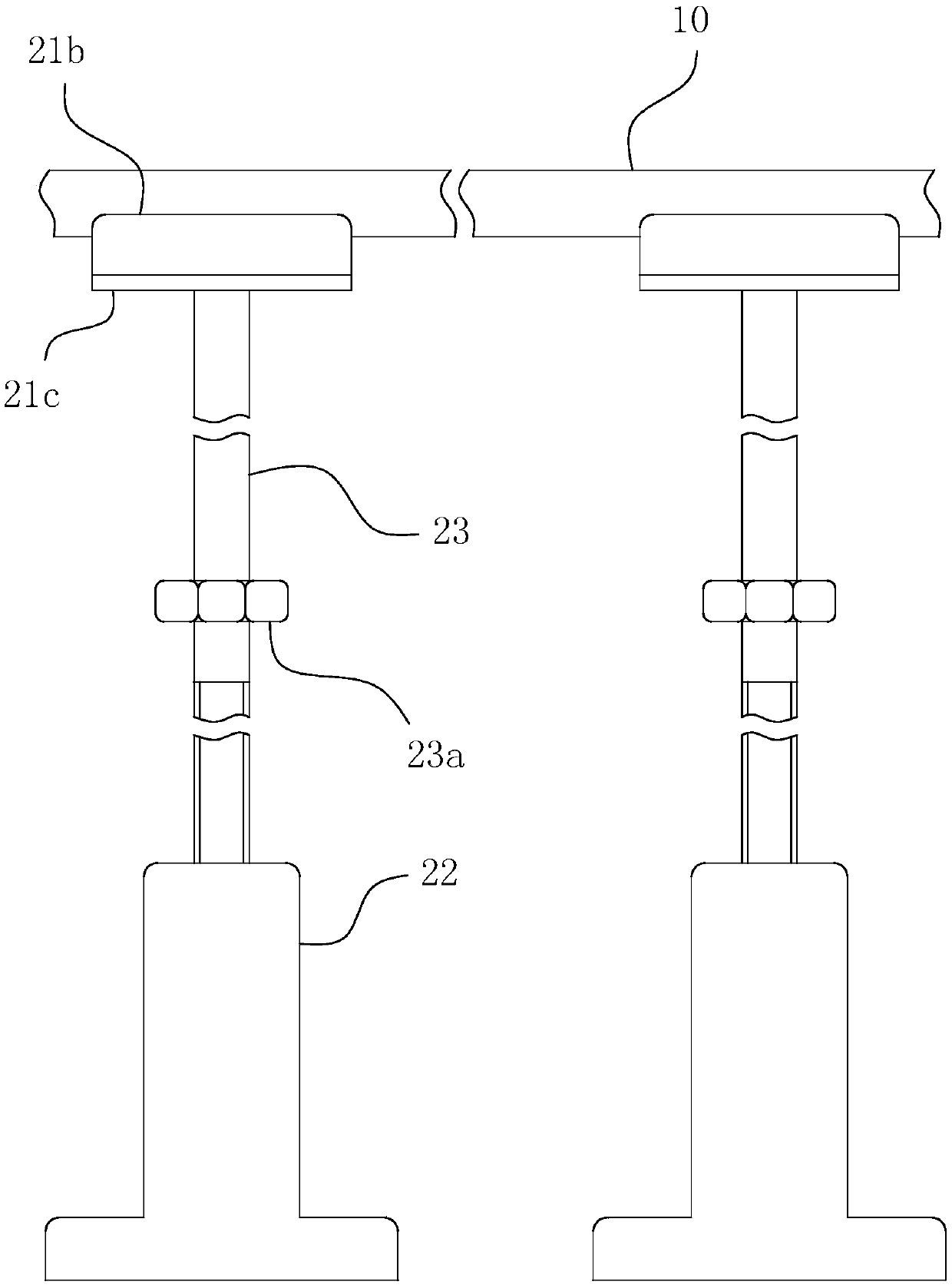

[0032] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the accompanying drawings:

[0033] Concrete structure of the present invention refers to Figure 1-3 As shown, its main structure includes a copper rectangular plate-shaped sealing plate 10 and a bracket for supporting the sealing plate 10 from bottom to top. when used as image 3 In the embodiment shown, two sets of brackets are preferred, and they can be placed at both ends of the lip a of the coating head in the length direction during use.

[0034] The shape reference of the bracket Figure 1-2 As shown, it includes a base 22 , a support rod 23 and a support platform 21 sequentially from bottom to top. The shape of the base 22 is a two-stage stepped shaft shape with a thick bottom and a thin top, and a threaded hole 22a is recessed on the top surface of the base 22 . The lower shaft of the support rod 23 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com