Nickel-hydrogen battery used in extremely cold environment and preparation method of nickel-hydrogen battery

A technology for nickel-metal hydride batteries and extremely cold environments, which is applied in the manufacture of nickel batteries, alkaline batteries, and battery electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

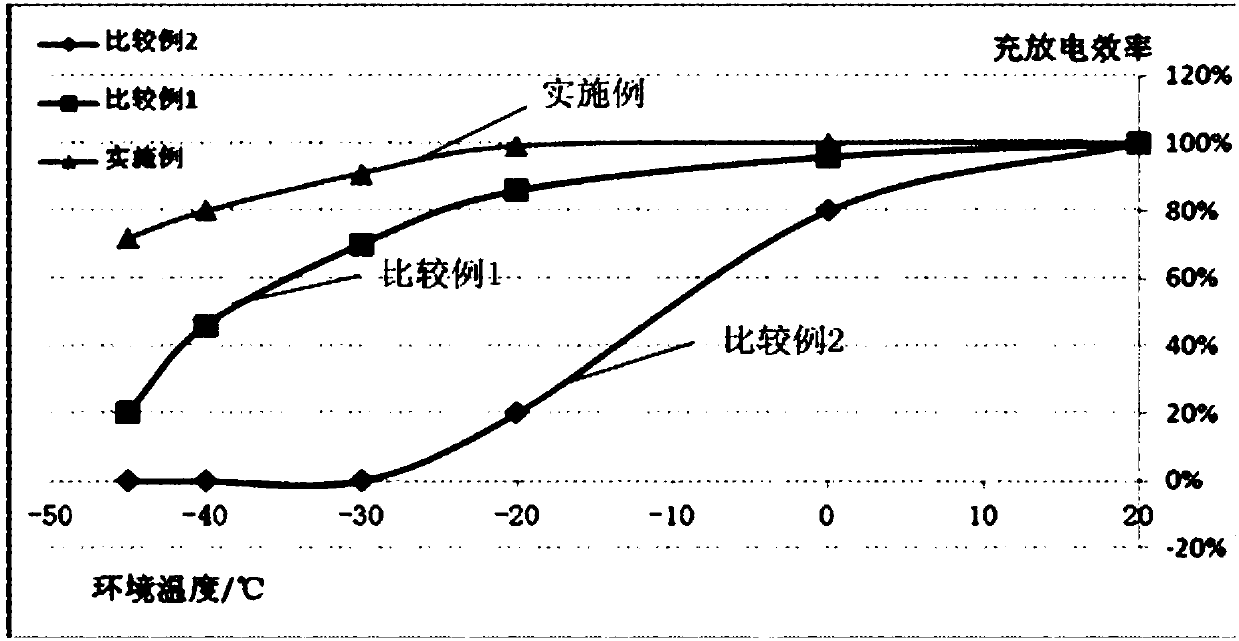

Examples

Embodiment 1

[0040] S1. Take foamed nickel metal as the positive electrode substrate, and compact the edge area of the positive electrode substrate to form a white edge with a width of 2 mm;

[0041] S2. After mixing the positive electrode active material evenly, fill it on the positive electrode substrate obtained in step S1, roll and cut it, and make the positive electrode sheet of the nickel-metal hydride battery;

[0042] S3. Take foamed metal copper as the negative electrode substrate, with 40% A2B7 hydrogen storage alloy powder, 56.2% AB5 hydrogen storage alloy powder, 3% T255 ultrafine metal nickel powder, 0.3% carbon nanotubes, 0.5% Yb2O3 forms an additive combination, and then fills the additive combination on the negative electrode substrate, and obtains the negative electrode sheet through drying and rolling.

[0043] S4. Prepare electrolyte and separator, the weight ratio of electrolyte is: KOH: LiOH: CsOH: glycerol: H2O=50:2:4:0.5:100;

[0044] S5. Assemble the positive pol...

Embodiment 2

[0046] S1. Take foamed nickel metal as the positive electrode substrate, and compact the edge area of the positive electrode substrate to form a 2.2mm wide white edge;

[0047] S2. After mixing the positive electrode active material evenly, fill it on the positive electrode substrate obtained in step S1, roll and cut it, and make the positive electrode sheet of the nickel-metal hydride battery;

[0048] S3. Take the foamed metal copper as the negative electrode substrate, with 28% A2B7 hydrogen storage alloy powder, 50% AB5 hydrogen storage alloy powder, 1% T255 ultrafine metal nickel powder, 0.1% carbon nanotube, 0.3% Y2O3 forms an additive combination, and then fills the additive combination on the negative electrode substrate, and obtains the negative electrode sheet through drying and rolling.

[0049] S4. Prepare electrolyte and separator, the weight ratio of electrolyte is: KOH: LiOH: CsOH: glycerol: H2O=50:1:2:0.3:100;

[0050] S5. Assemble the positive pole piece, t...

Embodiment 3

[0052] S1. Take foamed nickel metal as the positive electrode substrate, and compact the edge area of the positive electrode substrate to form a 2.5mm wide white edge;

[0053] S2. After mixing the positive electrode active material evenly, fill it on the positive electrode substrate obtained in step S1, roll and cut it, and make the positive electrode sheet of the nickel-metal hydride battery;

[0054]S3. Take the foamed metal copper as the negative electrode substrate, with 30% A2B7 hydrogen storage alloy powder, 51% AB5 hydrogen storage alloy powder, 1.2% T255 ultrafine metal nickel powder, 0.15% carbon nanotube, 0.35% Er2O3 forms an additive combination, and then fills the additive combination on the negative electrode substrate, and then obtains the negative electrode sheet through drying and rolling.

[0055] S4. Prepare electrolyte and separator, the weight ratio of electrolyte is: KOH: LiOH: CsOH: glycerol: H2O=50:1.2:2.5:0.4:100;

[0056] S5. Assemble the positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com