Peanut Sheller

A technology of peeling machine and peanuts, which is applied in the field of agricultural machinery, can solve the problems of broken peanuts and other problems, and achieve the effect of complete peanuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

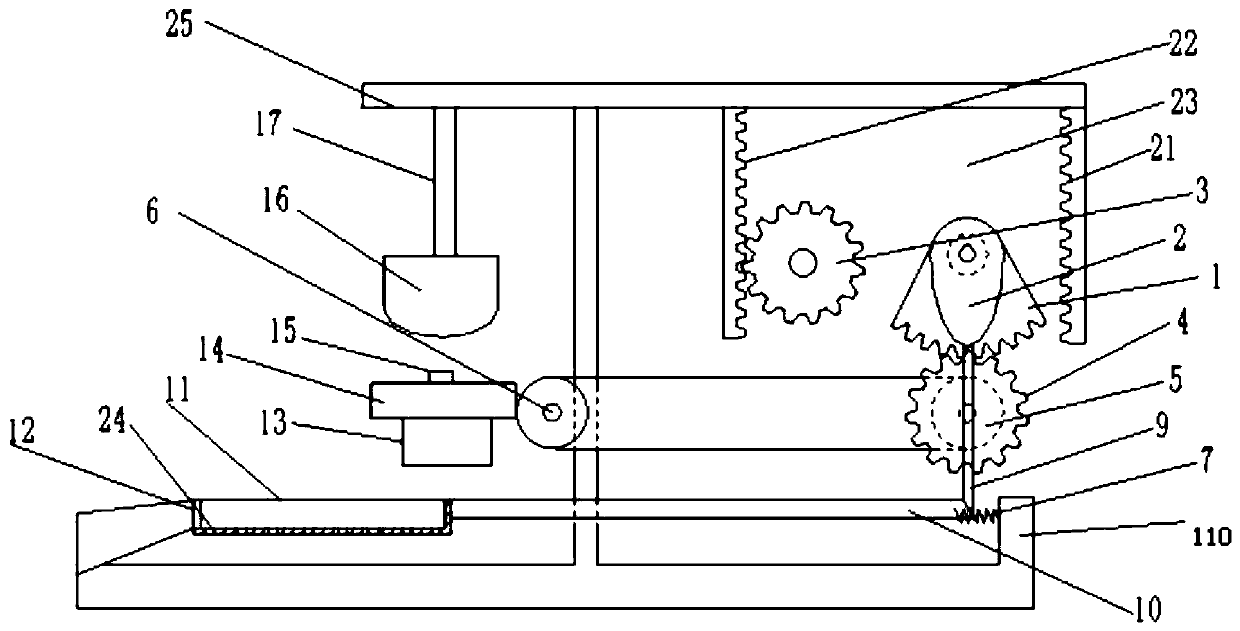

[0022] Embodiment one is basically as attached figure 1 , 3 , as shown in 4:

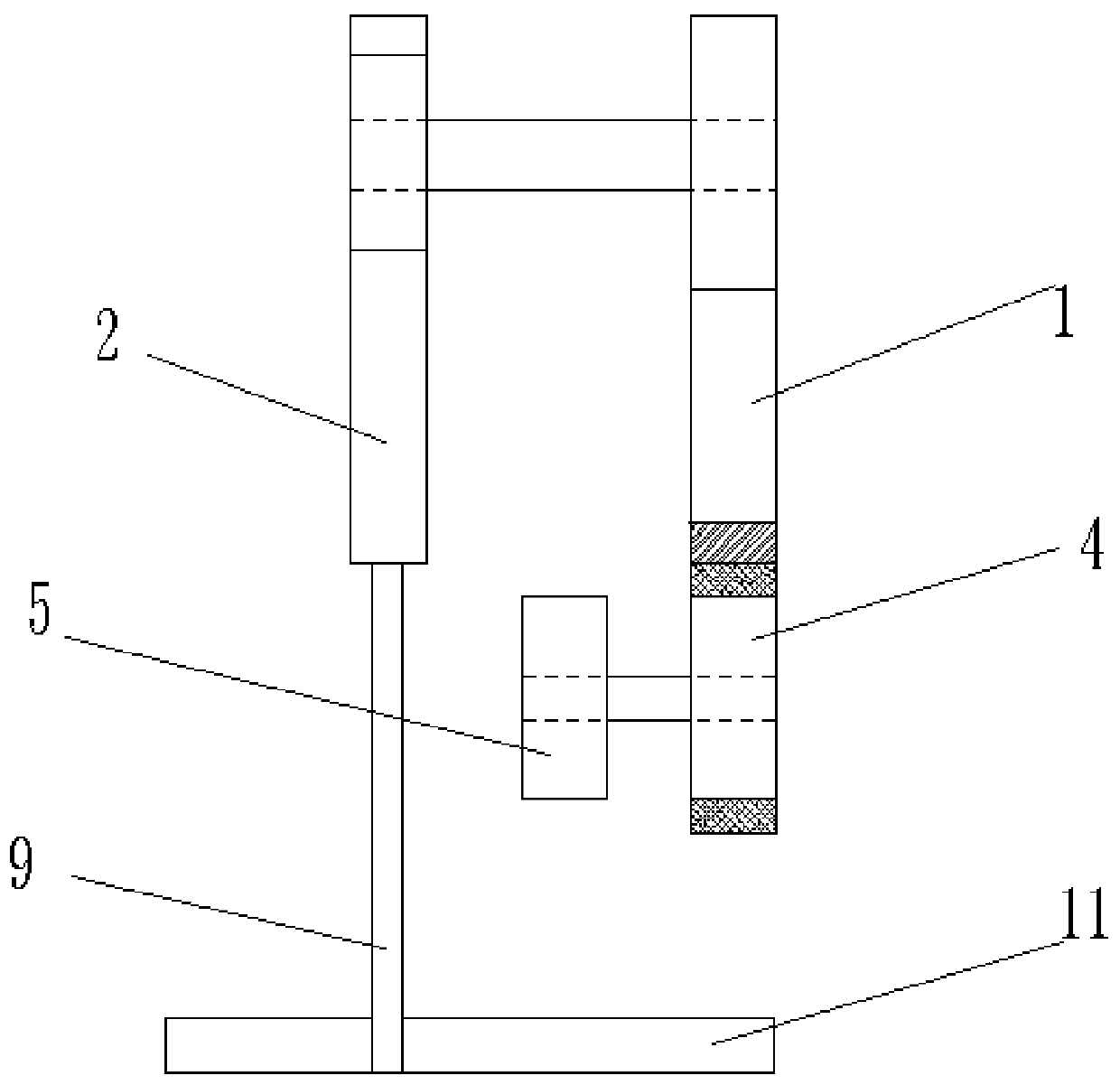

[0023] The peanut sheller includes a frame 110, on which a fan gear 1, a first gear 3, a second gear 4, a cross bar 25 and a material receiving platform 14 are installed, the first gear 3 is on the left side of the fan gear 1, and the second gear is on the left side of the fan gear 1. The second gear 4 is on the lower side of the sector gear 1, and the cross bar 25 is fixedly connected with the first rack 21 and the second rack 22; the first gear 3, the second gear 4 and the first rack 21 are engaged with the sector gear 1 for transmission , the second rack 22 meshes with the left side of the first gear 3, the second rack 2 meshes with the right side of the sector gear 1, the leftmost end of the cross bar 25 is welded with a ram 17, and the lower part of the ram 17 is also welded with a ram 16, The cross bar 25 is slidably installed on the frame 110, so that the cross bar 25 can only move up and d...

Embodiment 2

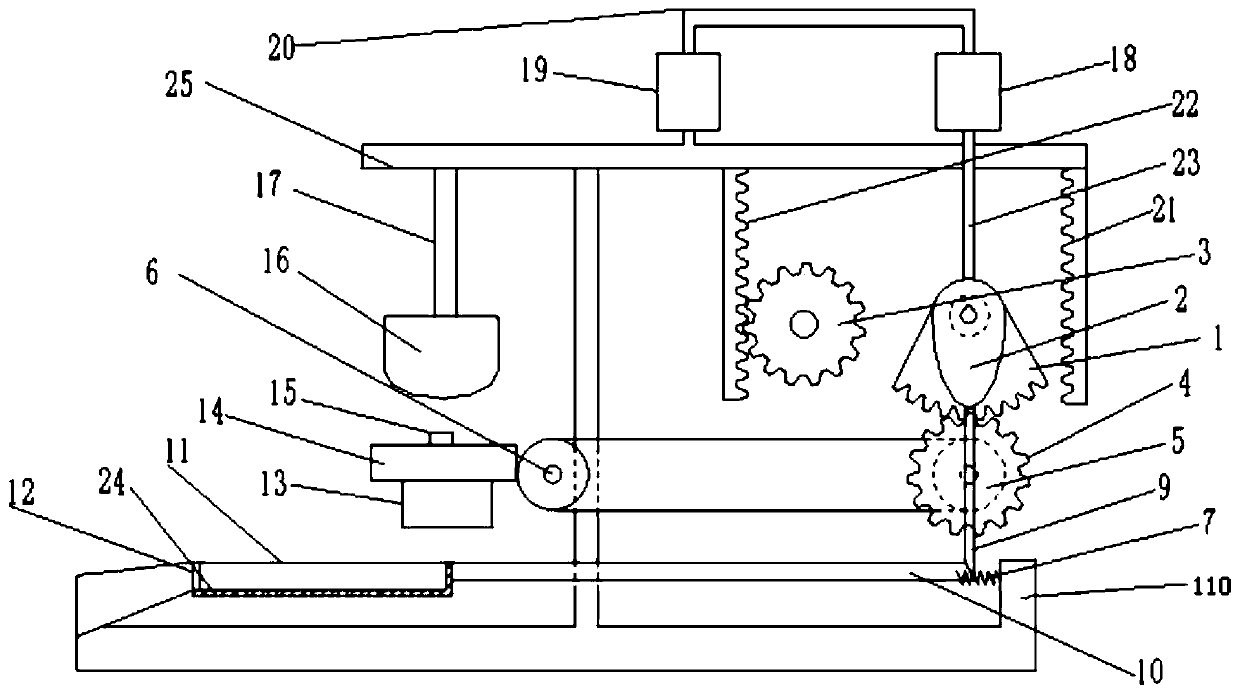

[0025] Embodiment two is basically as attached figure 2 , 3 , as shown in 4:

[0026]The difference from Embodiment 1 is only that a piston rod 23 is connected above the cam 2, a first piston cylinder 18 is provided on the piston rod 23, a second piston cylinder 19 is provided on the cross bar 25, and a U-shaped piston is passed between the two cylinders. Rod 20 is connected. When the sector gear 1 rotates to the lowest position, the cam 2 also rotates to the lowest position, at this time the piston rod 23 also moves to the lowest position, the air pressure in the first piston cylinder 18 decreases, and the U-shaped piston rod 20 moves down accordingly , acting on the second piston barrel 19, the air pressure in the second piston barrel 19 increases, causing the cross bar 25 to move down, and then drives the bumper 16 to hit the material receiving platform 14; when the uppermost end of the sector gear 1 rotates, the cam 2 also Rotate to the highest point, and now the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com