Metal filter bag capable of being conveniently spliced and mounted

A technology of metal filter bags and connectors, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as insufficient pre-tightening force, inconvenient installation and operation, and long operating hours to reduce extrusion. Compression deformation, protection of product performance, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

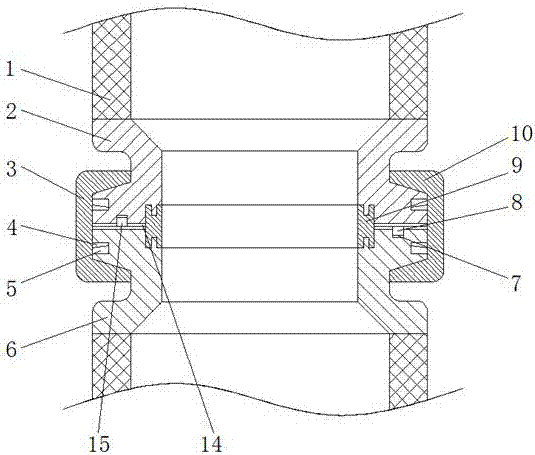

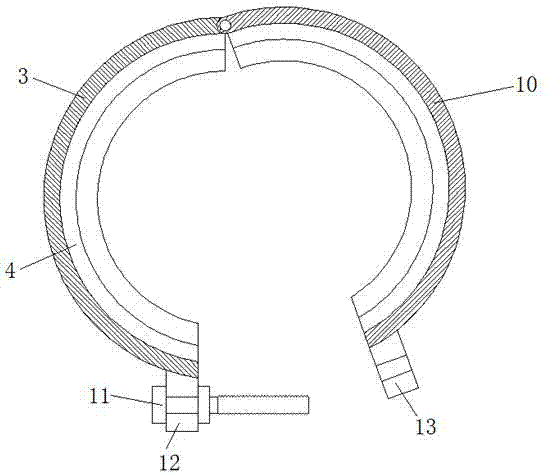

[0019] refer to Figure 1-2 , a metal filter bag that is convenient for splicing and installation, including an upper connector 2 and a lower connector 6, the bottom of one side of the inner wall of the upper connector 2 and the top of one side of the inner wall of the lower connector 6 are provided with I-shaped connecting grooves, and The inner walls of the two I-shaped connecting grooves are sleeved with the same sealing ring 9, the bottom outer wall of the upper connector 2 and the top outer wall of the lower connector 6 are fixed with elastic pads 14 by screws, and the bottom outer wall of the upper connector 2 There is a connecting groove 15 on one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com