Mechanical pipeline cleaning brush

A pipeline cleaning and mechanical technology, applied in the field of mechanical tools, can solve the problem of general cleaning effect of stubborn oil pollution, and achieve the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

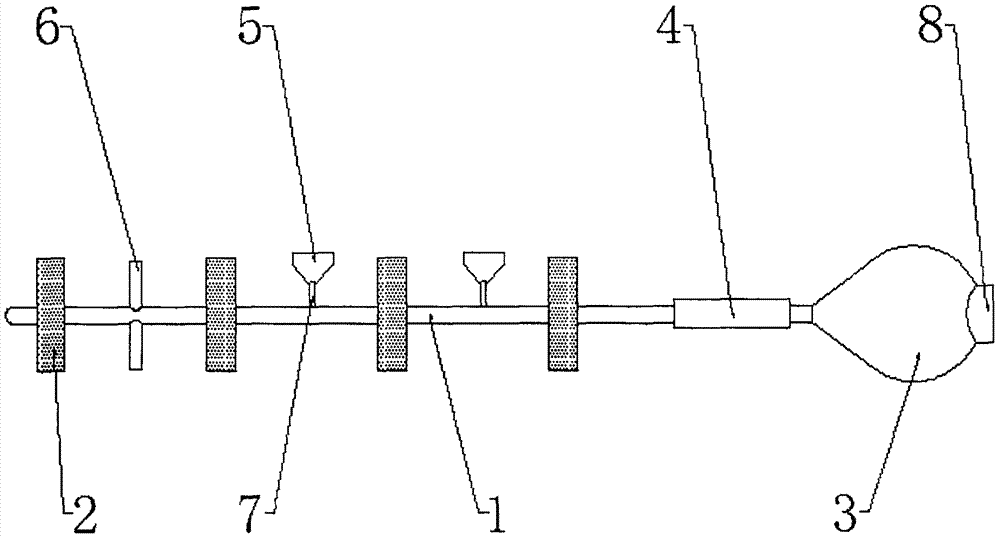

[0016] Such as figure 1 As shown, the mechanical pipeline cleaning brush includes a circular tube-shaped support tube 1 with an open end. The open end of the support tube 1 is connected with a liquid storage bottle 3. The opening of the liquid storage bottle 3 is provided with a bottle cap 8. There are several brush discs 2 in the shape of disc-shaped brushes. The diameters of the brush discs 2 are all equal, and the diameter of the brush discs 2 is designed to be equal to the inner diameter of the tubular parts to be cleaned, so that the brush discs 2 can be fully inserted Brush the inner wall of the steel pipe.

[0017] The side of the support tube 1 is vertically provided with two circular tube-shaped liquid injection pipes 6, which are directly connected to the inner cavity of the support pipe 1. The liquid pipe 6 can be plugged into the steel pipe inside. Support pipe 1 side is vertically provided with two elastic rods 7, and the end of two elastic rods 7 is all equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com