Variable-rigidity part suction device and plate suction bending method

A technology of suction device and variable stiffness, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of slow speed, large volume, and inability to arrange suction cups when picking up and releasing parts, so as to achieve automation efficiency. High, small size, fast absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

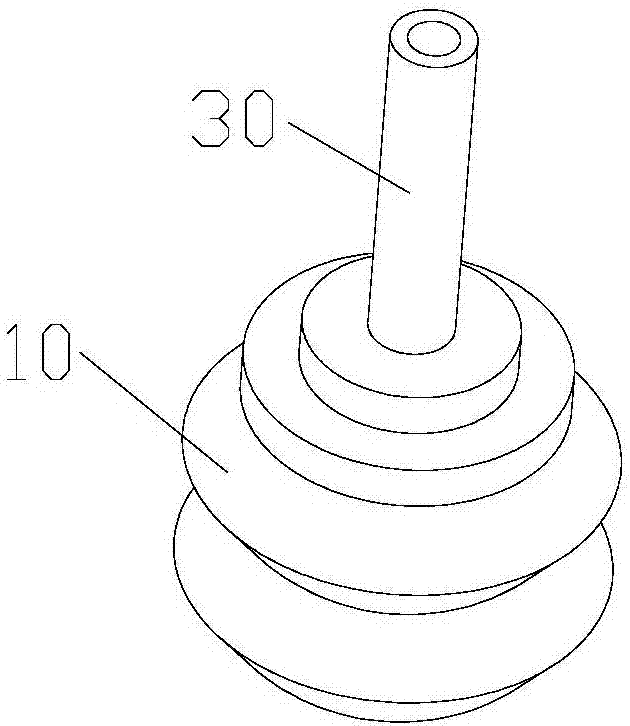

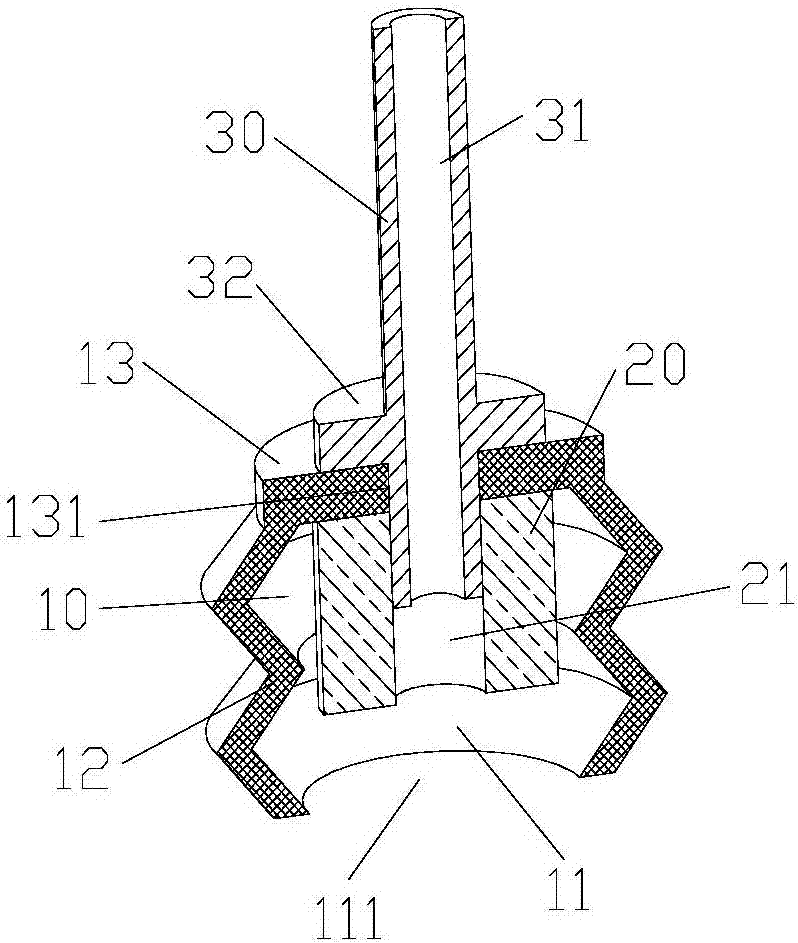

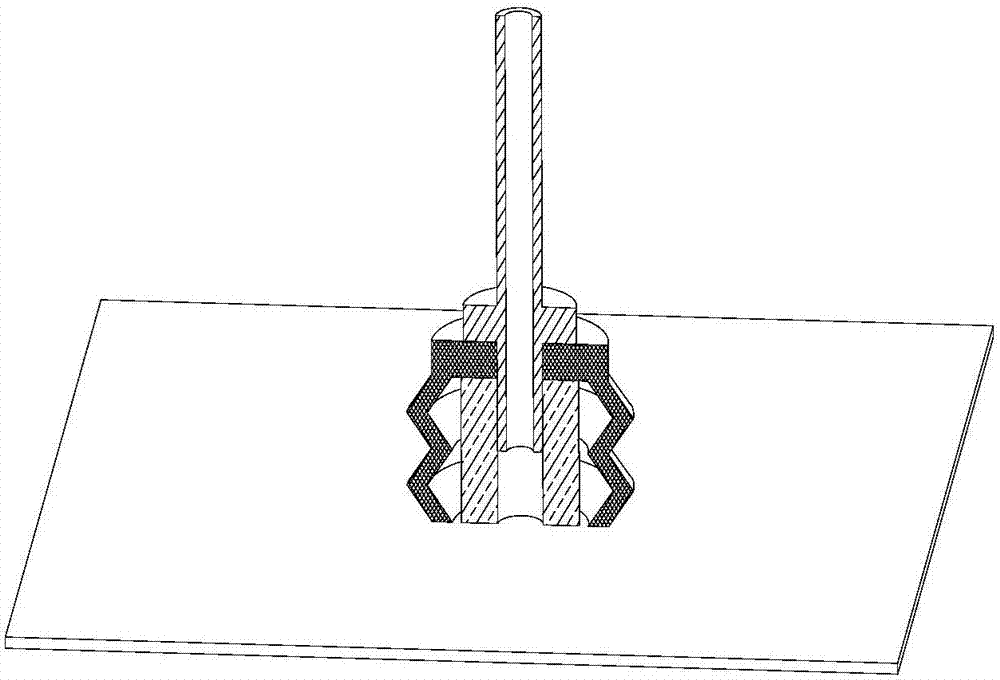

[0046] Such as figure 1 with figure 2 As shown, a variable stiffness part suction device includes a flexible organ cavity 10, an electromagnet 20, a connecting rod 30 and a vacuum pump.

[0047] The flexible organ cavity is mainly formed by the ring-shaped suction cup 11, the flexible telescopic side wall 12 and the top surface 13. Furthermore, the ring-shaped suction cup, the flexible telescopic side wall and the top surface are preferably integrated.

[0048] The annular suction cup is arranged at the bottom of the flexible telescopic side wall, and the center of the annular suction cup is provided with a suction cup central hole 111 .

[0049] The top surface is arranged on the top of the flexible telescopic side wall, and the center of the top surface is provided with a top surface central hole 131 .

[0050] The ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com