Mechanical arm

A manipulator and plane technology, applied in the field of manipulators, can solve the problems of bump damage on the piston rod surface, low efficiency of small blanking, high labor cost, etc., and achieve the effect of avoiding bump damage, high labor cost and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

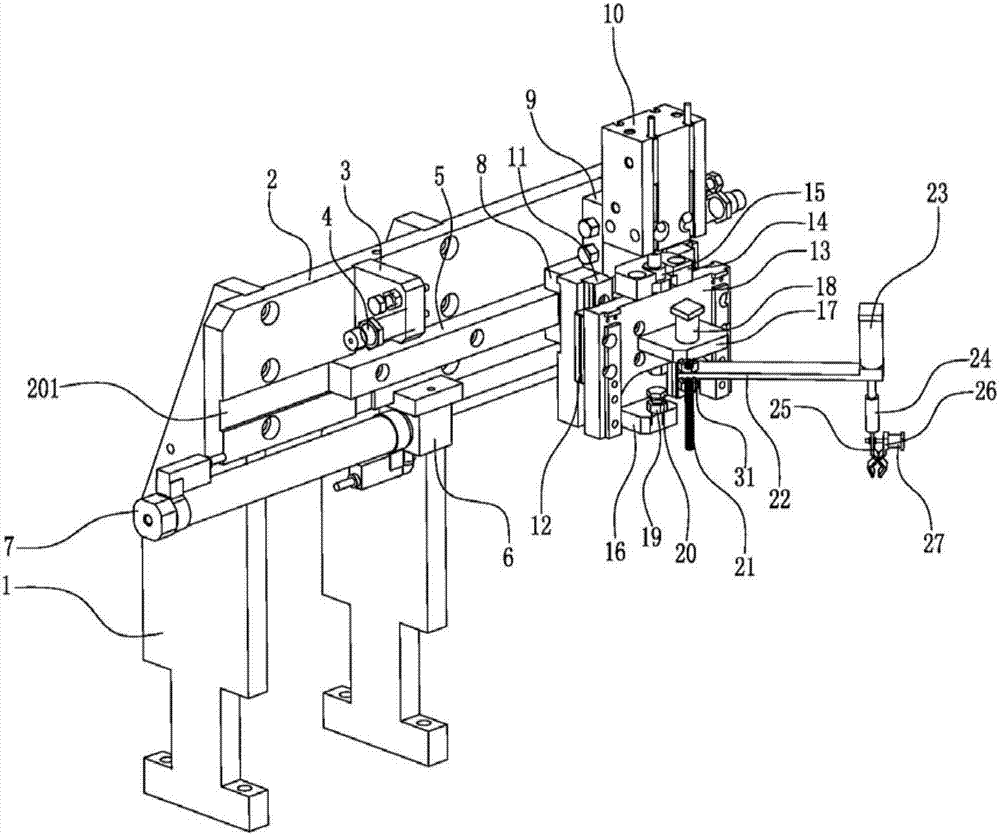

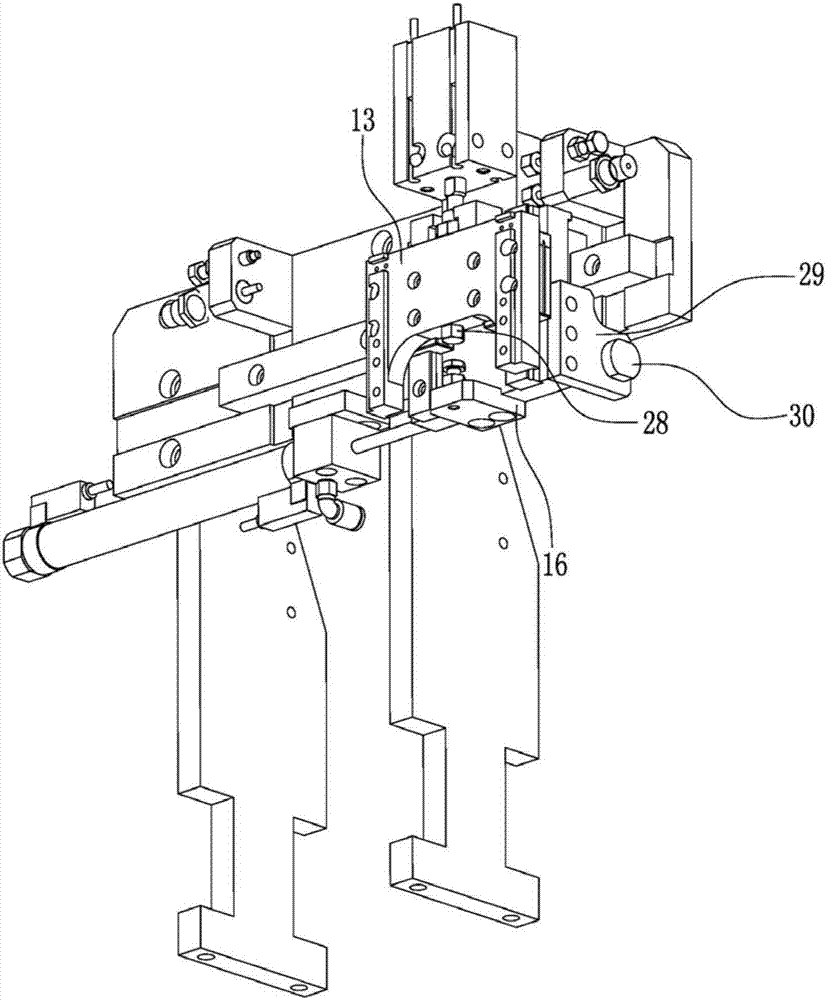

[0015] Such as Figure 1~2 As shown, a manipulator includes a support block 1, a back plate 2, an extension block 3, a buffer 4, a first guide rail 5, a positioning block 6, a first cylinder 7, a first slider 8, a side block 29, and a shaft sleeve 30. Lifting assembly and swing arm assembly; two support blocks 1 distributed parallel to each other are fixed on the back plane of the back plate 2; the lower ends of the two support blocks 1 are fixed at the designated position of the machine tool; the front side of the back plate 2 There are positioning grooves 201 distributed horizontally and horizontally on the plane, the first guide rail 5 is embedded and fixed in the positioning groove 201, and the first slider 8 is sleeved and connected to the outside of the first guide rail 5; the front side plane of the back plate 2 is fixed with The extension block 3, the extension block 3 is located above the first guide rail 5, the buffer 4 distributed horizontally and horizontally is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com