Energy-saving water supply system for office factory building of enterprise

A water supply system and energy-saving technology, applied in water supply pipeline systems, water supply devices, water supply devices, etc., can solve the problems of wasting electric energy, large water consumption, affecting production, etc., to reduce operating costs, improve utilization, and save water sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

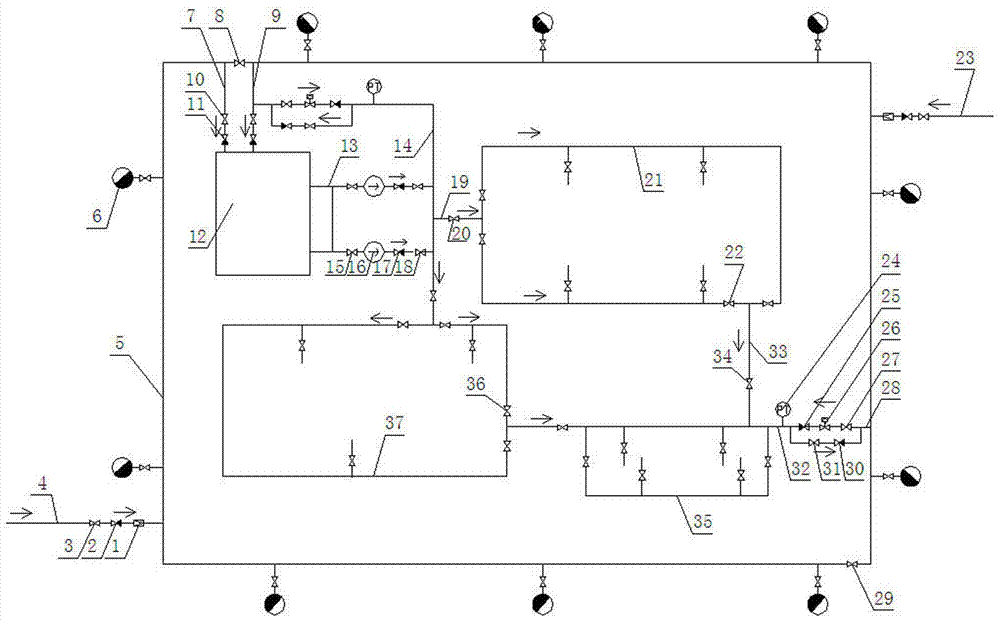

[0016] Specific implementation manner one: such as figure 1 As shown, an energy-saving water supply system for corporate office buildings includes a storage tank 12 and a main ring pipe 5 arranged along the main ring road. The main ring pipe 5 is sequentially provided with a first water inlet pipe 4 and a first valve 8. The second inlet pipe 23 and the second valve 29. The first inlet pipe 4 and the second inlet pipe 23 are both connected to the municipal water supply system. The first inlet pipe 4 and the second inlet pipe 23 are arranged diagonally, The first water inlet pipe 4 and the second water inlet pipe 23 are provided with a first valve 3, a first check valve 2 and a flow meter 1 in sequence along the water inlet direction. The main ring pipe 5 is provided with fire protection at corresponding positions. Bolt 6, a third water inlet pipe 7 and a fourth water inlet pipe 9 are provided between the reservoir 12 and the main annular pipe 5. The third water inlet pipe 7 and t...

specific Embodiment approach 2

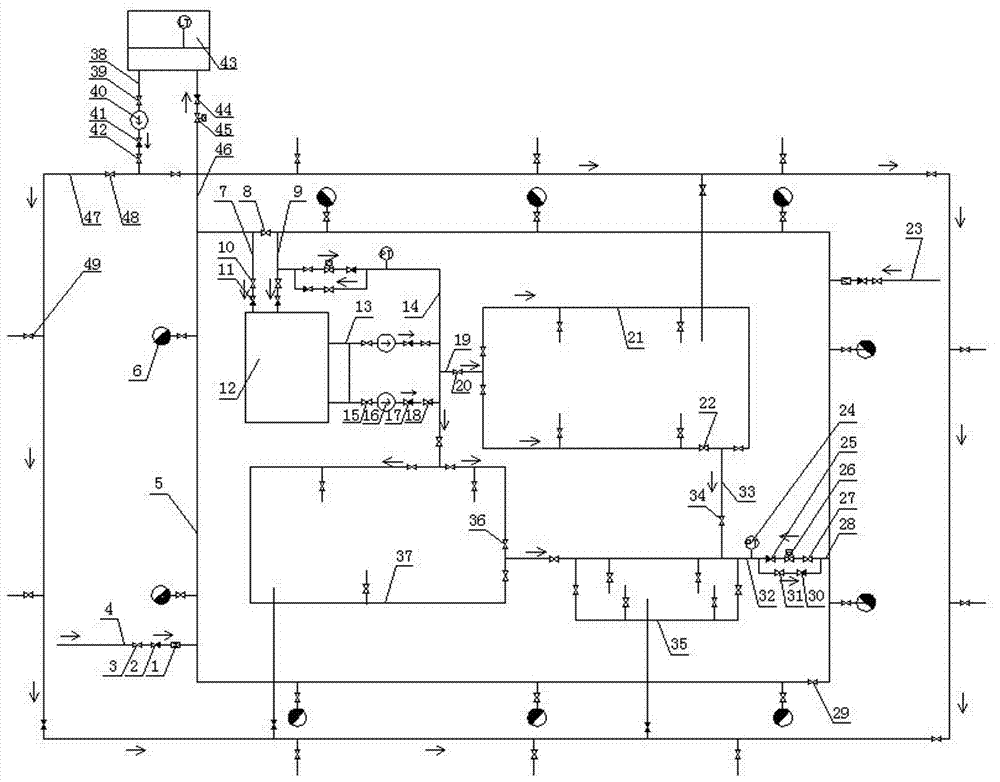

[0021] Specific implementation manner two: such as figure 2 As shown, the water supply system described in the first embodiment further includes a reclaimed water station 43. The mild sewage generated by each factory and office building flows into the reclaimed water station 43 through sewers or laying pipes (not shown in the figure). Between the reclaimed water station 43 and the main loop pipe 5, there is a clear water pipe 46 for supplying water to the reclaimed water station 43. On the clear water pipe 46, an electric valve 45 and a sixth check valve 44 are installed in sequence along the inflow direction of the clear water. A water pipe 38 is provided on the reclaimed water station 43. A ninth valve 39, a water pump 40, a seventh check valve 41, and a tenth valve 42 are installed on the water pipe 38 along the direction of water discharge. In the ring tube 47, a plurality of eleventh valves 48 are evenly installed on the auxiliary ring tube 47, and the auxiliary ring tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com