Box body of gearbox for rail transit vehicle

A technology for rail transit vehicles and gearboxes, which is applied in the field of rail vehicle transmission systems and can solve problems such as the inability of the lubrication system to meet the requirements of working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

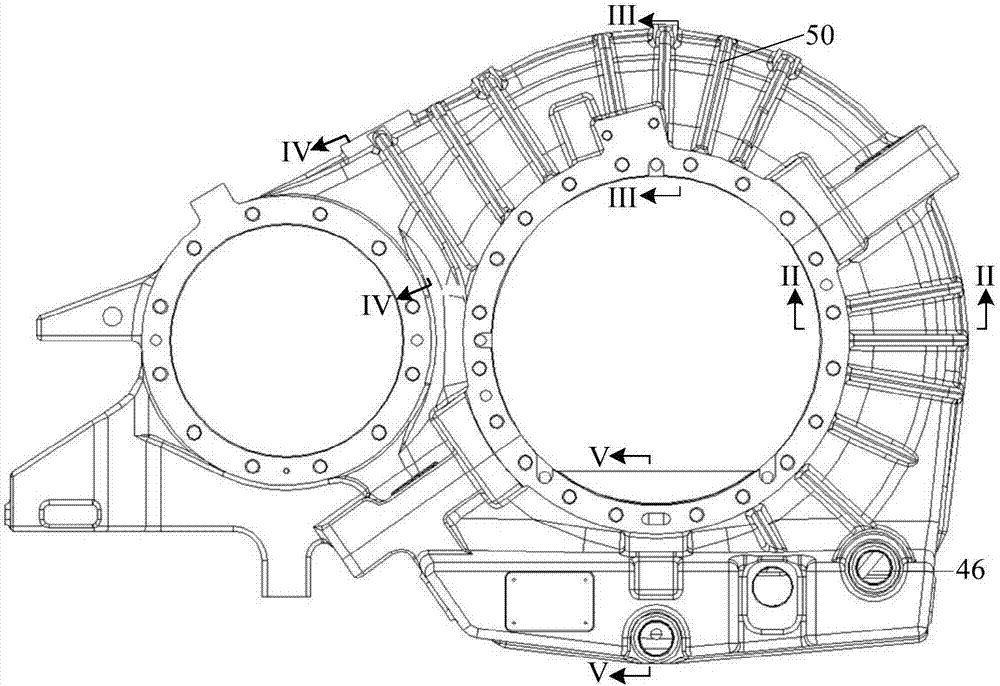

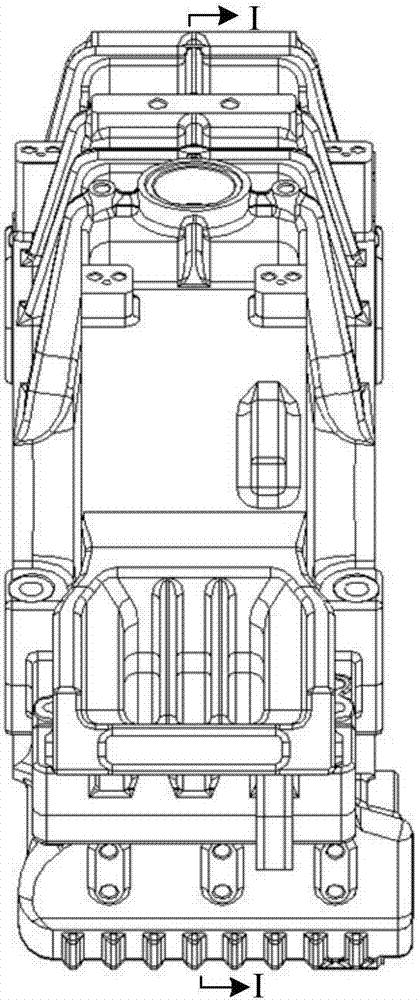

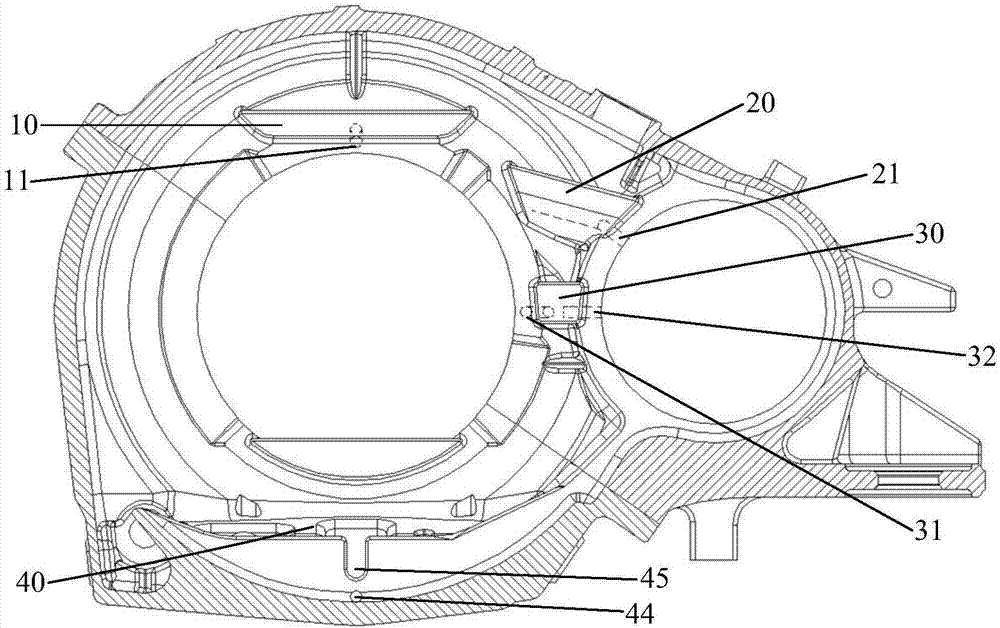

[0027] figure 1 The front view of the box body of the gear box of the rail transit vehicle provided by the present invention, figure 2 The left view of the casing of the gear box of the rail transit vehicle provided by the present invention; image 3 for figure 2 Schematic diagram of the cross-sectional structure along the I-I line, Figure 4 for figure 1 Schematic diagram of the cross-sectional structure along the line II-II. Such as Figure 1 to Figure 3 As shown, the case body of the gear box provided in this embodiment includes: an output end oil sump 10, an input end oil sump 20, a middle oil sump 30 and an oil tank 40, wherein one end of the two opposite side walls of the case body is connected to the The top of the box is trapezoidal, and the other ends of the two opposite side walls of the box are bent outward in a circular arc shape; the output oil sump 10 and the input oil sump 20 are arranged on the upper inner wall of the box, and the middle position The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com