Three-way hemispherical valve based on normal operation and online pressure maintenance of pipeline and maintenance method

A technology of normal operation and semi-spherical valves, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems that three-way semi-spherical valves cannot achieve normal operation, and achieve the effect of improving safety and reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

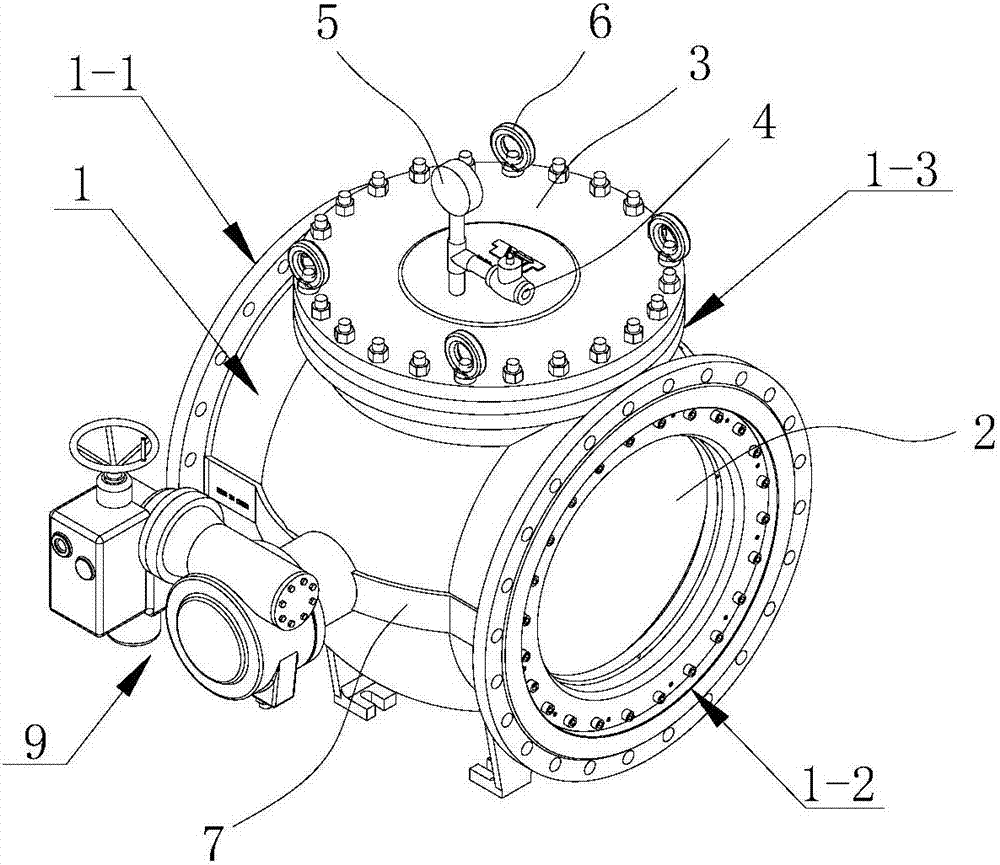

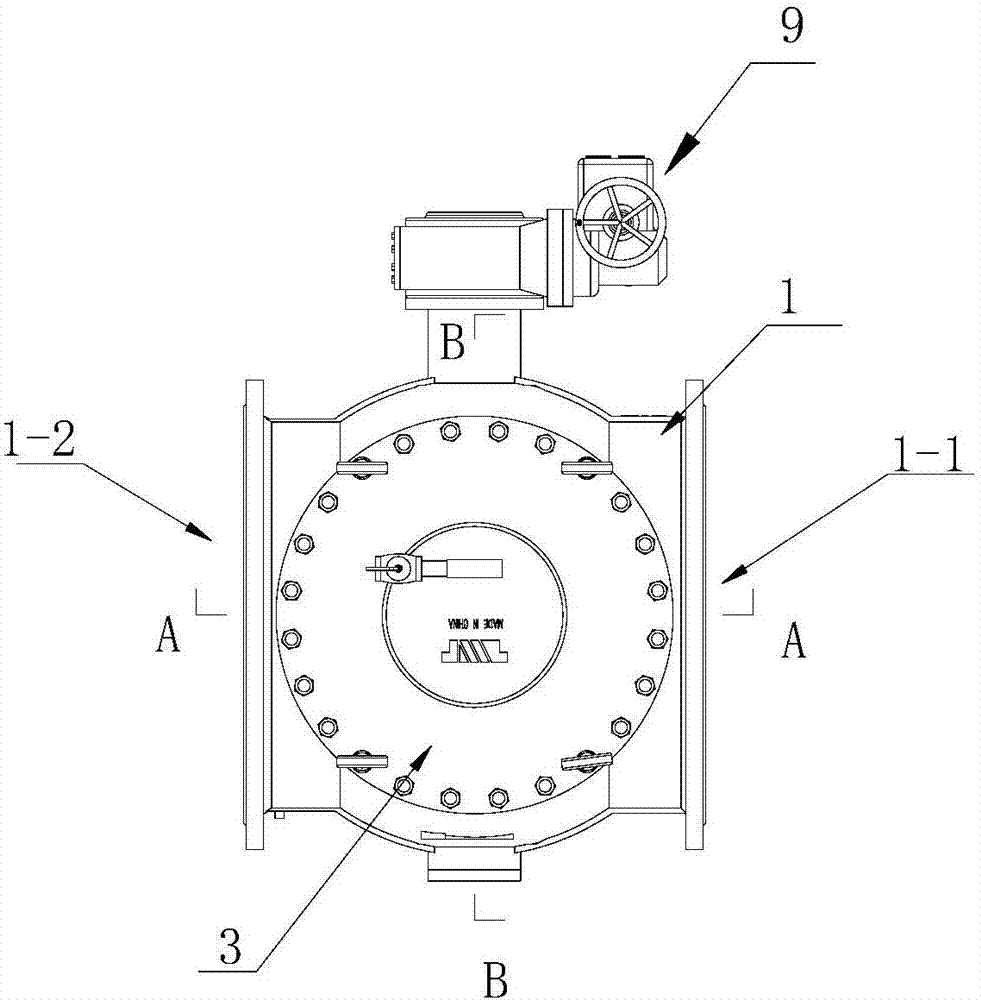

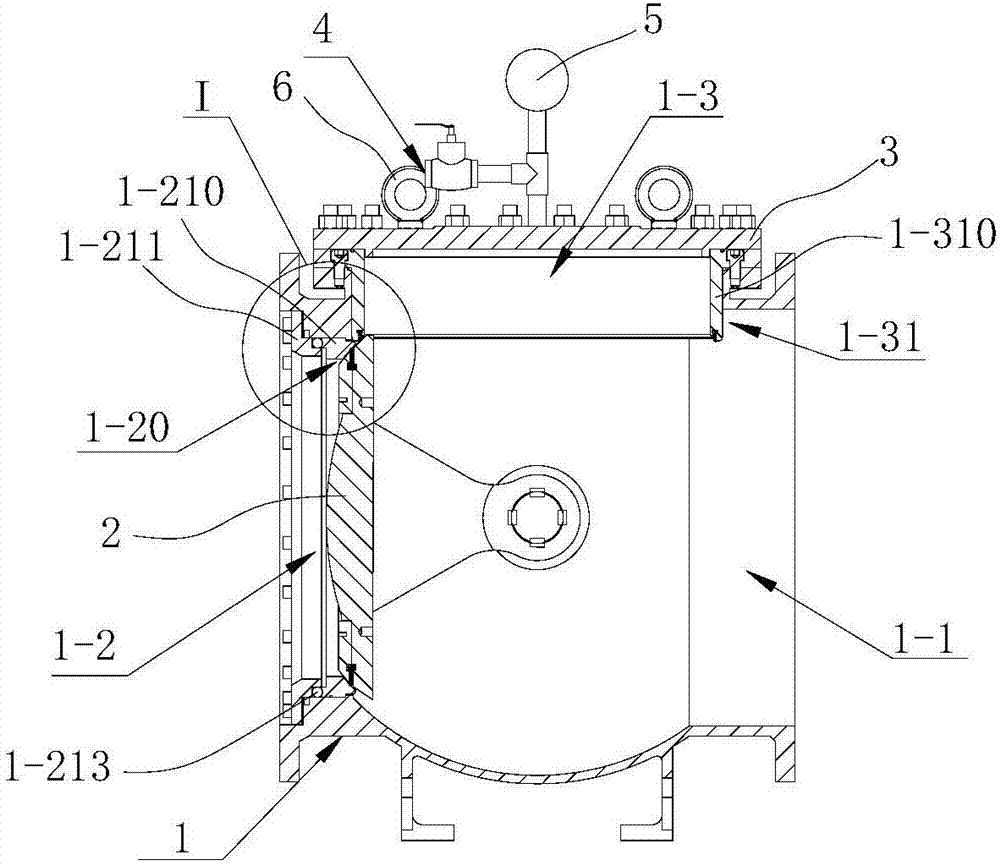

[0061] Example 1, see Figures 1 to 7 , a three-way hemispherical valve based on the normal operation of pipelines for online maintenance under pressure. The outflow channel 1-2 and the online maintenance channel 1-3; the fluid inlet channel, the fluid outflow channel and the online maintenance channel are respectively connected with the valve cavity of the valve body;

[0062] In the fluid outflow channel 1-1, there is a switch sealing pair 1-20 that cooperates with the hemispherical valve core to seal; the switch sealing pair 1-20 includes a switch static seal 1-21 and a switch dynamic seal 1-22. The switch static seal 1-21 is fixedly installed in the fluid outflow channel 1-2, and the switch dynamic seal 1-22 is installed on the hemispherical valve core 2; the switch static seal in the fluid outflow channel and the switch on the hemispherical spool The dynamic seal cooperates to form a switch seal pair; an inspection seal pair 1-30 that cooperates with the hemispherical va...

Embodiment 2

[0070] Example 2, see Figure 14 , preferably, the overhaul static seal 1-31 includes an overhaul seal seat 1-310, the overhaul seal seat is fixedly connected to the valve body 1, and an overhaul static metal sealing surface is provided at the lower end of the overhaul seal seat; An inspection dynamic seal 1-312 is provided below the switch dynamic seal, and the inspection dynamic seal 1-32 includes an inspection elastic dynamic seal 1-320, and the inspection elastic dynamic seal is installed on a hemispherical valve core; When the seal is attached to the inspection static sealing surface at the lower end of the inspection seal seat, an inspection sealing pair is formed.

[0071] Preferably in this embodiment, the maintenance elastic dynamic seal is vulcanized on the hemispherical valve core. It can also be a tire-type seal embedded on the hemispherical valve core, including a tire-type seal. The tire-type seal is provided with a pressurization compensation port. Mounting ho...

Embodiment 3

[0072] Example 3, see Figure 15 , the switch static seal 1-21 includes an outlet valve body seal seat 1-210; the outlet valve body seal seat 1-210 is welded on the valve body 1; the outlet valve body seal seat 1-210 is provided with a hemispherical The outlet metal sealing surface 1-212 matched with the switch dynamic seal on the valve core; in this way, a fixed permanent metal sealing surface is formed, thereby achieving the same life as the valve body. The outlet valve body sealing seat 1-210 is preferably tin-based bearing alloy ( Babbitt alloy), alloy steel, or hard alloy, stainless steel hard alloy, Monel alloy material. The switch dynamic seal 1-22 includes a spherical cap 1-220 installed on the hemispherical valve core through fasteners, and a switch elastic dynamic seal 1-221 is installed between the spherical crown and the hemispherical valve core; When the switch elastic dynamic seal is attached to the outlet ball sealing surface of the outlet valve body sealing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com