Method for evaluating risk of contact fatigue failure of surface hardened gear

A contact fatigue and gear technology, applied in the field of fatigue failure risk assessment of mechanical parts, can solve the problems of gear affecting reliability and service life, difficulty in gear contact fatigue analysis, affecting human-machine safety and economic benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Such as Figure 4 As shown, the sample tooth is an intermediate gear pair of a high-speed heavy-duty gearbox for a 2MW fan. In actual use, the gear pair often suffers contact fatigue damage.

[0065] The main parameters of the gear pair are as follows:

[0066]

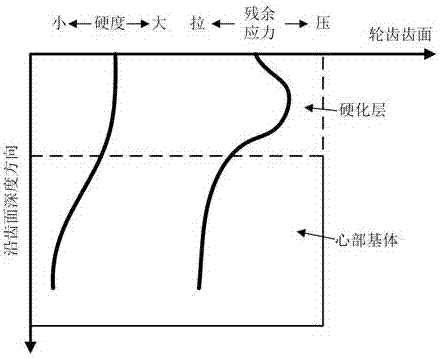

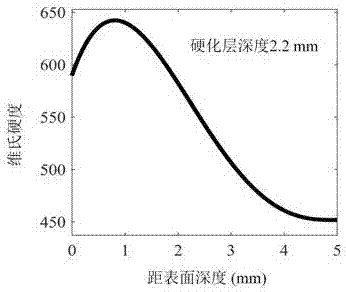

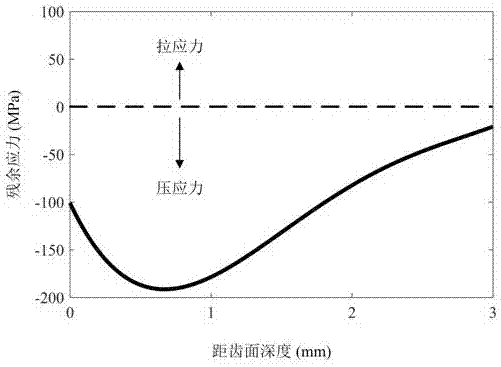

[0067] figure 1 and figure 2 The corresponding fitting function is the hardness curve and residual stress curve of this embodiment. According to the gear pair parameters of the embodiment, taking the results at the nodes on the gear meshing line as an example, the material exposure value of the gear pair contact can be gradually calculated:

[0068] Step 1. According to formula (3), get R 1 =236.28mm,R 2 =44.18mm, so the comprehensive radius of curvature of the gear pair R=37.22mm; equivalent elastic modulus E=1.15×10 11 Pa; F=1.50KN / mm; b H = 0.79 mm; p H = 1.22 GPa.

[0069] Step 2. Local Hertzian contact pressure p at the contact point dyn , calculated as follows:

[0070]

[0071] got p d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com