Stator structure and resolver

A stator and structure technology, applied in the direction of magnetic circuit shape/style/structure, winding insulation shape/style/structure, electromechanical devices, etc., can solve problems such as component deformation and reliability reduction of resolvers, and achieve reliability improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

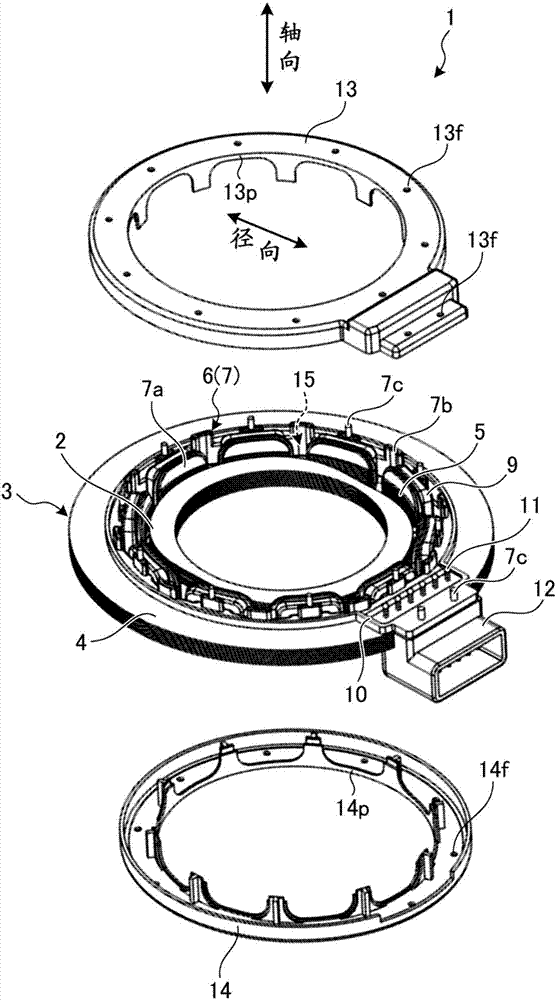

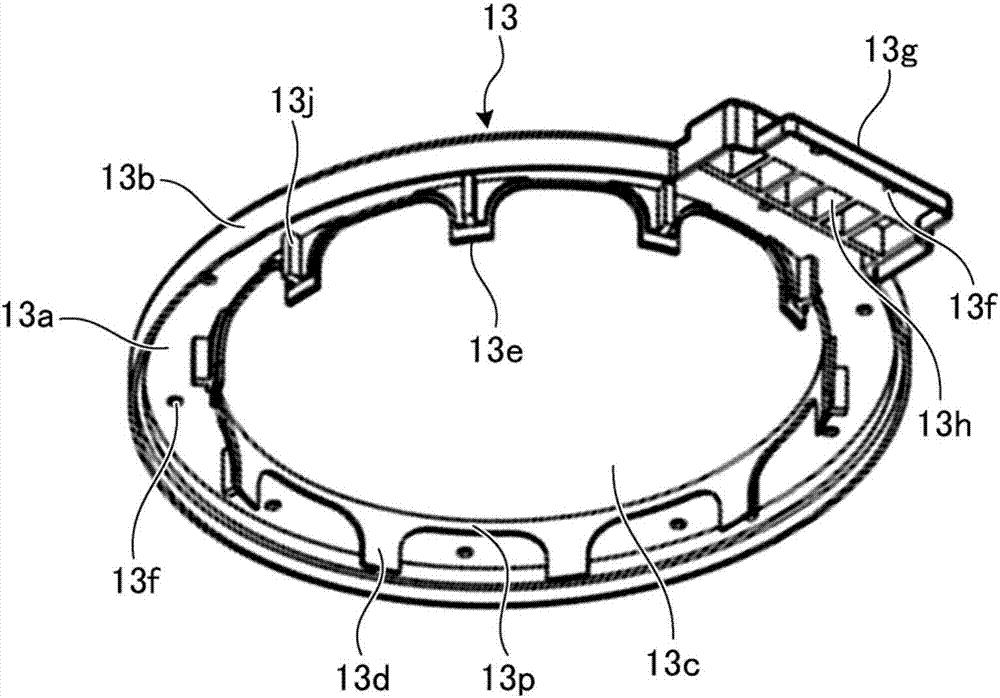

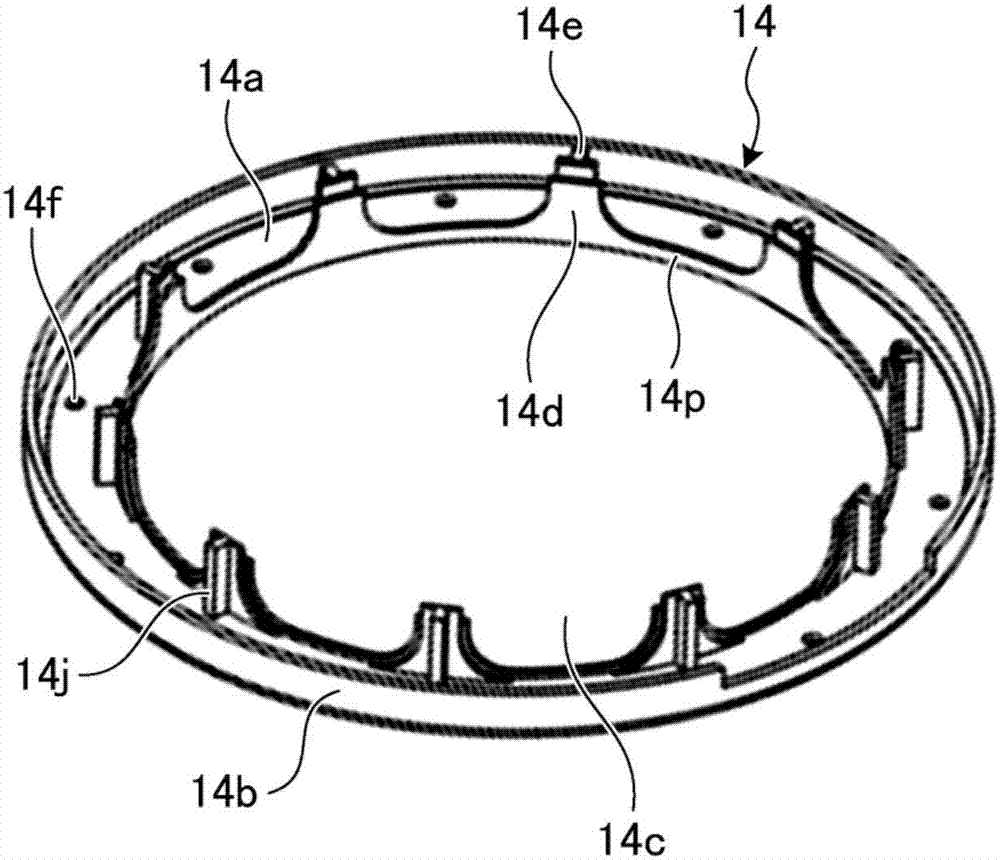

[0028] figure 1 It is a schematic exploded perspective view of the resolver related to the first embodiment. Such as figure 1 As shown, the resolver 1 of the first embodiment is a VR (variable reluctance) resolver having a rotor 2 , a stator 3 , a first coil cover 13 , and a second coil cover 14 . The stator 3, the first coil cover 13, and the second coil cover 14 constitute a stator structure.

[0029] The rotor 2 has a laminated structure in which a plurality of steel cores made of soft magnetic materials such as silicon steel plates are laminated, is attached to a rotating shaft of a motor (not shown), and is arranged inside the stator 3 . figure 1 The indicated axial direction corresponds to the axial direction of the rotation shaft of the motor connected to the rotor 2 . Additionally, if figure 1 As shown, the radial direction and the direction perpendicular to the axial direction coincide. In addition, the radial direction refers to all directions parallel to the pl...

no. 2 approach

[0063] In the second embodiment, a case where a structure in which a flange portion of an insulator and a coil cover are opposed to each other with a slight gap therebetween is applied to a resolver having a different structure from the resolver 1 of the first embodiment will be described.

[0064] Figure 11 It is a schematic exploded perspective view of the resolver of the second embodiment. in addition, Figure 12 yes Figure 11 The E-E line sectional view of the resolver shown, Figure 13 yes Figure 11 The F-F line sectional view of the resolver shown.

[0065] Such as Figures 11 to 13 As shown, the resolver 100 of the second embodiment is a VR (Variable Reluctance) resolver having a rotor 20 , a stator 30 , a first coil cover 130 , and a second coil cover 140 . The stator 30, the first coil cover 130, and the second coil cover 140 constitute a stator structure.

[0066] The rotor 20 has a laminated structure in which a plurality of steel cores made of a soft magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com