Apparatus for measuring an electric current through a bus bar

A technology for bus bars and equipment, applied in the field of current equipment, can solve the problems of complex and expensive solutions, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

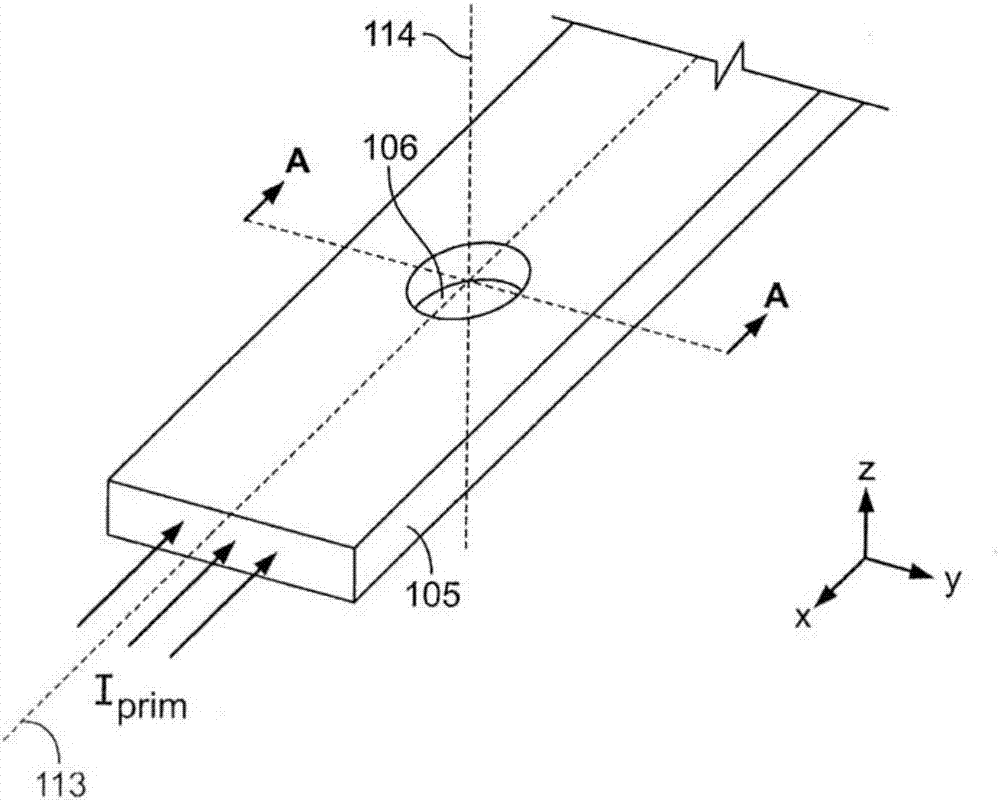

[0022] Figure 2a shows the bus bar 105 and the current I flowing through the bus bar 105 prim and the current intensity of this current is intended to be measured / determined by means of the device according to the invention. The bus bar 105 has a box shape and a longitudinal axis 113, the current I prim Transmission along longitudinal axis 113 . However, the present invention is not limited to box-shaped bus bars. Instead, it also includes other forms, such as cylindrical. The bus bar may also have a bent portion.

[0023] exist Figure 2a In the bus bar 105 shown, a cylindrical through hole 106 is arranged between the upper side and the lower side of the bus bar 105 . The axis of symmetry 114 of the through hole 106 is positioned perpendicular to the longitudinal axis 113 and intersects it. The axis of symmetry 114 is preferably also positioned perpendicularly to the upper and / or lower side of the bus bar 105 such that the through hole 106 is arranged centrally betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com