Precise and practical robot

A robotic and practical technology, applied in the field of robotics, can solve problems such as unsatisfactory production needs, uneven discharge of minced meat, complex structure of meat grinder, etc., and achieve the effect of improving automatic control rate, simple structure, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

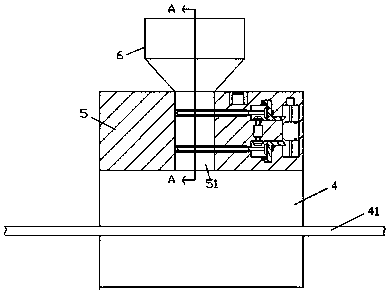

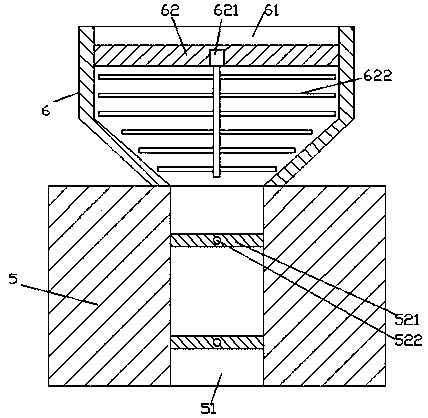

[0021] Such as Figure 1-Figure 6 As shown, a precise and practical robot of the present invention includes a fuselage 5 and a cone bucket 6 installed on the top of the fuselage 5. The inside of the fuselage 5 is provided with a vertical cavity 51, and the vertical cavity 51 The inner wall of the right side is connected with the first guide chute 52 that is equal up and down and elongated to the right. Each of the first guide slits 52 is smoothly fitted with a first guide slider 521, so A screw hole 522 is provided in the right side of the first guide slider 521, and a slide chamber 54 is provided in the fuselage 5 on the right side of each of the first guide slide grooves 52, and the slide chambers on the upper and lower sides The fuselage 5 between 54 is fixedly provided with a first electric rotating machine 57, and the upper and lower sides of the first electric rotating machine 57 are connected with a revolving shaft 571 extending outwardly. The elongated tip of the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com