Method and system for maintaining mill tensiometer

A tensiometer and tension technology, applied in the field of rolling, can solve the problems of affecting the production rhythm of the production line and delaying the production time, so as to avoid broken belts, reduce the output of belts, and ensure the production of the production line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

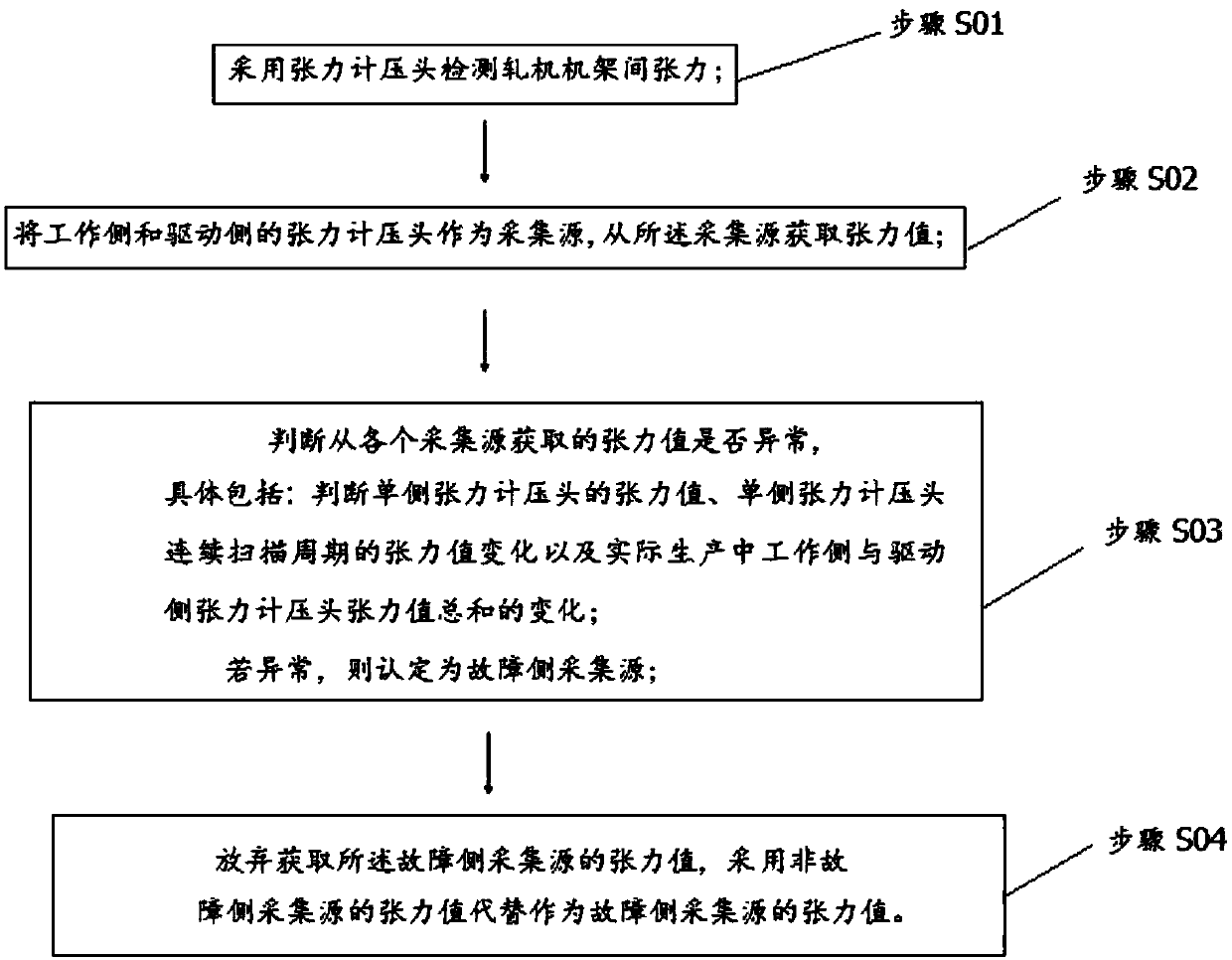

Method used

Image

Examples

Embodiment 2

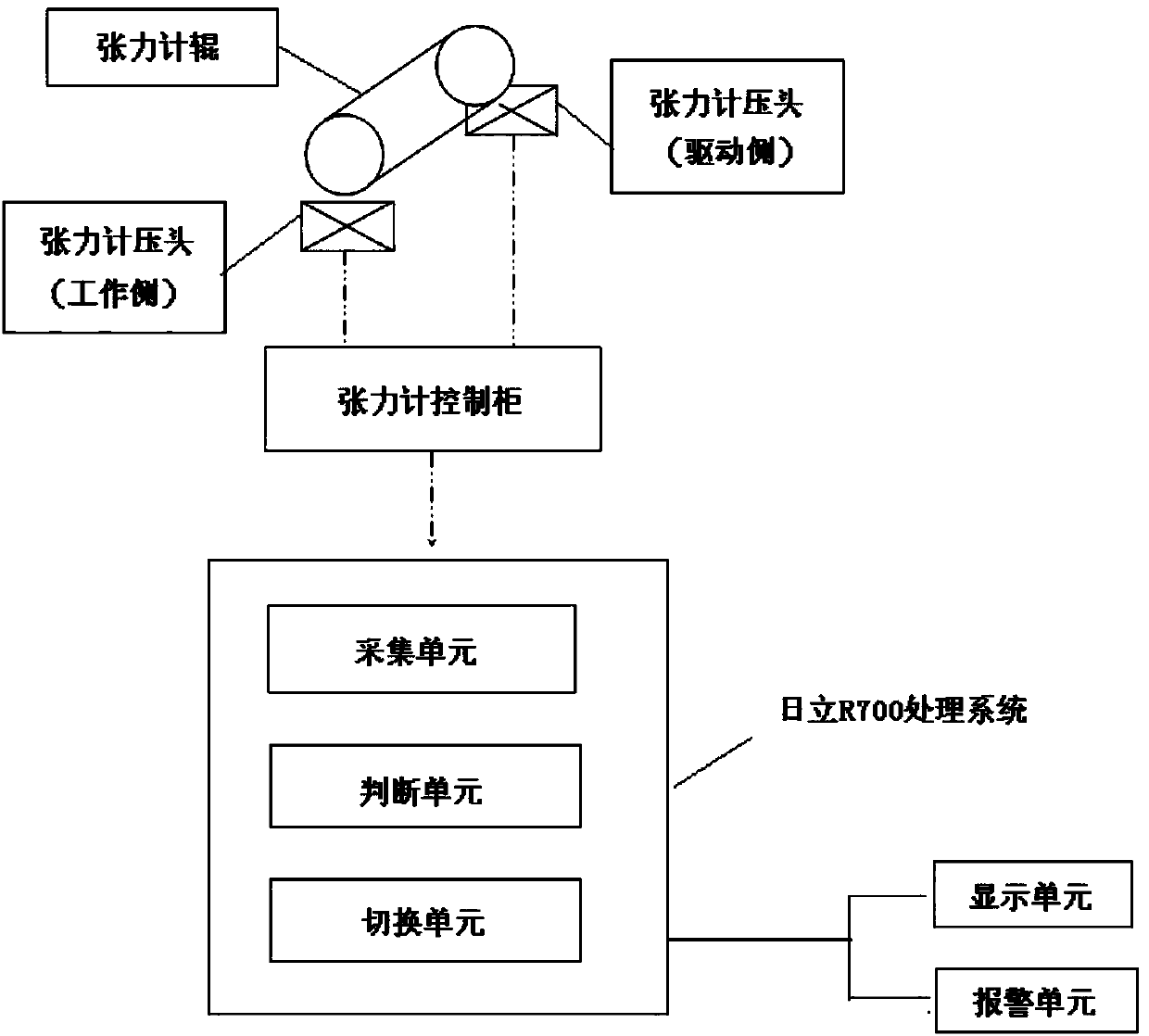

[0063] image 3 It is a schematic diagram of system communication for rolling mill tensiometer maintenance in Example 2 of the present invention. see image 3 , on the basis of the system in Embodiment 1, the system in Embodiment 2 of the present invention may further include:

[0064] The display unit is used to display the tension values obtained from each collection source and the position of the collection source with abnormal tension values;

[0065] The alarm unit is used to alarm and remind the operator that the tension value of the acquisition source is abnormal.

[0066] Specifically, each unit of the system will be described respectively below with reference to the accompanying drawings.

[0067] by image 3 Take the system of Embodiment 2 as an example, the tension value is detected by the ABB tensiometer pressure head, and transmitted to the tensiometer control cabinet, and the tensiometer control cabinet communicates with the Hitachi R700 processing system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com