Honing head capable of improving grinding precision

A honing head and honing technology, which is applied in the direction of honing machine tools, honing tools, metal processing equipment, etc., to achieve the effects of reducing frustration, reducing wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

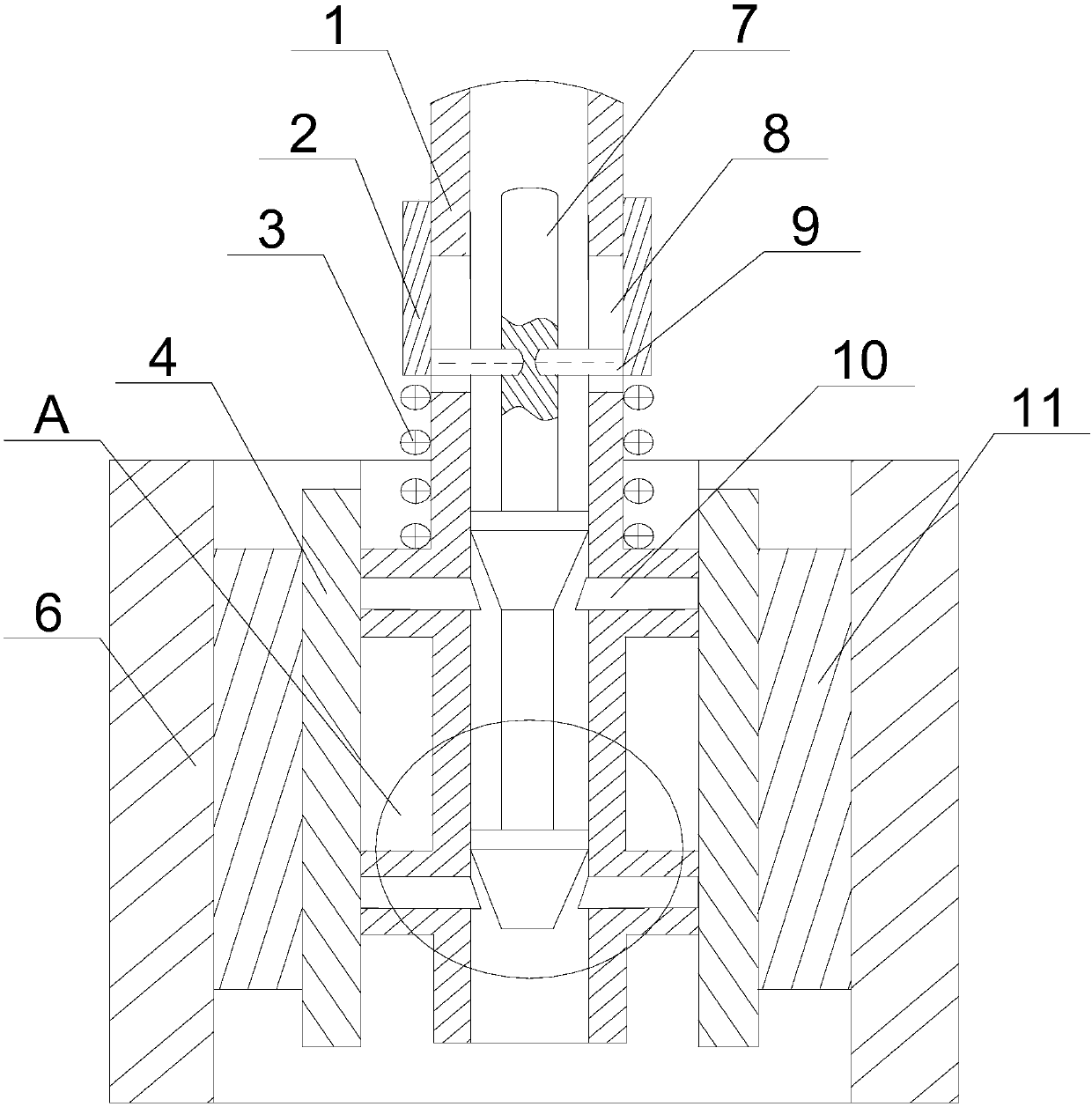

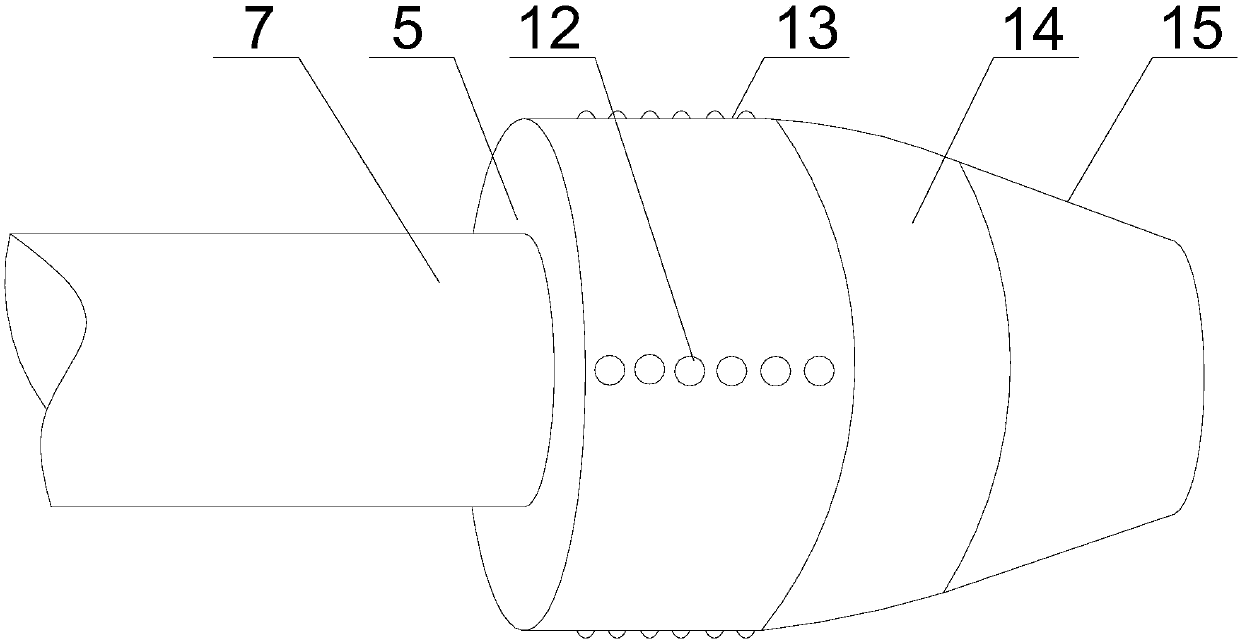

[0023] Such as figure 1 and figure 2 As shown, this embodiment includes a hollow honing body 1 and a plurality of pads 4, a plurality of transition holes are opened on both sides of the honing body 1, and adjustment pins 10 are fixed on the sides of the pads 4, and the adjustment pins 10 cooperates with the gap 14 of the transition hole, the inside of the honing body 1 is slidably provided with an adjustment rod 7, on which a plurality of protrusions 5 are mounted, and the movable end of the adjustment pin 10 is provided with a The protrusion 5 is provided with a smooth circular surface 13 and a conical surface 15, and a transitional circular surface 14 is provided at the junction of the smooth circular surface 13 and the conical surface 15; There is an adjustment hole 8, and an adjustment nut 2 is threaded on the outer wall of the honing body 1, and a pin 9 is fixed on the adjustment nut 2, and the pin 9 passes through the adjustment hole 8 and is connected with the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com