High-precision machining method for valve element of floating ball type drain valve

A processing method, floating ball technology, applied in metal processing equipment, manufacturing tools, honing tools, etc., can solve the unqualified airtightness of the valve core and valve seat, the difficulty of ensuring coaxiality, and the reduction of the trap assembly yield, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

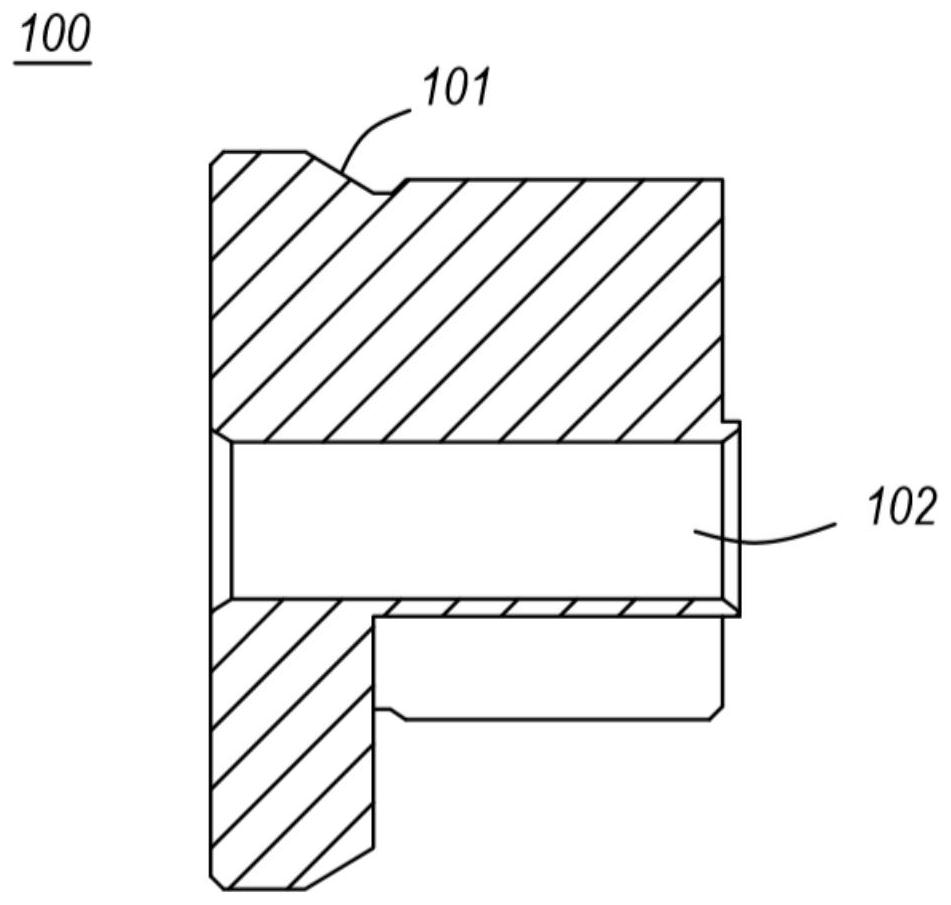

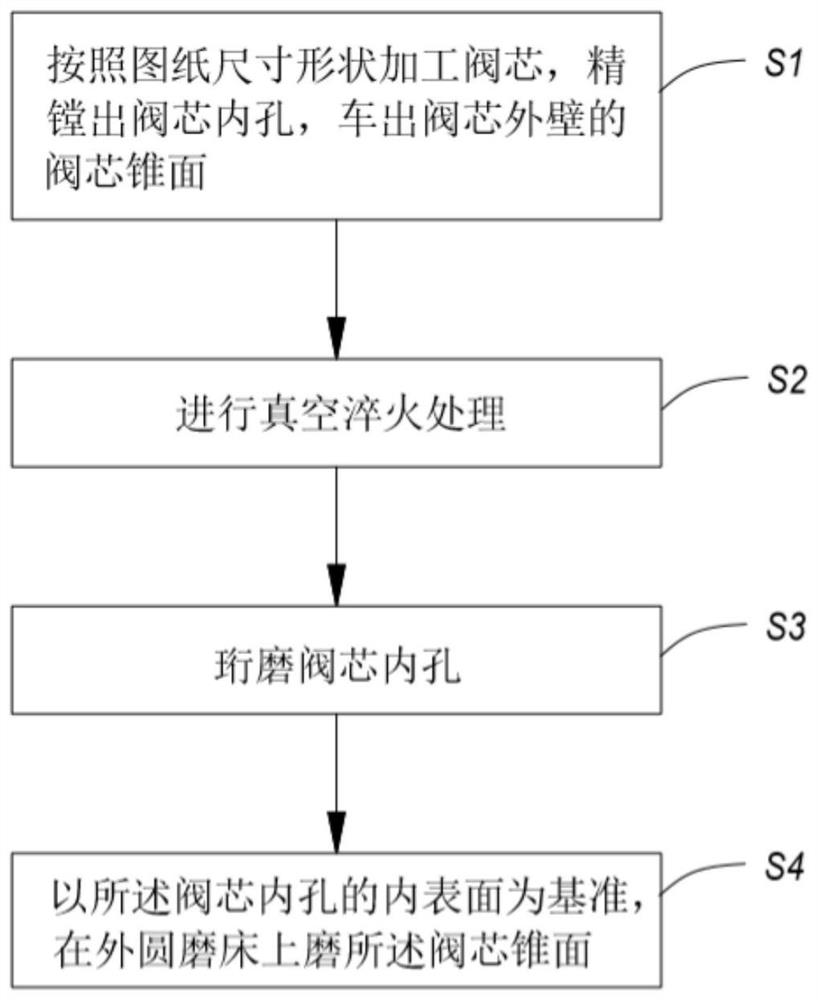

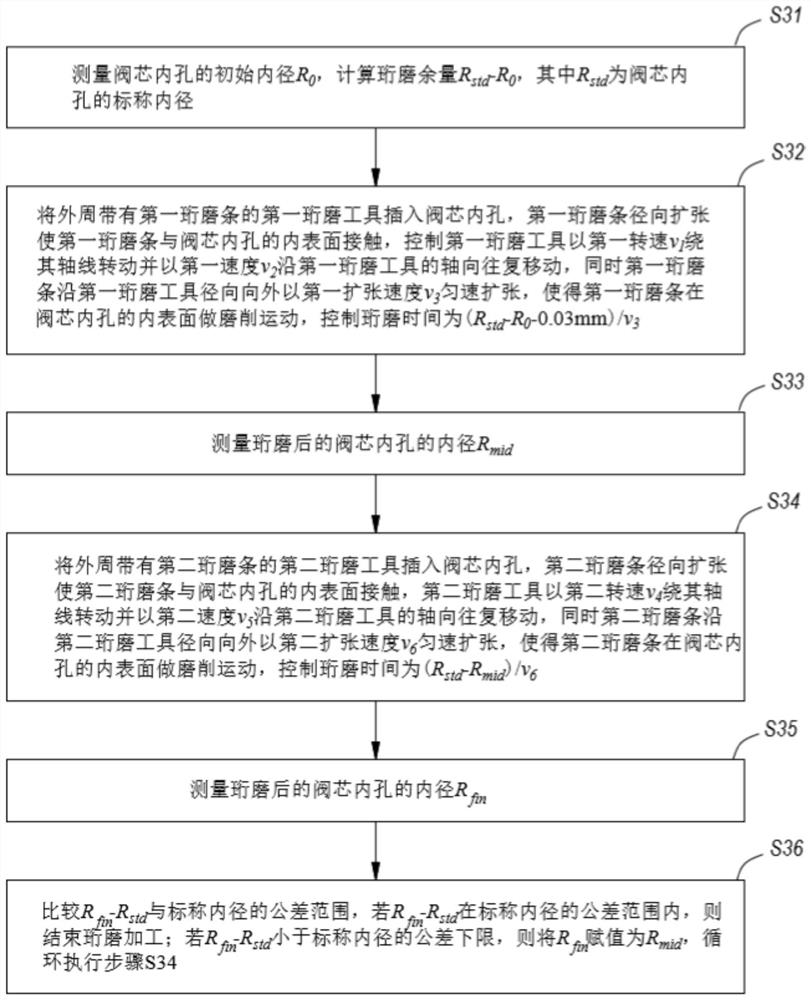

[0032] The processing of the spool 100 is relatively difficult, so the spool becomes a bottleneck restricting the assembly quality of the high-end double-spool steam trap. In the traditional process, after the inner hole of the valve core is finely bored, quenching treatment is performed, and then the taper surface 101 of the valve core is directly grinded on the cylindrical grinder. Generally speaking, the hardness of the spool after quenching is required to be HRC54-56 degrees. The spool 100 has a special-shaped structure, and the minimum wall thickness of the inner hole 102 of the spool is uneven, and the minimum wall thickness reaches 0.5 mm; the diameter of the inner hole 102 of the spool is very small, not exceeding 6 mm. Further studies have found that such a valve core with a small size and special-shaped structure is easily deformed after quenching,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com