Well cementation and fracturing modular assembling system and using method thereof

A modular, loading and unloading system technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., to reduce the number of purchases, improve matching performance, and facilitate replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

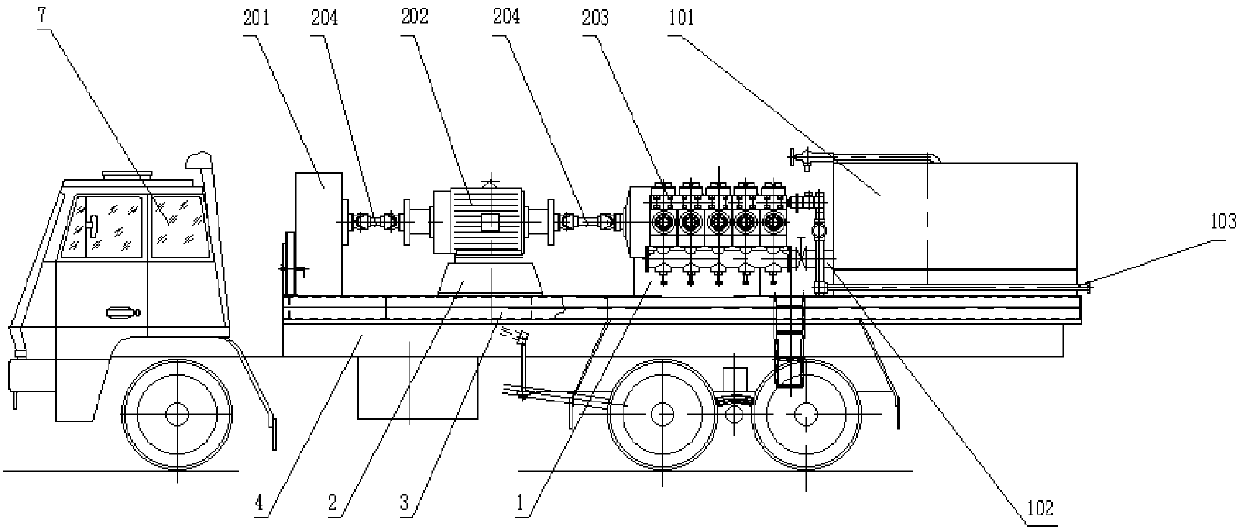

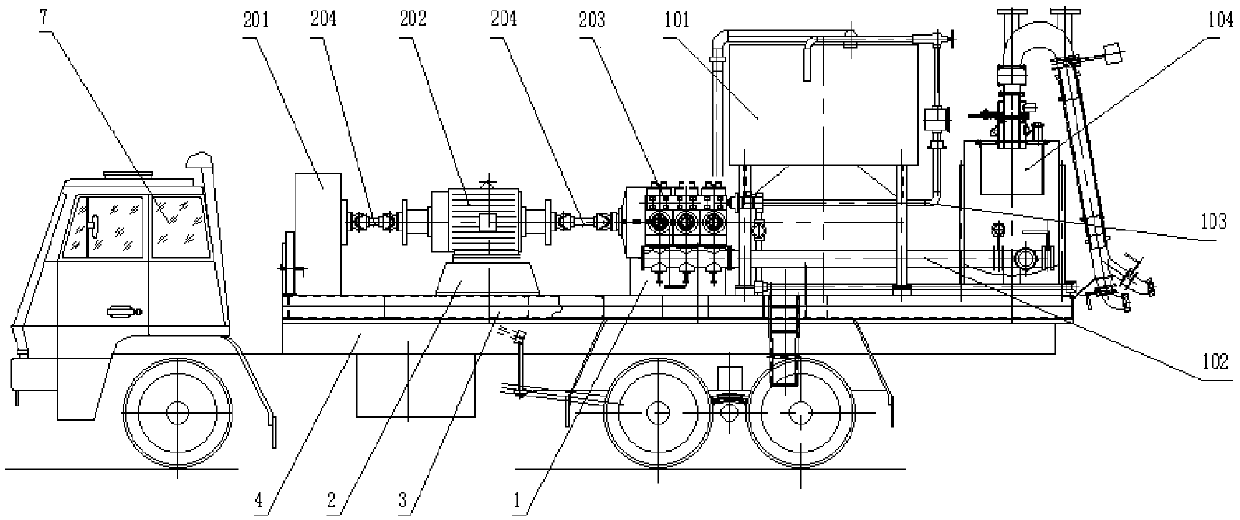

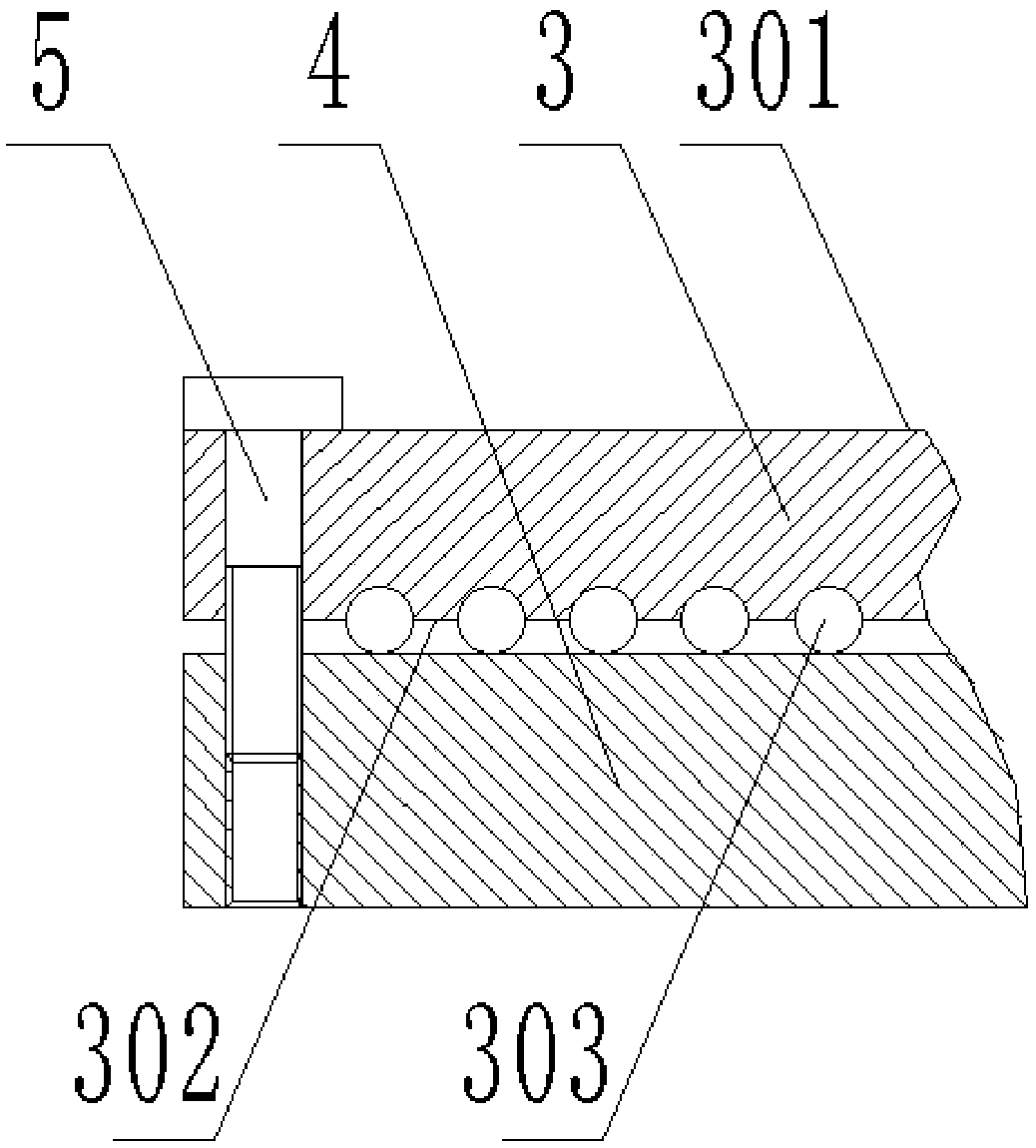

[0039] A modular loading and unloading system for cementing and fracturing, including a functional module 1, a driving mechanism 2 and a module assembly plate 3; the functional module 1 includes a water tank 101, a suction pipeline 102, a discharge pipeline 103 and a concrete mixing tank 104; The driving mechanism 2 includes a driving gear box 201, a motor 202 and a pump group 203; the module assembly plate 3 is spliced by a plurality of plates, and each plate is connected with a water tank 101, a concrete mixing tank 104, a driving gear box 201, and a motor 202 One of them and the pump group 203 form an assembly unit, and the assembly unit is spliced into one.

[0040] The functional module 1 is divided into a fracturing actuator and a cementing actuator. The fracturing actuator includes a water tank 101, a suction pipeline 102, and a discharge pipeline 103. The cementing actuator includes a water tank 101, a suction pipeline 102, and a discharge pipe. road 103 and concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com