Dough kneading equipment for quickly producing dough

A dough and fast technology, applied in the direction of dough homogenization, dough extruder, baking, etc., can solve the problem of low dough efficiency, achieve the effect of improving production efficiency, simple structure, and improving gluten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

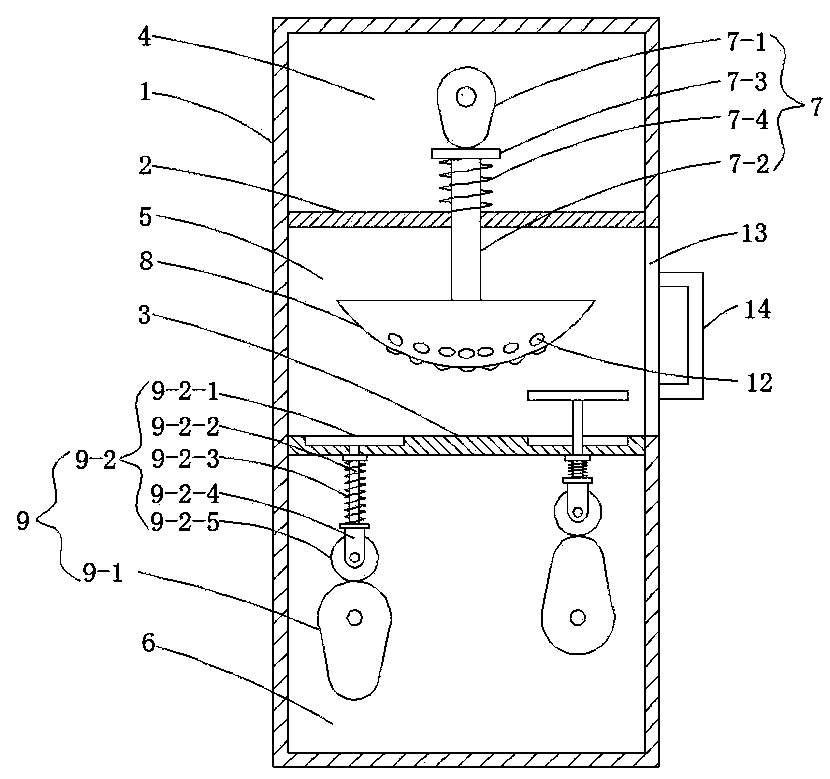

[0022] Such as Figure 1 to 3 As shown, this embodiment provides a kneading device for quickly making dough, which includes a box body 1 in which a baffle 2 and a baffle 3 are sequentially arranged from top to bottom. The baffle 2 and the baffle 3 connect the box The body 1 is divided into upper transmission chamber 4, extrusion chamber 5, and lower transmission chamber 6 from top to bottom. A cam transmission mechanism 7 is provided in the upper transmission chamber 4, and the cam transmission mechanism 7 includes a cam 7-1 and a cam 7. -1 below the push rod 7-2 that penetrates the baffle 2, the top of the push rod 7-2 is provided with a stop 7-3 that cooperates with the cam 7-1, and a winding is provided between the stop 7-3 and the baffle 2. The compression spring 7-4 on the push rod 7-2, the bottom of the push rod 7-2 is provided with an extrusion hammer 8 located in the extrusion chamber 5, and the lower transmission chamber 6 is provided with two cam transmission mechanis...

Embodiment 2

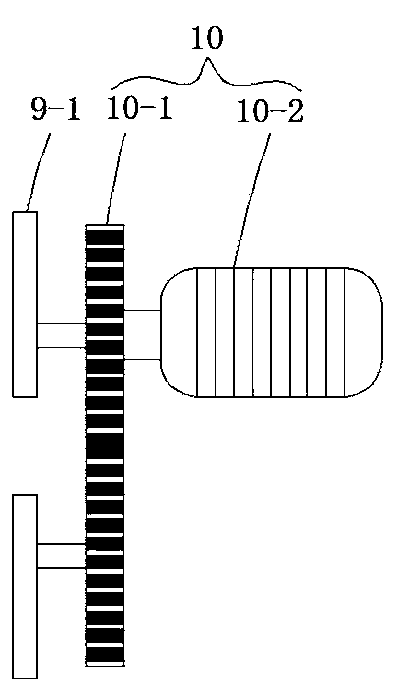

[0025] Such as figure 1 with 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the two cams A9-1 are connected to the same driving mechanism 10, and the driving mechanism 10 includes a gear set 10-1, The gear set 10-1 is composed of two identical gears respectively connected to the corresponding cam A9-1, and one of the gears is connected to the driving motor 10-2.

[0026] In this embodiment, the gear connected to the driving motor drives the other gear to rotate. The two gears are the same, ensuring that the cam A corresponding to the gear can rotate at a constant speed, so that the ejection mechanism corresponding to the cam A moves up and down rhythmically .

Embodiment 3

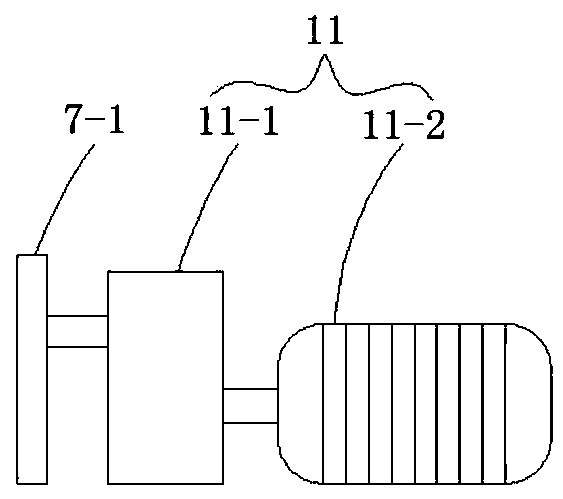

[0028] Such as figure 1 with 3 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the cam 7-1 is connected with a driving device 11, and the driving device 11 includes a reduction box 11 connected with the cam 7-1. 1. The gearbox 11-1 is connected with a motor 11-2.

[0029] The lower end surface of the squeeze hammer 8 is set as a spherical surface, and a number of uniformly distributed protrusions 12 are provided on the spherical surface.

[0030] The squeezing chamber 5 is provided with a box door 13 and a handle 14 is provided on the box door 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com