Mixing method for hydrolytic sensitive high polymer material and modified assistant and blender mixer

A technology of high polymer and mixer, applied in mixers, mixers, chemical instruments and methods with rotary stirring devices, etc., can solve the problems of feeding difficulties in the feeder, avoid feeding difficulties, and achieve excellent product performance. The effect of avoiding material agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A mixing method of a hydrolysis-sensitive polymer material and a modification aid in this embodiment includes step A: adding the modification aid and a hydrolysis-sensitive polymer material with heat after drying as materials to be mixed to the mixing In the mixer, the material to be mixed is stirred and mixed through the mixing mechanism of the mixer; during the mixing and mixing process, the dry gas is passed into the mixer to replace the air in the mixer, so that the material in the mixer is in a dry state. Stirring and mixing are carried out in the atmosphere, and at the same time, the heat exchange layer of the mixer performs heat exchange with the materials in the mixer to reduce the temperature of the materials in the mixer.

[0033]When the mixing method of the present invention is used to mix the hydrolysis-sensitive polymer material and the modification additive, since the material of the mixer is stirred and mixed in a dry atmosphere, the situation that the ma...

Embodiment 2

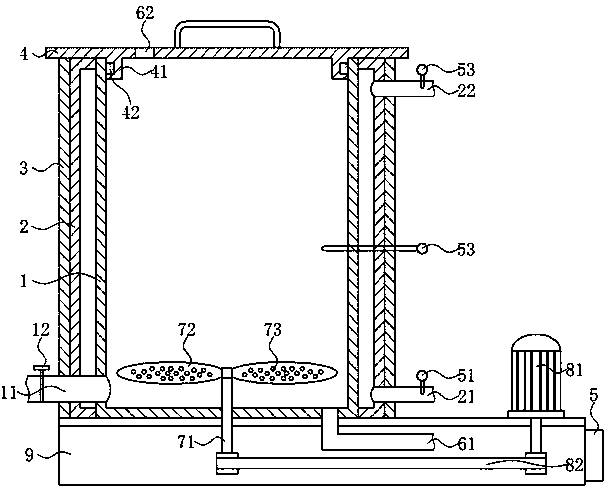

[0039] Such as figure 1 As shown, a mixing machine for hydrolysis-sensitive polymer materials and modification additives in this embodiment includes a cylinder body 1 and a detachable cylinder head 4 assembled on the top of the cylinder body 1, and the lower part of the cylinder body 1 A discharge port 11 is provided, an air inlet 61 is provided at the lower part of the cylinder body 1, an air outlet 62 is provided on the upper side of the cylinder body 1 or / and the cylinder head 4, a heat exchange layer is arranged outside the cylinder body 1, and the cylinder body 1 is equipped with a stirring mechanism.

[0040] When adopting the mixer of the present invention to carry out the mixing operation of the hydrolysis-sensitive polymer material and the modification auxiliary agent, feed dry gas into the mixer from the air inlet 61 to replace the air in the mixer, and the air will flow from The air outlet 62 is discharged, and the cylinder head 4 is opened from the top of the cyli...

Embodiment 3

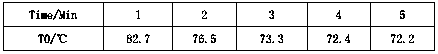

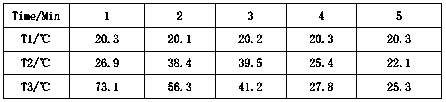

[0052] Such as figure 1 As shown, based on the combined design of the technical features of Embodiments 1 and 2, this embodiment applies the present invention to the modification of hydrolysis-sensitive polymer materials for experimental comparison. Wherein, the inner diameter D of the cylinder body 1 is 40cm, the depth H in the cylinder body 1 is 50cm, and the height h of the third temperature sensor 53 relative to the inner bottom surface of the cylinder body 1 is 25cm. At this time, the volume of the cylinder body 1 is about 60L . The discharge port 11 of the mixer is connected with the feeder of the twin-screw extruder (not shown), so as to realize the modification process of the hydrolysis-sensitive polymer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com