High precision tool carrier

A tool carrier, high-precision technology, applied in the direction of manufacturing tools, wire tensioning appliances, etc., to reduce processing costs, reduce customer risks, and reduce failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

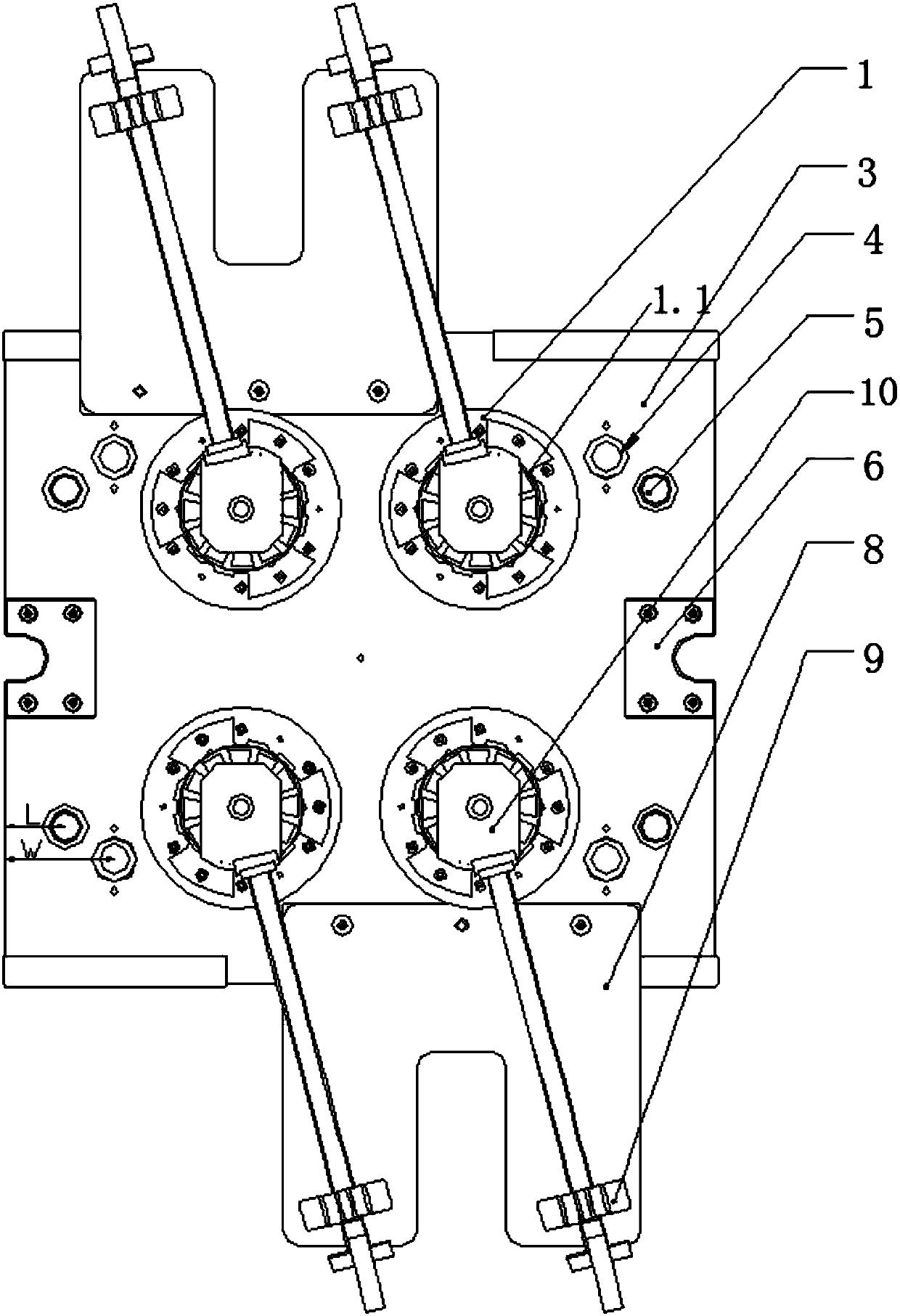

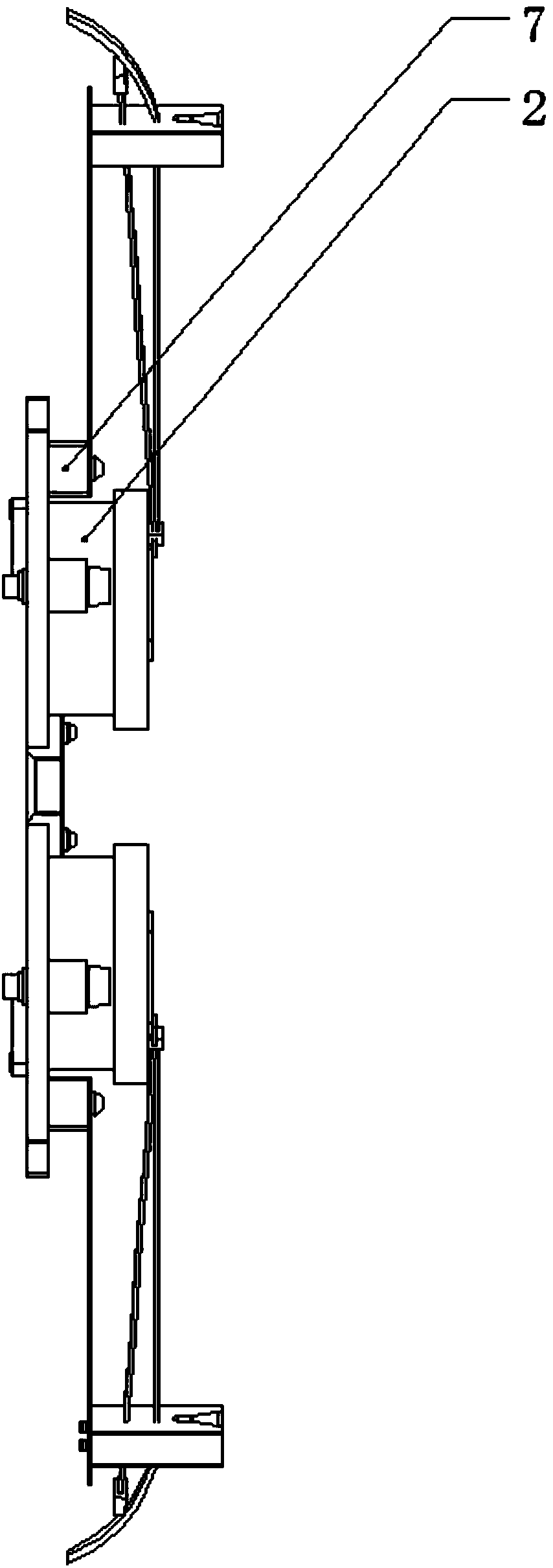

[0017] Such as Figure 1-2 Shown: a kind of high-precision tool carrier, is characterized in that, comprises

[0018] Fixture 1, fixture substrate 3, fixture pad 2, positioning pin bushing 4, high-precision positioning pin 5, product blocking protection block 6, wiring harness substrate 8, wiring harness pad 7 and wiring harness block 9;

[0019] The jig substrate has a rectangular structure, and four jigs 1 are evenly arranged up, down, left, and right along the center on the jig substrate. The jig is a cylindrical structure with a product placement groove 1.1 on the upper end. The bottom is fixed with the jig substrate by the jig cushion block, and the product 10 is placed in the jig placement groove, and the jig placement groove is circular; the end of each product is fixed by a wiring harness block, and the wiring harness block is installed vertically on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com