Banana slicer for food processing

A technology of slicing device and food processing, applied in metal processing and other directions, can solve the problems of waste, influence of drying operation, unfavorable automatic production, etc., and achieve the effect of simple structure and improved slicing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

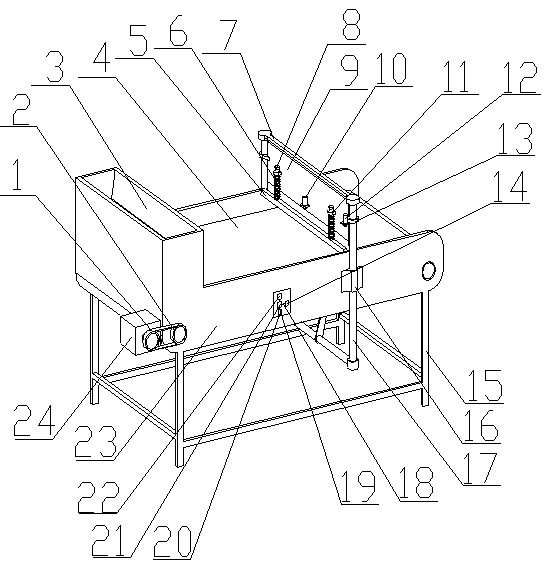

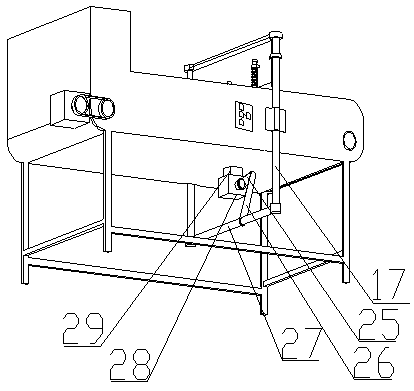

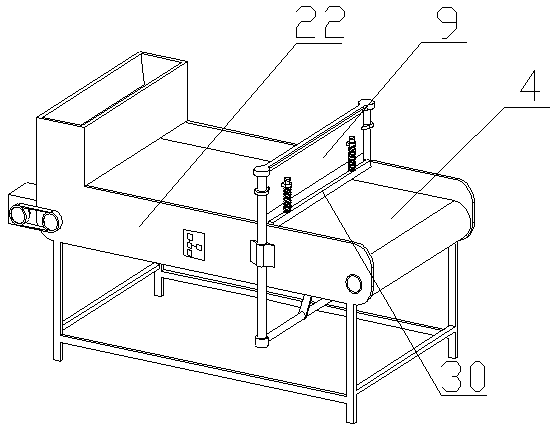

[0027] A kind of food processing banana slicing device of the present invention is realized in this way, during use, when banana is sliced, at first hopper 3 mouthfuls are connected with external feeder, and bananas are dropped into hopper 3 one by one, then Fall on the transmission belt 4 one by one, drive the motor 2 to work, the motor shaft rotates, and drive the connected cylinder 2 to rotate through the transmission belt 1, the cylinder 2 drives the transmission belt 4 to rotate, and then the bananas on the transmission belt 4 are transmitted, and, Fixed motor 28 works, and the motor shaft of fixed motor 28 drives active plate 25 to rotate, and active plate 25 drives drive plate 26 to rotate, and then drive plate 26 drives fixed bar 27 to move up and down, when one end of drive plate 26 rotates to highest point, fixed The position of the rod 27 is the lowest, and when one end of the drive plate 26 moves to the lowest point, the position of the fixed rod 27 reaches the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com