Table vinegar preparation method and system

A technology of pouring vinegar and vinegar grains, which is applied in the field of vinegar preparation, can solve the problems of insufficient leaching and microbial contamination in three-draining water storage, and achieve the effects of less residual acetic acid, saving equipment investment, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

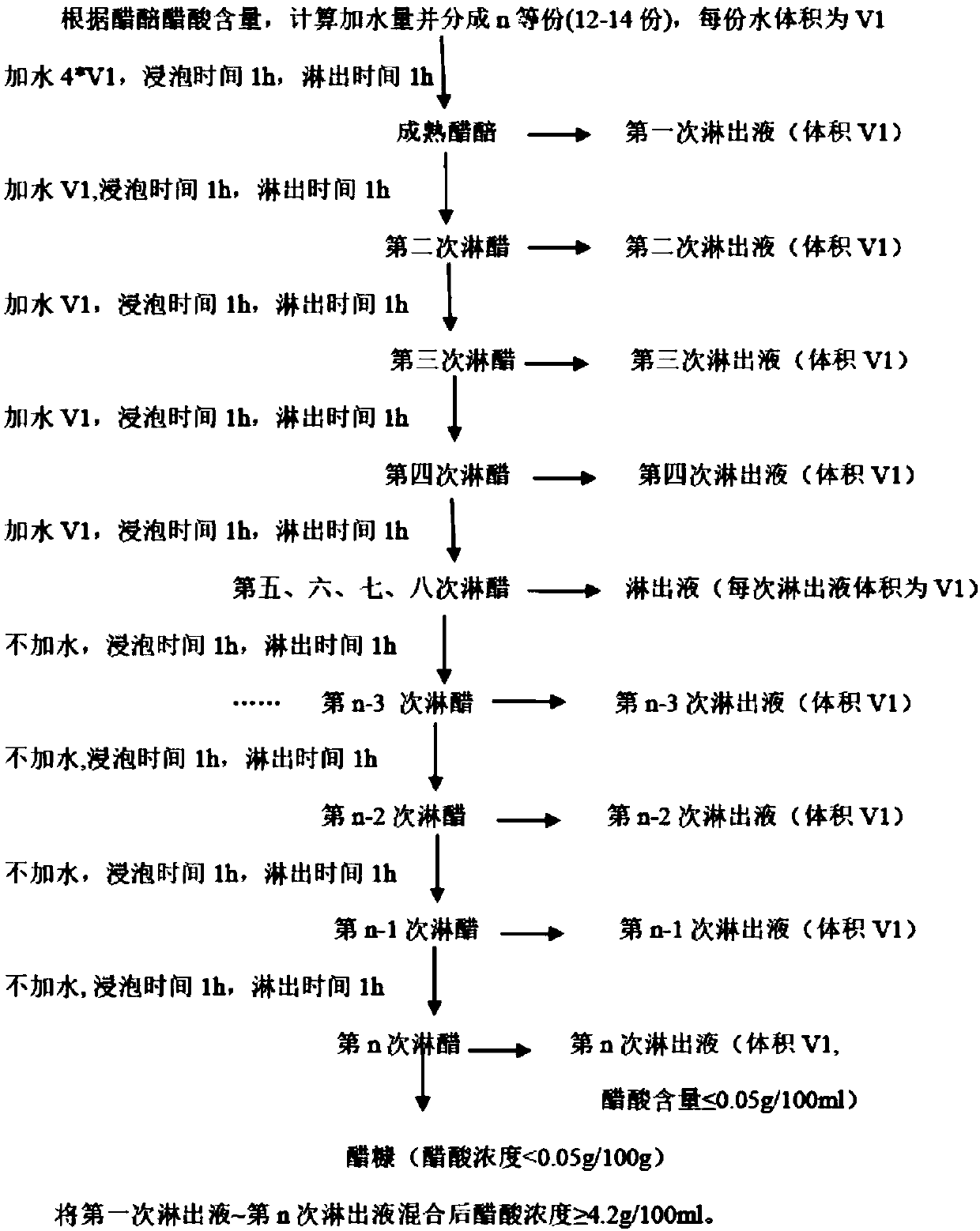

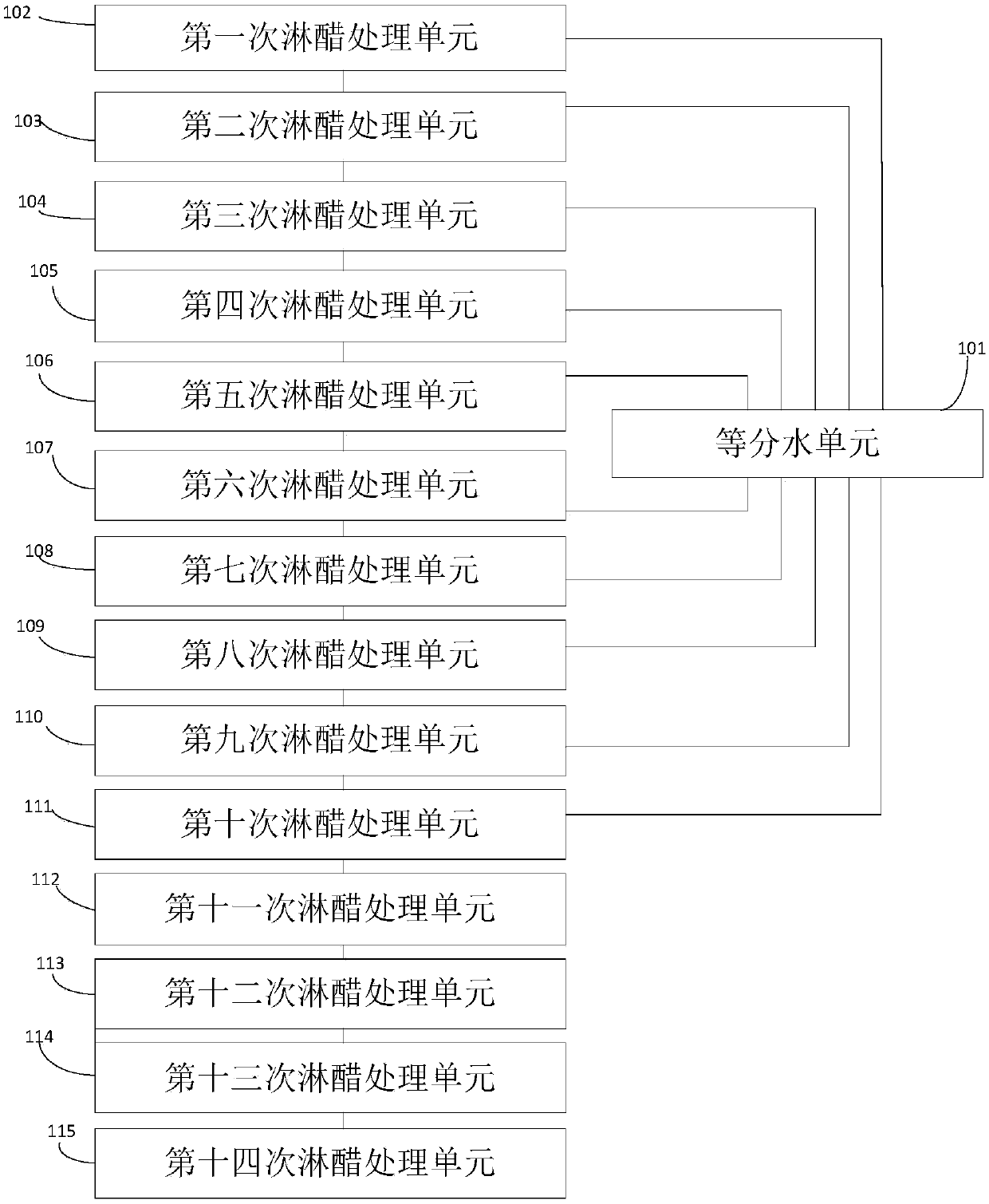

[0056] It is known that the acetic acid content of mature vinegar grains is 6.5%, the weight is 20t, the total acid content of the output vinegar liquid is 4.2g / 100mL, the moisture content of vinegar bran is 65%, and the weight is 18.2t. The content of acetic acid is 0.01g / 100g, the total amount of water added is 41441L,

[0057] 1. Calculate the amount of water added and divide it into 12 equal parts. The volume of each part of water is V1, V1=3453L;

[0058] 2. The first vinegar drenching treatment: add water 4*V1 (13814L), soak for 1 hour, leaching for 1 hour, the leaching liquid is V1,

[0059] 3. The second to eighth vinegar drenching treatment: add water V1 each time, soak for 1 hour, and leaching for 1 hour. The leaching liquid is V1 each time.

[0060] 4. The ninth to twelfth times of vinegar drenching treatment: do not add water each time, soak for 1 hour, leaching for 1 hour, each time the leaching liquid is V1,

[0061] 5. Mix the first leachate to the twelfth lea...

Embodiment 2

[0064]It is known that the acetic acid content of mature vinegar grains is 7.0%, and the weight is 25t. The total acid content of the output vinegar liquid is 5.0g / 100mL. The content of acetic acid is 0.02g / 100g, the total amount of water added is 49088L,

[0065] 1. Calculate the amount of water added and divide it into 13 equal parts. The volume of each part of water is V1, V1=3776L;

[0066] 2. The first vinegar drenching treatment: add water 4V1 (15104L), soak for 1 hour, leaching for 1 hour, the leaching liquid is V1,

[0067] 3. The second to ninth times of vinegar drenching treatment: add water V1 each time, soak for 1 hour, and leaching for 1 hour. The leaching liquid for each time is V1,

[0068] 4. The tenth to thirteenth times of vinegar drenching treatment: do not add water each time, soak for 1 hour, and leaching for 1 hour. The leaching liquid for each time is V1,

[0069] 5. Mix the first leachate to the thirteenth leachate, the total acid (in terms of acetic ...

Embodiment 3

[0072] It is known that the acetic acid content of mature vinegar grains is 7.5%, the weight is 30t, the total acid content of the output vinegar liquid is 6.0g / 100mL, the moisture content of vinegar bran is 70%, and the weight is 27.3t. The content of acetic acid is 0.03g / 100g, and the total amount of water added is 54231L.

[0073] 1. Calculate the amount of water added and divide it into 14 equal parts. The volume of each part of water is V1, V1=3874L;

[0074] 2. The first vinegar drenching treatment: add 4*V1 (15494L), soak for 1 hour, leaching for 1 hour, the leaching liquid is V1,

[0075] 3. The second to tenth times of vinegar drenching treatment: add water V1 each time, soak for 1 hour, leaching for 1 hour, each time the leaching liquid is V1,

[0076] 4. The eleventh to fourteenth vinegar drench treatment: do not add water each time, soak for 1 hour, leached for 1 hour, and each time the leaching liquid is V1,

[0077] 5. Mix the leachate for the first time to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com