Zone-controlled large-scale soaking pit furnace

A zone control and soaking furnace technology, applied to heat treatment furnaces, furnaces, furnace types, etc., to achieve the effects of ensuring temperature uniformity, good dynamic response, and improving heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

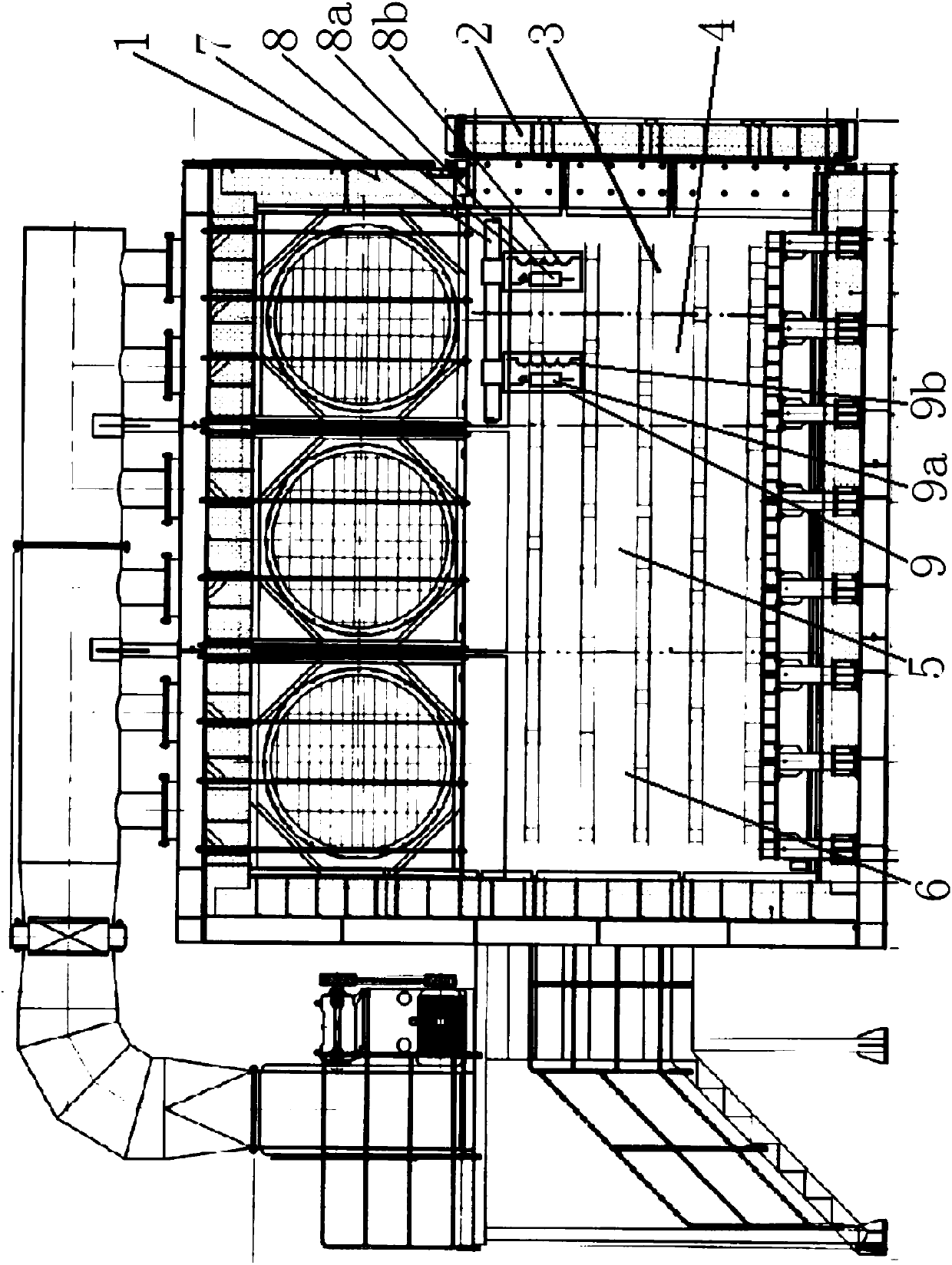

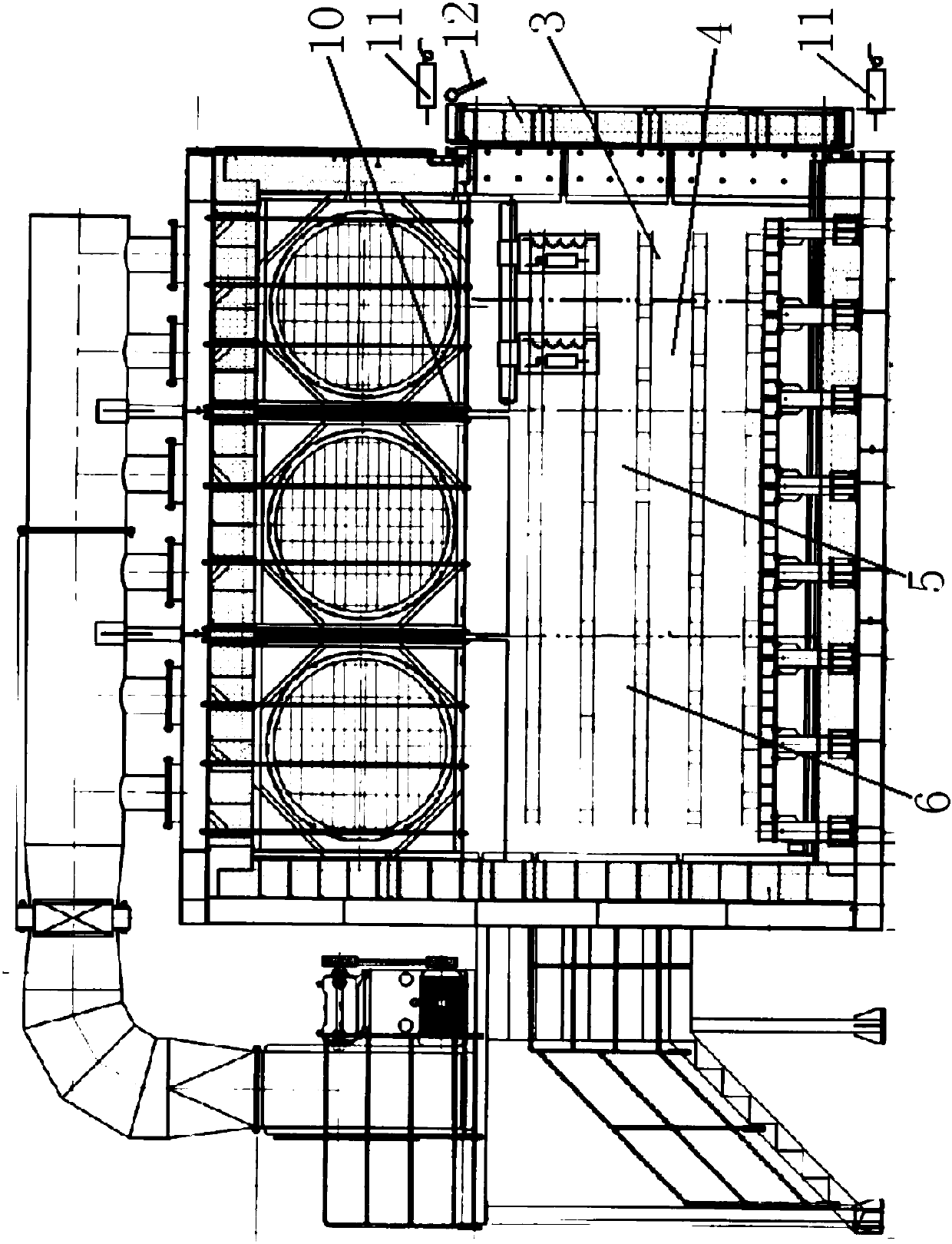

[0031] In order to achieve the purpose of the present invention, a large-scale soaking furnace with partition control includes: the soaking furnace is divided into the first partition 3, the second partition 4, and the third partition along the direction perpendicular to the furnace door 2 plane to the furnace. 5. The fourth partition 6, the width of the third partition 5 and the fourth partition 6 are equal, the width of the first partition 3 and the second partition 4 is equal to the width of the third partition 5; the first partition 3 has the first temperature control Module 8, the second partition 4 has a second temperature control module 9; the first temperature control module 8 has a first temperature sensing element 8a, a first heater 8b, and the second temperature control module 9 has a second temperature sensing element 9a, a second temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com