Automatic winding machine for sewing machine

An automatic thread winding and sewing machine technology, which is applied in the direction of bobbin winding in sewing machines, sewing equipment, sewing machine components, etc., can solve the problems of easy thread falling off, difficult to become larger, easy to be pulled off, etc., and achieve the effect that it is not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

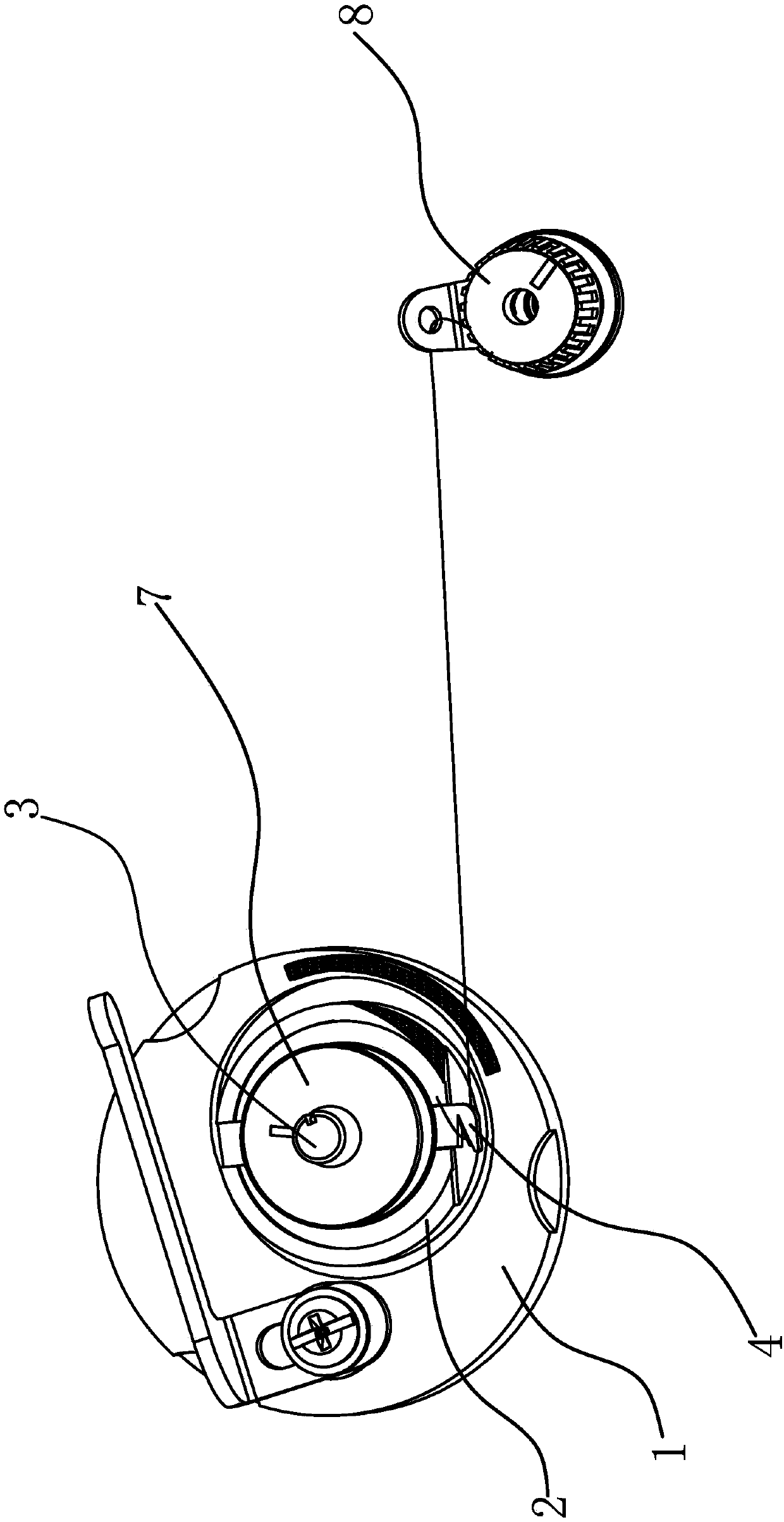

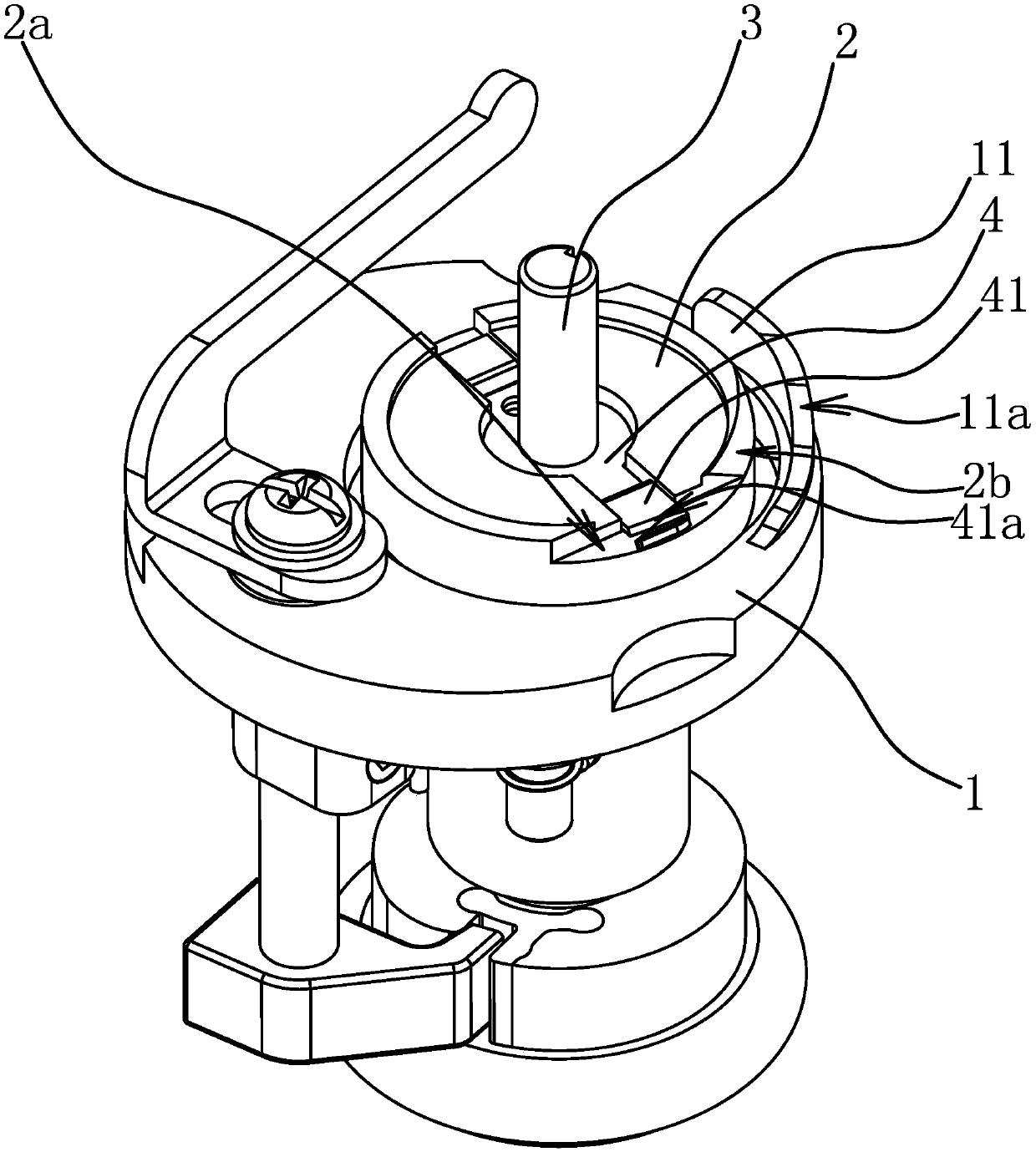

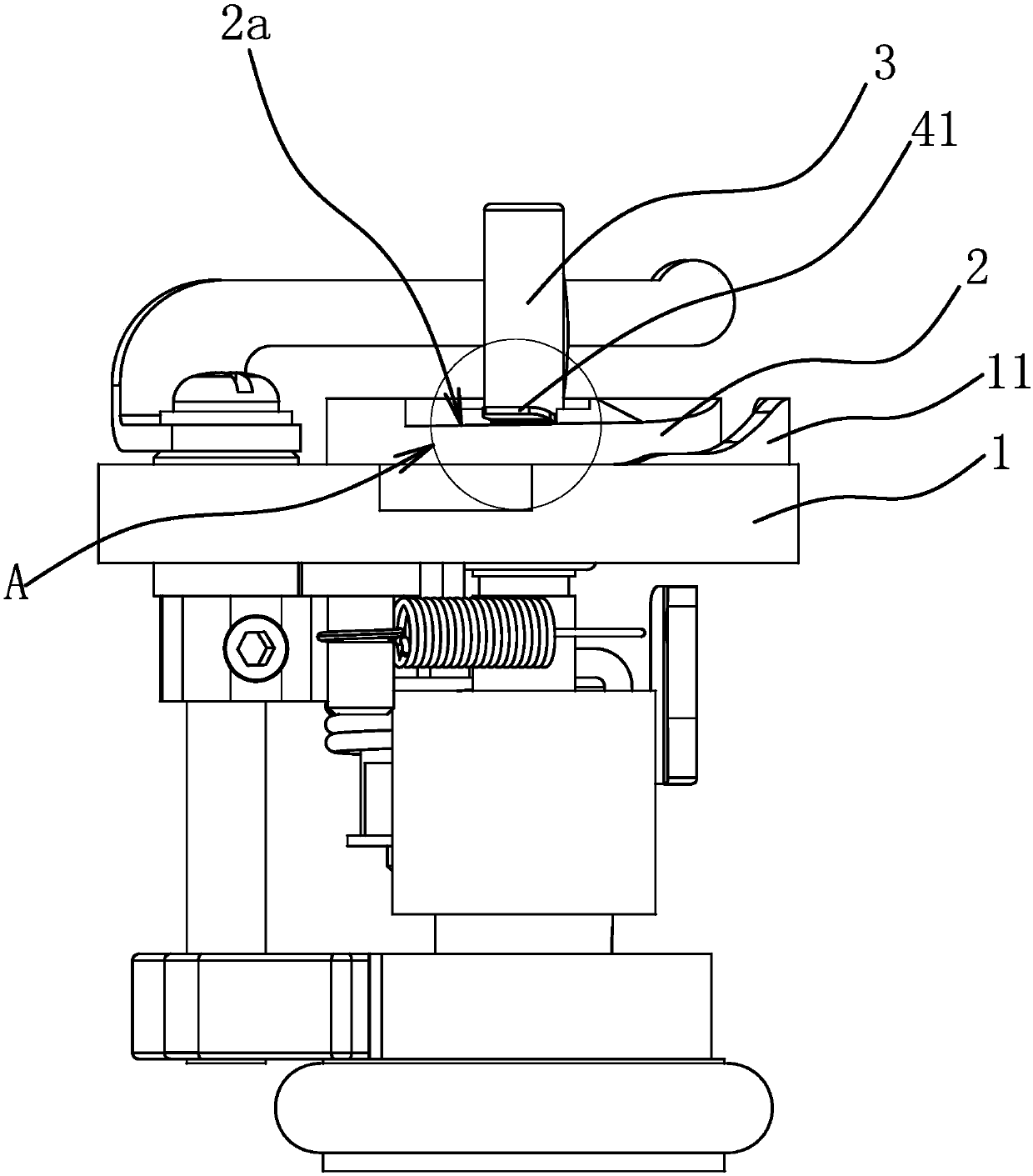

[0032] Such as figure 1 As shown, the suture is clamped on the bobbin winder through the thread gripper 8, and then the bobbin 7 is loaded on the bobbin winder to realize automatic winding. The thread winder can make the suture not easy to fall off during the thread winding process. Specifically, as figure 2 As shown, the structure of the automatic bobbin winder includes a bobbin seat 1, a cylindrical bobbin pad 2, a bobbin shaft 3 that can drive the bobbin pad 2 to rotate relative to the bobbin pad 1, and is fixedly connected to the bobbin pad 2. The secant knife 4, one end of the secant knife 4 is a secant portion 41 with a knife edge 41a on one side, the knife edge 41a is V-shaped and has an inclined downward guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com