Pile hole capping mass hole cleaning equipment and pile hole capping mass treatment method by adopting equipment

A technology for clearing holes and pile holes, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems that construction companies do not recommend the use of mud and mud pools, and achieve the effects of reducing adverse effects, lengthening lengths, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

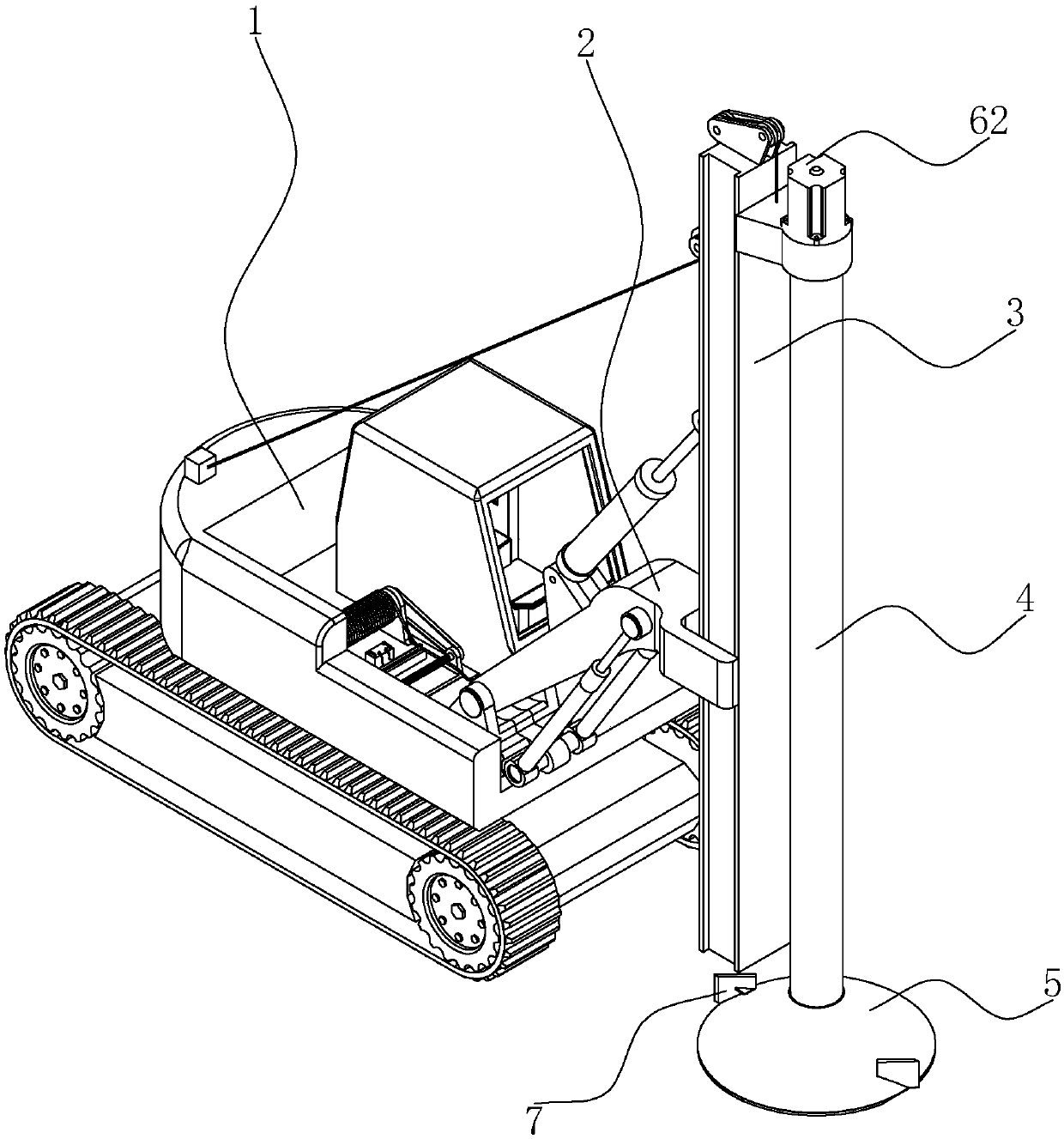

[0044] Embodiment one: a kind of pile hole floating soil clearing equipment, such as figure 1 As shown, it includes a mobile body 1, a telescopic boom 2 that is rotatably connected to the mobile body 1, a vertical arm 3 that is rotatably connected to the telescopic boom 2, and a working tube arm 4 that is slidably connected to the vertical arm 3. The mobile body 1 It can be moved as a whole, and the angle and horizontal distance of the vertical arm 3 can be adjusted through the telescopic boom 2. The working tube arm 4 is slidably connected to the vertical arm 3 and can slide up and down, which is convenient for entering and exiting the pile hole to complete the floating soil cleaning of the pile hole .

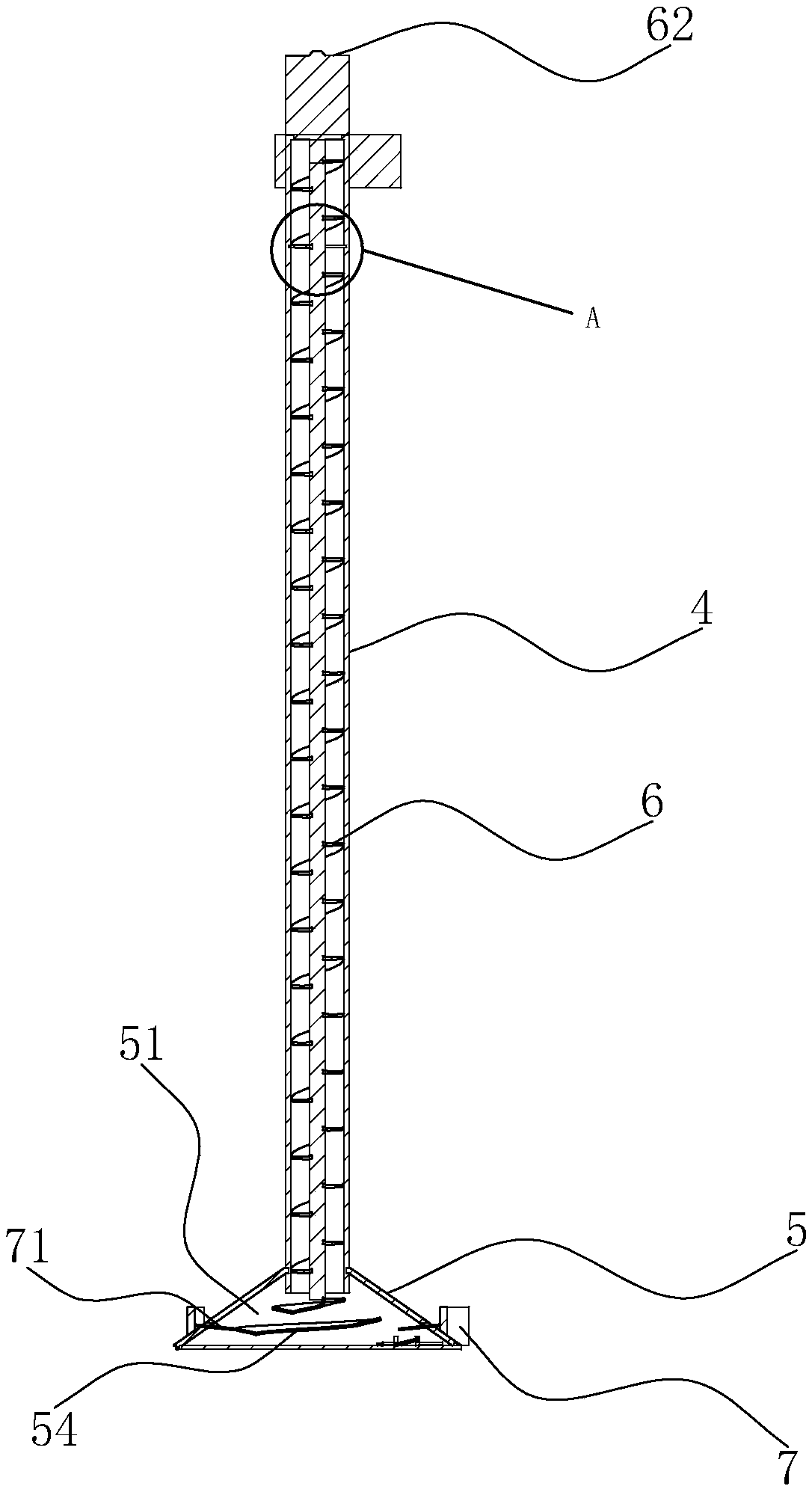

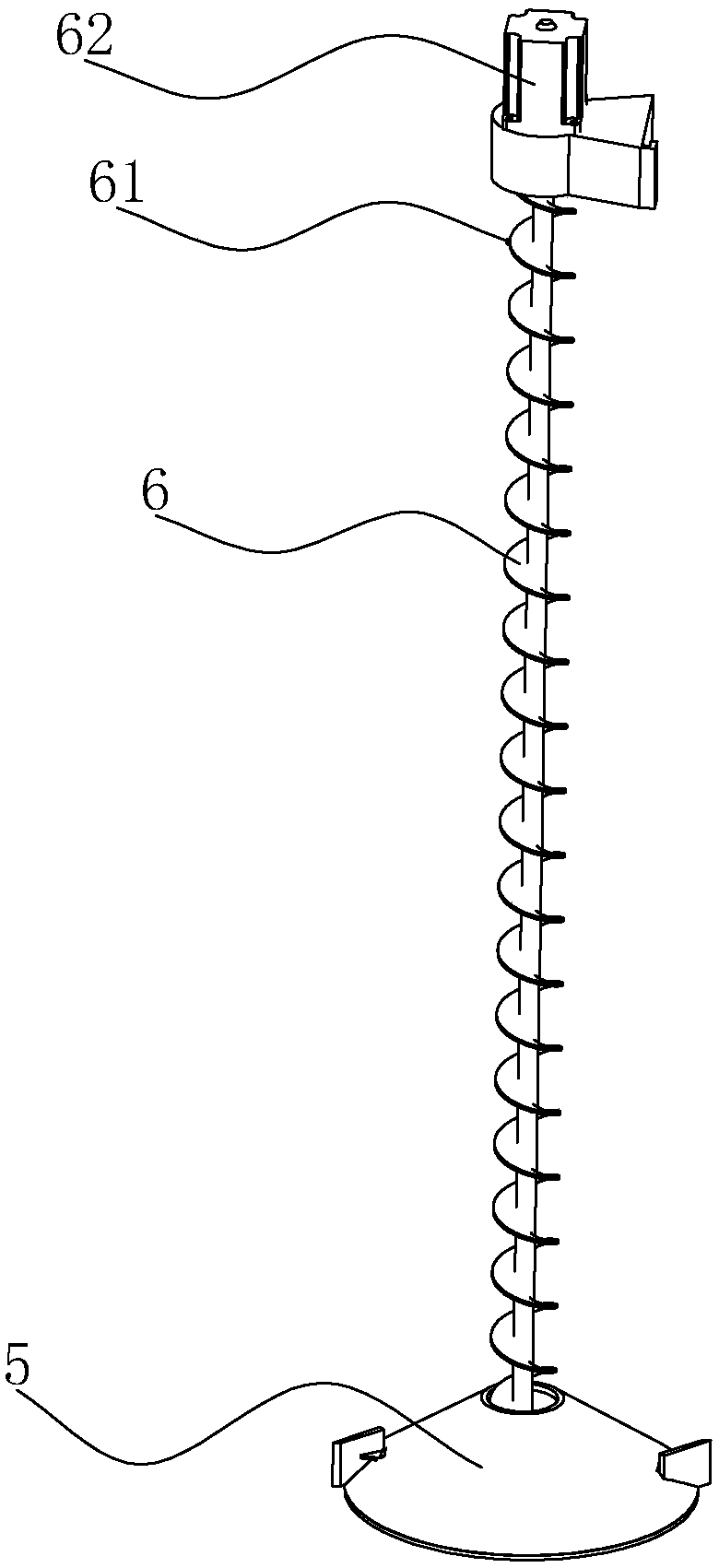

[0045] Such as figure 2 and image 3 As shown, the inside of the working pipe arm 4 is hollow and provided with a helical drive blade 6 along the length direction. The bottom end of the working pipe arm 4 is rotatably connected with a rotating hole cleaning disc 5, and the...

Embodiment 2

[0052] Embodiment two: a kind of floating soil processing method of pile hole, adopts pile hole floating soil clearing equipment in embodiment one, comprises the following steps:

[0053] S1. After the pile hole is formed and the elevation of the bottom of the pile hole has reached the design elevation, remove the drilling machine for hole construction, start to erect the hole cleaning equipment, and fix the mobile body 1 on the stable soil layer around the pile hole.

[0054] S2. Turn the telescopic boom 2 to adjust the vertical arm 3 to a vertical position, and then move the working tube arm 4 to the center axis of the pile hole directly above the pile hole. At this time, start the working motor 62 to drive the screw drive blade 6 rotates, because now spiral connecting piece 54 is plugged in the slide groove, so spiral drive vane 6 drives the rotating clear hole disc 5 to rotate synchronously. Then, the hydraulic power device (not shown in the figure) provided on the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com