Steel structure prefabricated house

A technology for prefabricated houses and steel structures, applied in building components, building structures, fire prevention, etc., can solve problems such as poor fire performance and achieve good fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

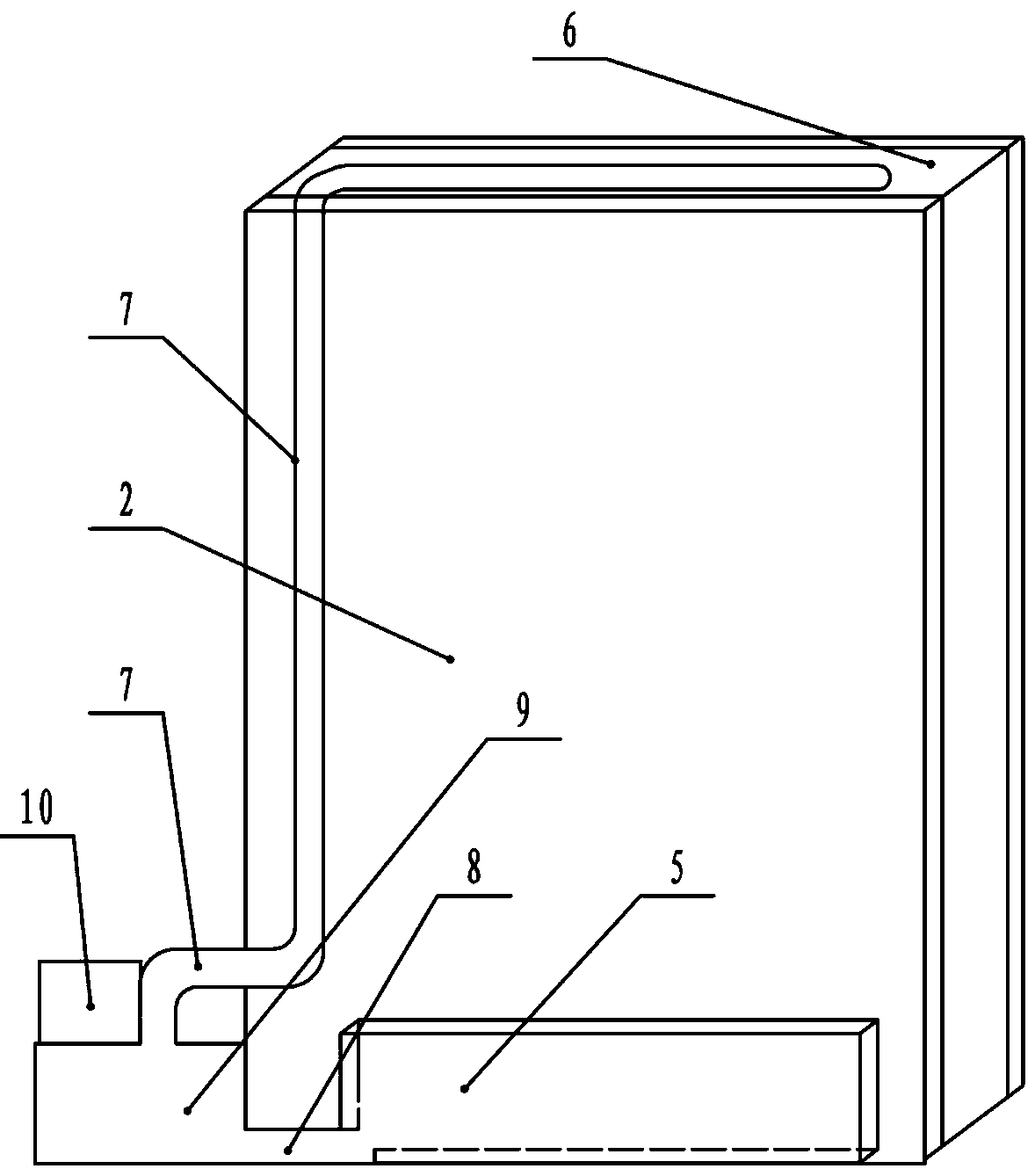

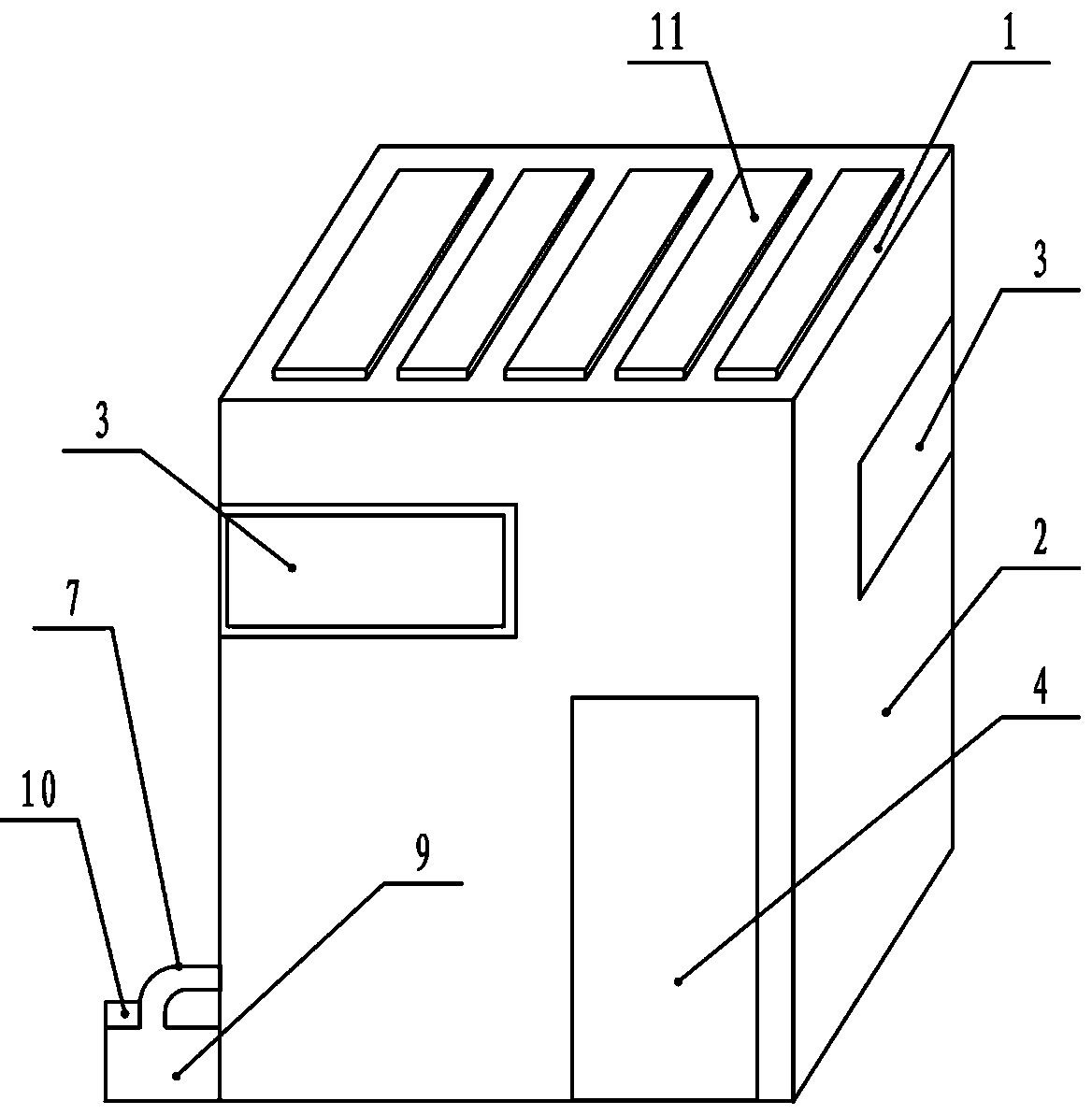

[0013] like figure 1 and 2 In the shown embodiment, this steel structure prefabricated house includes a roof 1, a wall 2, a window 3, a door 4, a water tank 9 and a water pump 10; the wall material is made of light steel skeleton and EPS polystyrene or polyurethane The core material made of foam plastic is the maintenance material, and the components are connected by bolts. The wall 2 is a two-layer maintenance material to form a sandwich 6 structure. There are water inlet pipes 7, drain pipes 8 and water tanks 5 inside the interlayer 6; There is a water tank 9 and a water pump 10 on the outside, the bottom of the water inlet pipe 7 communicates with the water tank 9, and the upper part extends to the top of the interlayer 6 structure and has a plurality of small holes on the side opposite to the ground. 8 communicates with water tank 5. A solar pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com