High-pressure triaxial acoustic testing system

A technology of acoustic testing and high pressure, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., can solve the problem of less measuring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

[0023] 1. System structure composition and working principle

[0024] 1.1 Structural Composition

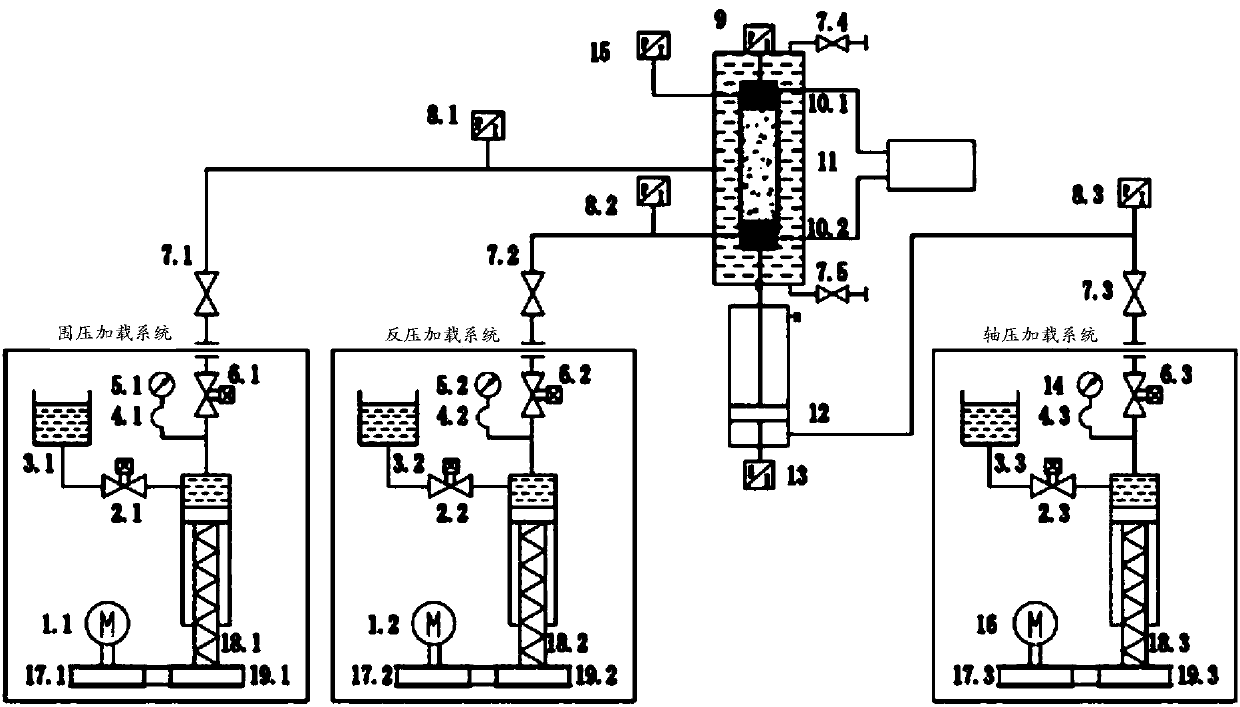

[0025] The high-voltage three-axis acoustic test system is a set of closed-loop digital servo-controlled test equipment, which has the characteristics of convenient installation, compact structure, and high control precision. Such as figure 1 As shown, the high-pressure triaxial acoustic testing system includes a pressure chamber 11, a confining pressure loading system, a back pressure loading system, and an axial pressure loading system;

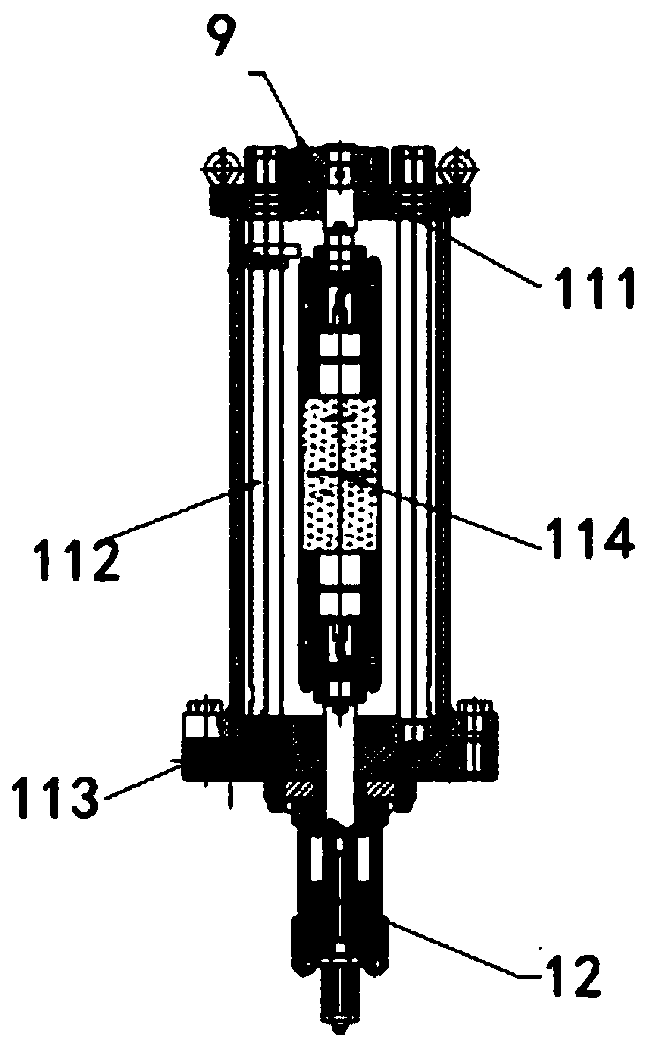

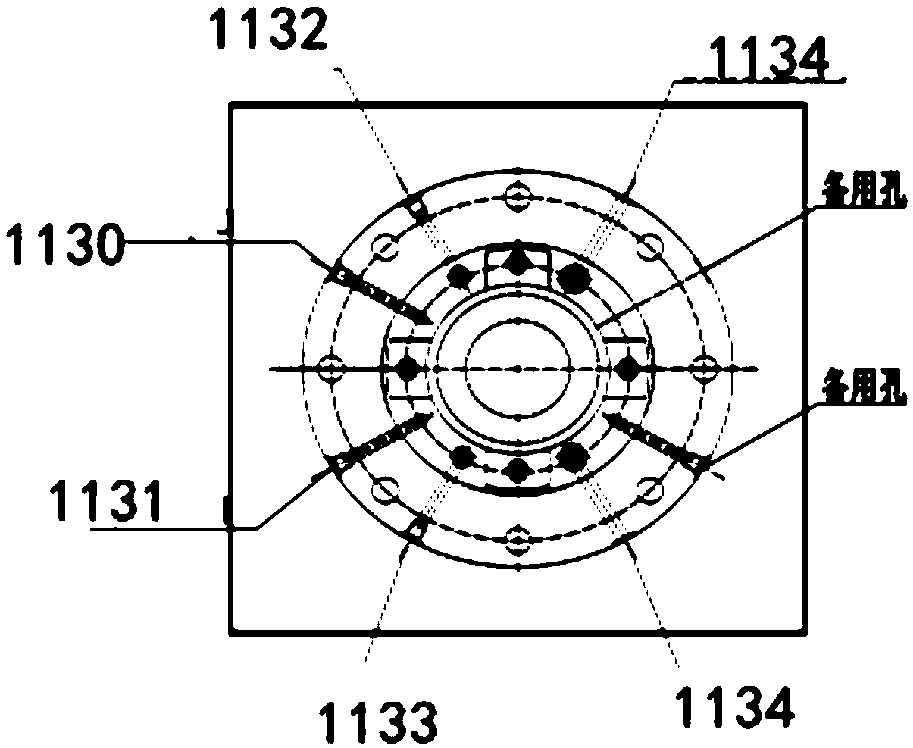

[0026] Such as figure 2 As shown, the said 11 is a vertical cabin, the upper and lower ends of the cabin have an upper end cover 111 and a lower end cover 113 respectively; the upper end cover 111 is connected with the lower end cover 113 through two connecting rods 112; There are spoke pressure transmitters 9, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com