A combined knob lever switch device

A lever switch and combined technology, which is applied in the field of combined knob and lever switch devices, can solve the problems of poor switch feel, difficult user satisfaction, and difficult assembly, so as to reduce assembly difficulty and production cost, and reduce the risk of error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is further described:

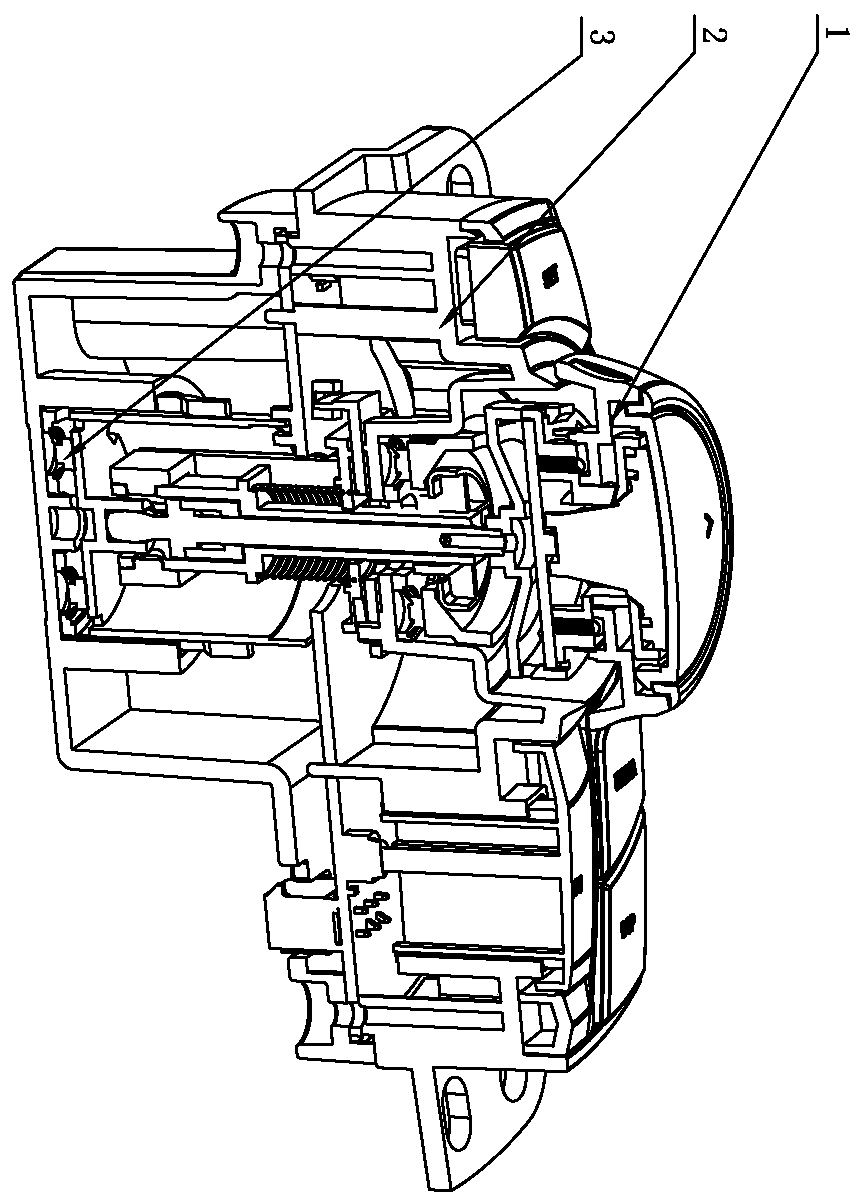

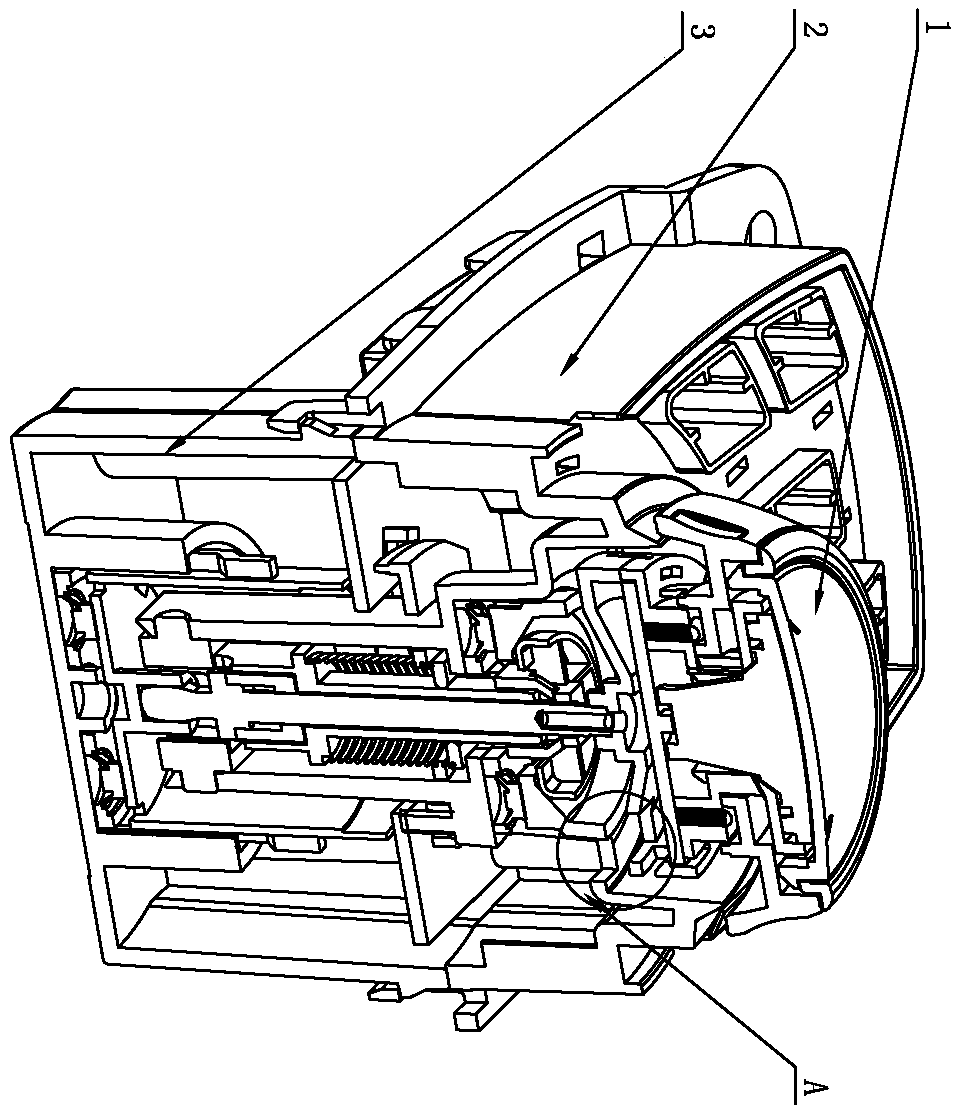

[0033] Such as Figure 1-14 A combined knob and lever switch device shown includes a knob structure 1 and a pressing structure 3, and a lever structure 2 is connected between the knob structure 1 and the pressing structure 3;

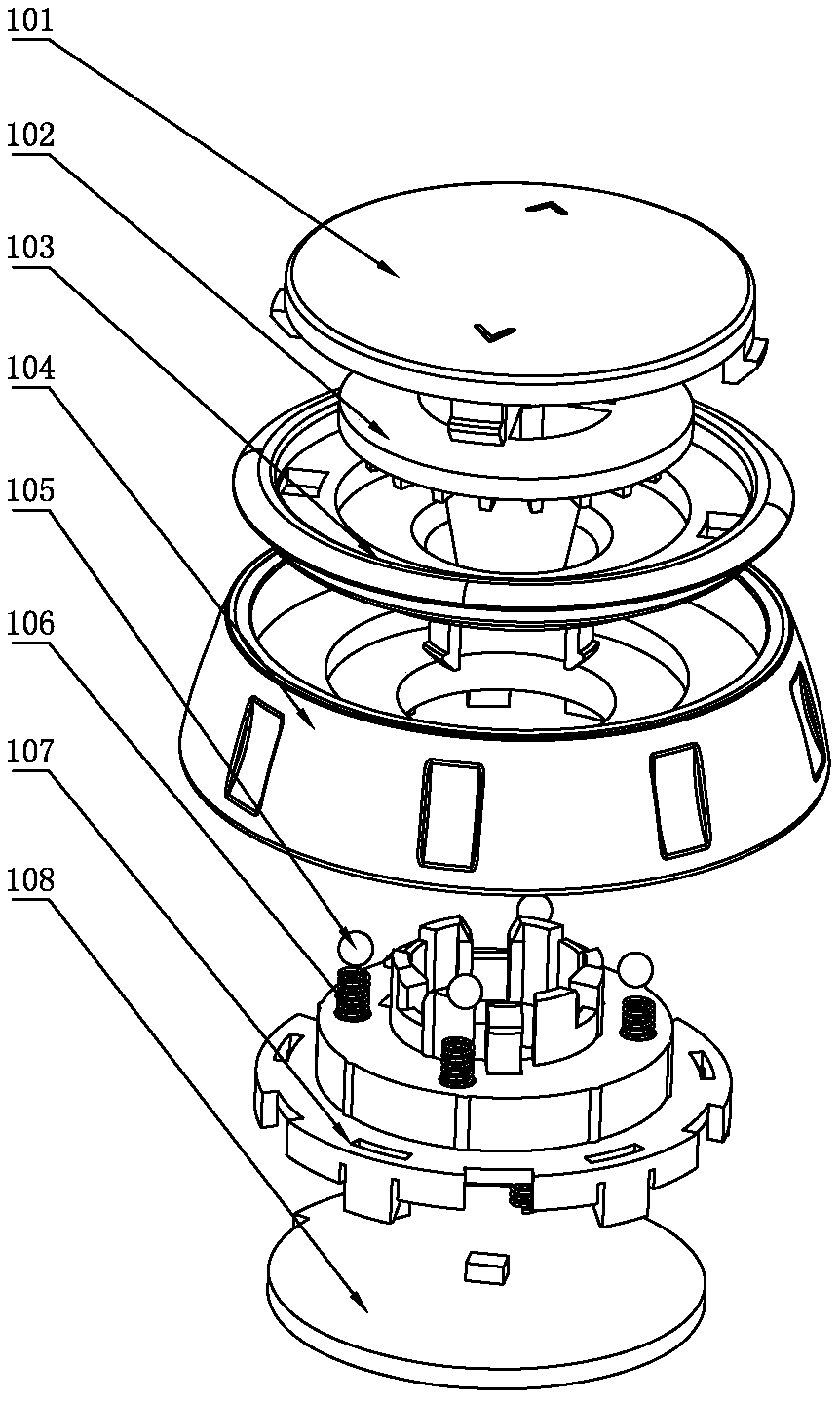

[0034] The knob structure 1 includes a circuit board 108 on which a photoelectric switch 110 is installed, the circuit board 108 is connected with the knob bracket 107, the knob bracket 107 is provided with a knob cover 104, and the knob cover 104 is provided with a light-shielding component 109, a light-shielding component 109 The photoelectric switch one 110 is turned on or off by turning the knob cover 104;

[0035] The lever structure 2 includes a main circuit board 206, a universal buckle 209 and a lever sleeve 208 arranged in the housing 202. The upper surface of the main circuit board 206 is provided with a photoelectric switch group 1 214 and a ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com