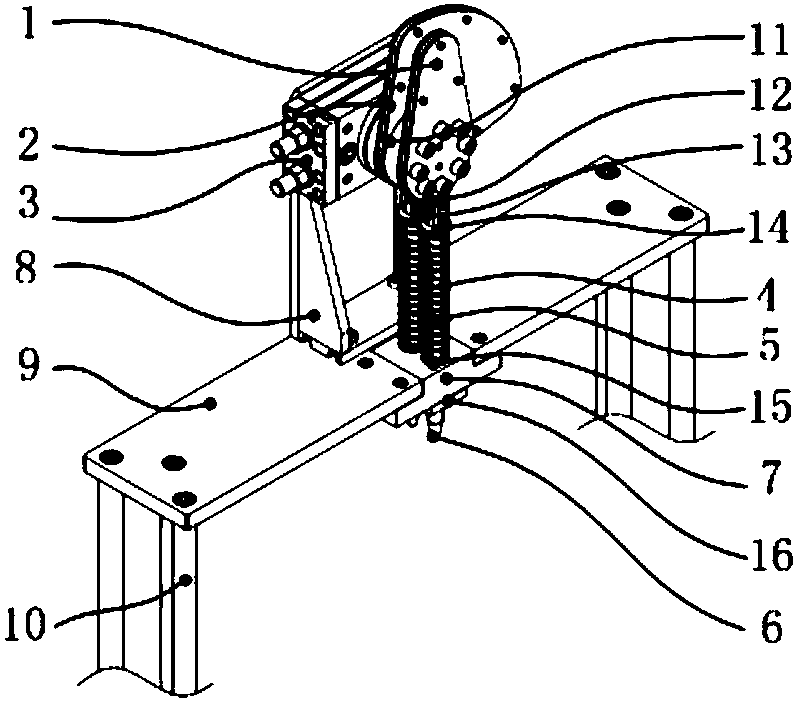

Single-drive intermittent pushing device based on double-cam mechanism

A technology of push device and rotary drive device, applied in the direction of electrical components, electrical components, etc., can solve problems such as low reliability, difficult mechanical system application, and complex control, and achieve high reliability, reduce manual errors, and reduce variability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

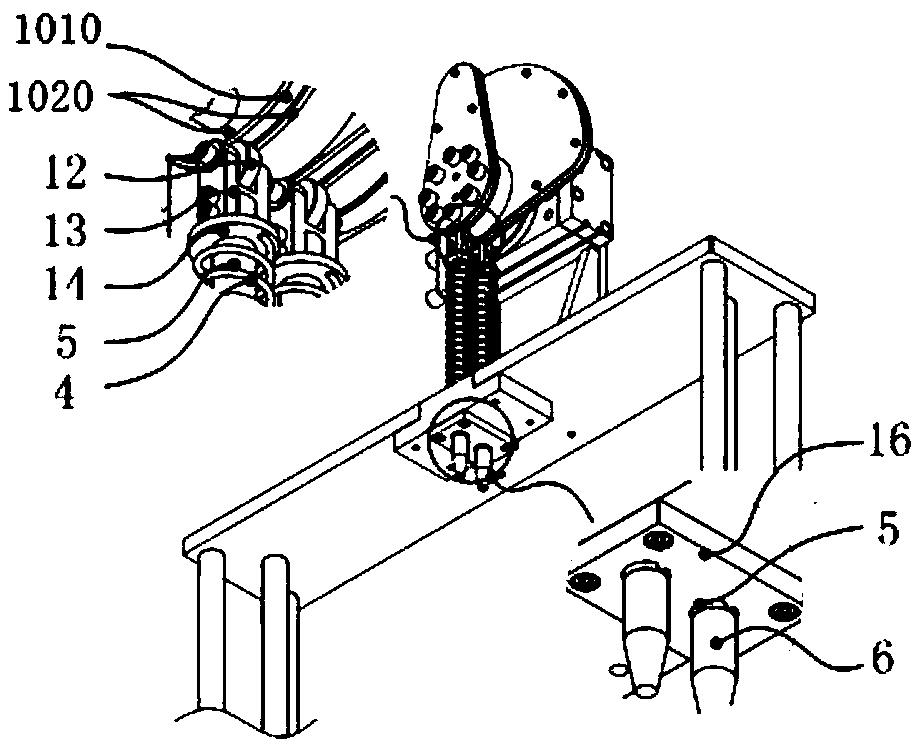

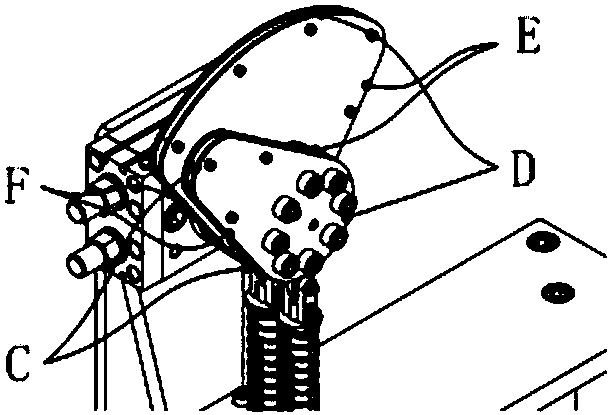

[0039] Such as figure 1 As shown, the mounting plate 9 is installed on the column 10 by screws to form a mounting frame, the mounting seat 8 is mounted on the mounting plate 9 by screws, the rotating drive device 3 is installed on the mounting seat 8, and the first cam is installed on the rotating shaft. 2 and the second cam 1, the second cam 1 is on the outside. Bearing housing 7 and linear bearing 15 tightly matched with bearing housing 7 are installed on the lower mounting frame of first cam 2 and second figure cam 1, two guide shafts 5 pass through linear bearing 15 and are set, and its lower end is fixedly connected with The push head 6 has a pulley frame 13 installed on the upper end, and a spring retainer 14 is installed between the pulley frame 13 and the guide shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com