Ultrasonic hydrocarbon cleaning machine and method for clearing water-soluble metalworking liquid through same

A hydrocarbon cleaning and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as high waste water costs, environmental damage, and large amounts of waste water, and achieve high cost savings , Avoid environmental damage, save time and effort in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0027] The invention discloses an ultrasonic hydrocarbon cleaning machine and its method for cleaning water-soluble cutting fluid, which uses hydrocarbon solvent cleaning instead of water-based solvent to clean the cutting fluid, does not generate waste water, and recycles the hydrocarbon solvent to save energy. Environmental friendly.

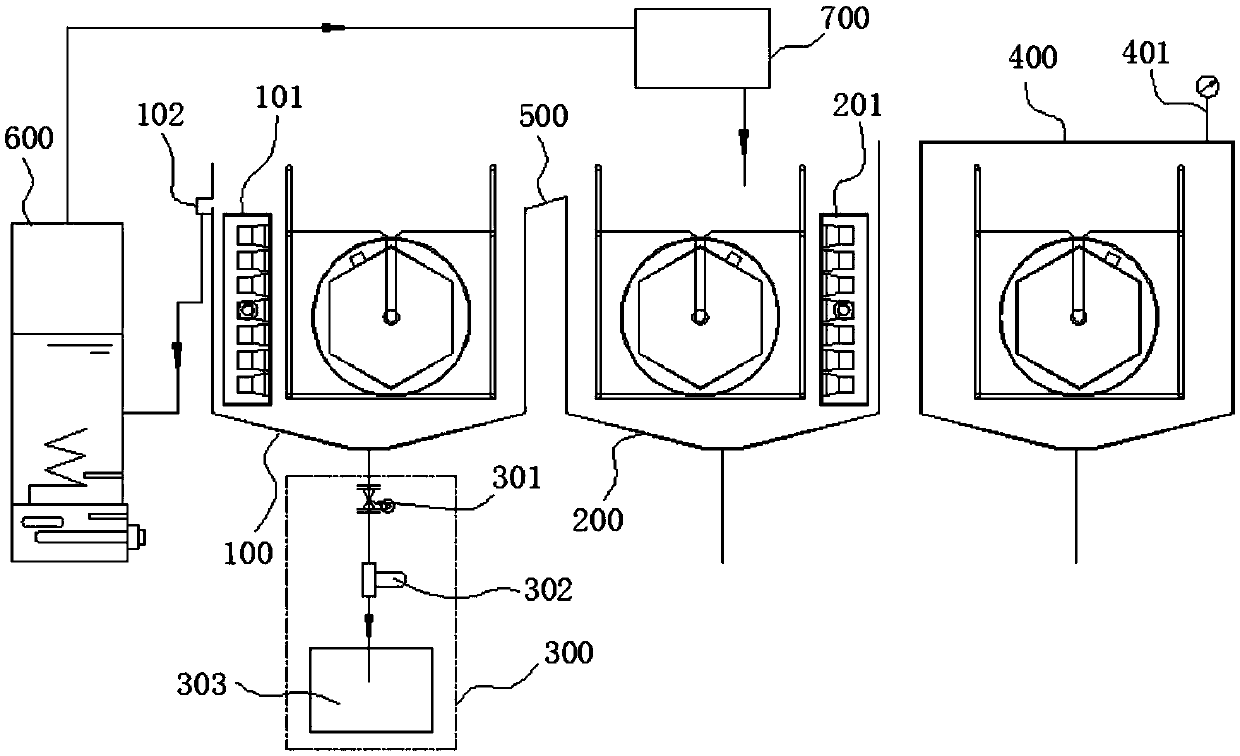

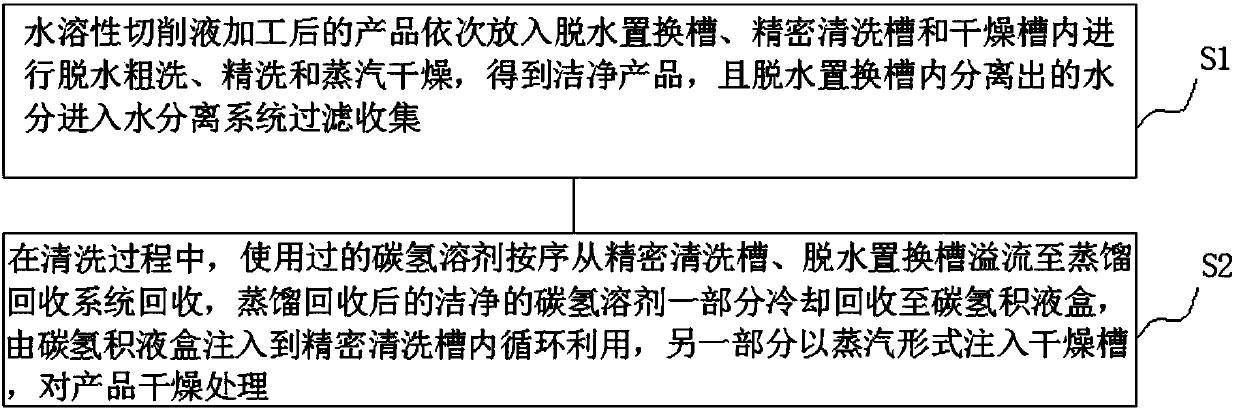

[0028] combine figure 1 and figure 2 As shown, an ultrasonic hydrocarbon cleaning machine disclosed in the embodiment of the present invention includes a dehydration replacement tank 100, a precision cleaning tank 200, a water separation system 300, a drying tank 400 and a closed-loop hydrocarbon recovery system, and a water-soluble cutting fluid The processed products are placed in the dehydration replacement tank 100, the precision cleaning tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com